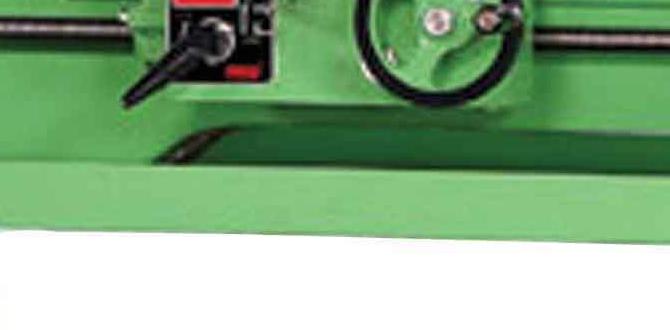

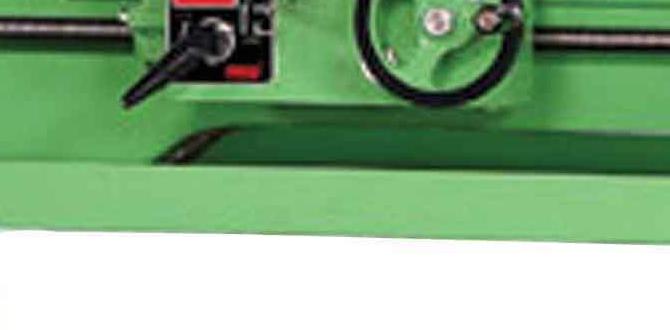

Have you ever seen a metal lathe in action? These machines are amazing tools used to shape metal into various parts. But what happens when they don’t work well? This is where lathe restoration comes in. Restoring a lathe can be a rewarding project.

One of the most critical parts of a lathe is the gear train. The gear train helps the machine turn metal with precision. If the gears are worn out or damaged, the lathe won’t function correctly. Can you imagine trying to shape metal with a broken gear train?

Many enthusiasts start their journey with a rusty old metal lathe. With some patience and knowledge, they can bring these machines back to life. It’s like finding treasure! The feeling of success after restoring a lathe makes all the hard work worth it.

In this article, we will explore the steps in lathe restoration, focusing on the metal lathe gear train. You’ll learn tips and tricks to help ensure your restoration goes smoothly. Ready to dive into the world of lathes? Let’s get started!

Lathe Restoration: Metal Lathe Gear Train Breakdown Guide

Lathe Restoration: Exploring the Metal Lathe Gear Train

Restoring a metal lathe can be an exciting journey. The gear train is vital for smooth operation. Understanding how gears work together helps in repairs and improvements. Did you know that cleaning old gears can significantly enhance their performance? By following proper steps for restoration, you can breathe new life into your lathe. This process not only saves money but also strengthens your skills as a maker. Dive into the fascinating world of lathes and discover the possibilities!Understanding Metal Lathes and Their Gear Trains

Definition and function of metal lathes. Importance of gear trains in metal lathe operation.Metal lathes are machines that shape metal into various forms. They rotate the metal while cutting tools shape it. This process helps create products like screws and rods. The gear train in a lathe is very important. It controls the speed and direction of the rotation. A strong gear train makes the lathe work better. Think of it like the engine of a car; if it’s strong, the car runs smoothly.

What is the role of gear trains in metal lathes?

Gear trains help adjust the speed also allow for smoother operation in metal lathes. They manage how fast the machine turns and how much power goes into it. This control is vital for making precise cuts. Without gear trains, working with a lathe would be very difficult.

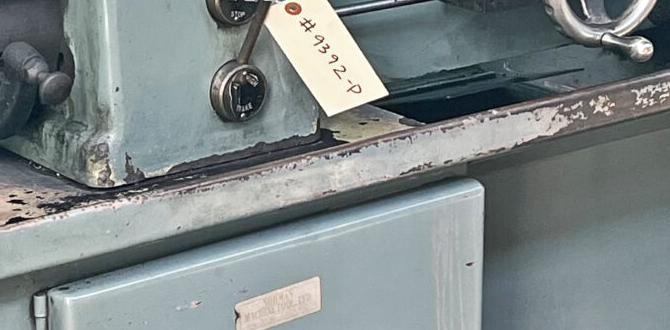

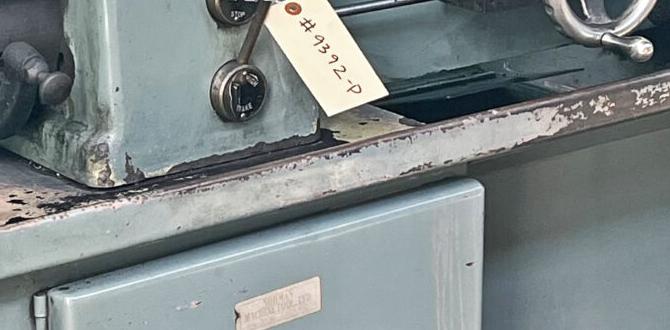

Identifying Common Issues in Lathe Gear Trains

Signs of wear and tear in gear systems. Common mechanical failures and their causes.Keeping an eye on your lathe gear train is key to a smooth-running machine. Look for odd noises or strange vibrations; these may hint at wear and tear. Signs like chipped teeth on gears or loose connections can lead to major headaches later. According to experts, most mechanical failures happen due to poor lubrication or dirt buildup. So, let’s keep it clean! Here’s a quick guide:

| Issue | Possible Cause |

|---|---|

| Chipped Gear Teeth | Poor alignment or impact |

| Slipping Gears | Worn out parts |

| Strange Noises | Lack of lubrication |

Stay vigilant, and your lathe will thank you by working like a charm. Keeping it in tip-top shape is like feeding a pet—if you don’t take care of it, it’ll bark at you!

Step-by-Step Guide to Disassembling the Gear Train

Preparing the lathe for disassembly. Detailed steps for removing gears and components.First, get your lathe ready. Unplug it! Safety first, friends. Grab your tools and a cozy spot to work. Take notes as you go, because memory isn’t always reliable, especially when gears start spinning! Remove the cover to reveal the gear train, and get ready to play a game of “what goes where.”

Now, let’s remove those gears, one by one. Start with the smallest gear and work your way up. Use the table below to keep track of what you’ve taken off.

| Gear Number | Component | Notes |

|---|---|---|

| 1 | Small Gear | Remove gently! |

| 2 | Medium Gear | Check for wear. |

| 3 | Large Gear | Watch your fingers! |

After each gear comes off, clean it. A happy gear is a clean gear! Once everything is off, you’re ready for restoration. With a little time and care, you’ll have your lathe running like new in no time.

Cleaning and Inspecting Gear Components

Best practices for cleaning metal gears. How to inspect for damage and wear.Cleaning metal gears is vital for smooth operation. Start by wiping down the surfaces with a soft cloth. You can use soapy water for tough grime. Rinse and dry well! Inspect each gear for damage. Look for chips, cracks, or unusual wear. A magnifying glass can help spot tiny issues. Remember, even a small flaw can mess up the whole machine! Here’s a quick guide:

| Step | Action |

|---|---|

| 1 | Wipe surfaces with a soft cloth. |

| 2 | Use soapy water for stubborn dirt. |

| 3 | Rinse and dry completely. |

| 4 | Check for chips or cracks. |

| 5 | Use a magnifying glass for small damage. |

Taking these steps keeps your lathe running like a well-oiled machine—literally!

Repairing or Replacing Gear Components

When to repair vs. when to replace gears. Sourcing replacement parts for ancient lathes.Sometimes gears wear out or break. It’s important to know when to fix them or when to get new ones. If the gear is slightly damaged, repairing it might be best. But if it’s cracked or missing parts, replacement is better. For ancient lathes, finding parts can be tricky. Here are some tips:

- Check online stores that specialize in old tools.

- Visit local hardware shops; they might have what you need.

- Look for online forums. Other users often share tips.

How do you know if a gear needs repair or replacement?

If a gear has small scratches, it can often be repaired. If it has big cracks, you should replace it. Look at the overall condition. Sometimes, it’s best to replace a bad gear instead of spending time and money fixing it.

Reassembling the Gear Train

Stepbystep reassembly procedure. Tips for ensuring proper alignment and function.Time to put the pieces back together! Follow these fun steps for a smooth reassembly. First, place the base on a flat surface. Next, carefully align the gears and check the teeth. Misaligned gears can lead to noise, or worse, a bad time! Give each part a gentle twist to test the fit. Don’t forget to tighten screws—you don’t want gears flying off like rogue marbles!

| Step | Tip |

|---|---|

| 1. Align Gears | Use a flashlight to check tooth alignment. |

| 2. Test Fit | Turn the gears gently to feel for resistance. |

| 3. Tighten Screws | Remember: snug, not Hulk-smash! |

With a little care, your gear train will purr like a content cat. Enjoy your newly restored lathe and happy machining!

Tuning and Calibrating the Restored Lathe

Importance of tuning for optimal performance. Methods for calibration and testing accuracy.Tuning a lathe is key for its best performance. When it’s set up correctly, it works smoothly. This makes your projects better and more precise. You can test accuracy using simple methods. Try the following:

- Check the speed settings. Ensure they match the manual.

- Use a dial indicator to measure movement.

- Calibrate the tool post for exact cuts.

- Run a test piece to see how it works.

Fine-tuning is vital. It saves time and materials. A well-tuned lathe makes work fun and easy!

Why is tuning important for my lathe?

Tuning ensures your lathe operates at its best. It helps in making precise cuts and reduces mistakes.

Maintaining Your Restored Lathe for Longevity

Routine maintenance tasks and schedules. Tips for preventing future gear train issues.Taking care of your restored lathe is key for a long life. Start with simple tasks like cleaning and oiling. Schedule these jobs every month to keep things running smoothly. Think of it as your lathe’s spa day! Preventing gear train issues is easy too; check for wear and tear often. And remember, if a gear squeaks, it’s time to tweak!

| Routine Maintenance Task | Frequency |

|---|---|

| Clean and Oil | Monthly |

| Check Gear Condition | Every 3 Months |

| Tighten Loose Parts | As Needed |

Following this schedule will help keep your lathe in tip-top shape. Think of it as great insurance against future problems! Remember, a well-cared lathe is a happy lathe.

Resources and Community Support for Lathe Enthusiasts

Recommended literature and manuals for further learning. Online forums and communities for restoration tips and support.Finding the best resources can make your lathe journey easier and more fun! Start with some classic literature and manuals. They can turn you into a lathe wizard in no time. Don’t forget online forums where you can ask questions and share tips with other enthusiasts. It’s like having a bunch of friends who love lathes as much as you do! Here’s a handy table to kick off your search:

| Resource Type | Recommended Titles |

|---|---|

| Books | The Metal Lathe, Lathework |

| Manuals | Lathe Basics, Guidelines for Restoration |

| Online Forums | The Home Shop Machinist, Practical Machinist |

Joining these communities isn’t just about learning. It’s about laughing at the occasional blunders like accidentally turning your lathe into a spaghetti maker! So, grab those manuals, join the chats, and let’s keep those gears turning!

Conclusion

In conclusion, restoring a metal lathe and its gear train can be exciting and rewarding. You learn valuable skills and understand how machines work. Start by cleaning parts, checking for damage, and replacing worn gears. Don’t hesitate to research and seek help if needed. With practice, you can create amazing projects. Let’s keep exploring and learning together!FAQs

What Are The Common Signs Of Wear Or Damage In A Metal Lathe Gear Train That Indicate A Need For Restoration?You can spot worn or damaged gears in a metal lathe by looking for a few signs. If you see cracks or chips on the gears, that’s a problem. Gears that no longer fit together well can make loud noises. If the lathe shakes or doesn’t work smoothly, it might need fixing too. Always check for rust or dirt that could cause trouble.

How Can One Properly Clean And Lubricate The Gears In A Lathe Gear Train To Ensure Optimal Performance?To clean the gears in a lathe, start by turning off the machine. Use a soft cloth or brush to wipe away dust and dirt. Next, use a light oil or grease made for machines to lubricate the gears. Make sure to apply it evenly and avoid too much. This will help the gears work smoothly and last longer.

What Tools And Materials Are Typically Required For Restoring A Metal Lathe’S Gear Train?To restore a metal lathe’s gear train, you will need some tools and materials. First, get a wrench to help you remove the parts. Then, use screwdrivers to take out screws. You might need sandpaper to clean the gears. Lastly, have some oil to make everything run smoothly again after you put it all back together.

How Do Different Gear Ratios In The Lathe’S Gear Train Affect Machining Capabilities And Speed?Different gear ratios in a lathe change how fast the machine turns. When we use a low gear ratio, the lathe spins slowly but has more power. This helps us make detailed cuts. A high gear ratio makes it spin faster, which is great for smoother surfaces but less power. So, we can adjust gears to fit what we want to make.

What Step-By-Step Approach Should Be Taken When Disassembling And Reassembling The Gear Train During A Restoration Project?When you disassemble the gear train, start by taking pictures of everything. This helps you remember how to put it back together. Next, carefully remove each piece one at a time, keeping them in order. Use small bags to hold screws and tiny parts. When reassembling, follow your pictures and put everything back the same way you took it apart. Make sure each piece fits snugly in its spot.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Common Signs Of Wear Or Damage In A Metal Lathe Gear Train That Indicate A Need For Restoration? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can spot worn or damaged gears in a metal lathe by looking for a few signs. If you see cracks or chips on the gears, that’s a problem. Gears that no longer fit together well can make loud noises. If the lathe shakes or doesn’t work smoothly, it might need fixing too. Always check for rust or dirt that could cause trouble.”}},{“@type”: “Question”,”name”: “How Can One Properly Clean And Lubricate The Gears In A Lathe Gear Train To Ensure Optimal Performance? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To clean the gears in a lathe, start by turning off the machine. Use a soft cloth or brush to wipe away dust and dirt. Next, use a light oil or grease made for machines to lubricate the gears. Make sure to apply it evenly and avoid too much. This will help the gears work smoothly and last longer.”}},{“@type”: “Question”,”name”: “What Tools And Materials Are Typically Required For Restoring A Metal Lathe’S Gear Train? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To restore a metal lathe’s gear train, you will need some tools and materials. First, get a wrench to help you remove the parts. Then, use screwdrivers to take out screws. You might need sandpaper to clean the gears. Lastly, have some oil to make everything run smoothly again after you put it all back together.”}},{“@type”: “Question”,”name”: “How Do Different Gear Ratios In The Lathe’S Gear Train Affect Machining Capabilities And Speed? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Different gear ratios in a lathe change how fast the machine turns. When we use a low gear ratio, the lathe spins slowly but has more power. This helps us make detailed cuts. A high gear ratio makes it spin faster, which is great for smoother surfaces but less power. So, we can adjust gears to fit what we want to make.”}},{“@type”: “Question”,”name”: “What Step-By-Step Approach Should Be Taken When Disassembling And Reassembling The Gear Train During A Restoration Project? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When you disassemble the gear train, start by taking pictures of everything. This helps you remember how to put it back together. Next, carefully remove each piece one at a time, keeping them in order. Use small bags to hold screws and tiny parts. When reassembling, follow your pictures and put everything back the same way you took it apart. Make sure each piece fits snugly in its spot.”}}]}