Have you ever wondered how to stay safe while using a metal lathe? Many people enjoy working with metal, but safety should always come first. A lathe safety checklist can help keep you and your workspace safe.

Imagine turning a piece of metal on a lathe. It spins fast, and one mistake can lead to accidents. That’s why it’s crucial to know how to set up your metal lathe controller board properly. A small error could result in serious harm or damage.

Here’s a fun fact: Did you know that checking your tools and workspace can prevent almost half of all accidents? It’s true! By using a proper safety checklist, you prepare yourself for a safer and more enjoyable experience. In this article, we’ll explore essential tips and guidelines for using a lathe safely.

Essential Lathe Safety Checklist For Metal Lathe Controller Board

Lathe Safety Checklist: Metal Lathe Controller Board

Proper safety measures are crucial when using a metal lathe. A lathe safety checklist ensures you remain safe while cutting and shaping metal. Key points include wearing protective gear, securing workpieces, and keeping hands away from moving parts. Did you know that a simple slip can lead to serious injuries? Inspect the lathe controller board for any issues before starting. This helps you avoid accidents and maintain a safe working environment. Stay safe and work smart!Importance of Lathe Safety

Understanding the risks associated with metal lathes. The impact of safety on productivity and equipment lifespan.Using metal lathes can be risky. Safety matters because it keeps you safe and your tools working longer. When you protect yourself, you avoid bad accidents. This help makes your projects smoother and faster. Plus, taking care of your equipment means fewer repairs and a longer life for your lathe. Remember: safe practices lead to better results!

Why is lathe safety crucial?

Lathe safety is important for several reasons:

- It helps prevent accidents.

- It improves work speed.

- It extends the life of your equipment.

Basic Safety Gear and Equipment

Personal protective equipment (PPE) recommendations. Importance of proper clothing and accessories.Staying safe while using machines is super important! You should wear personal protective equipment (PPE) like gloves, goggles, and ear protection. This keeps your body safe from danger. Proper clothing, like tight-fitting shirts and long pants, prevents snagging. Accessories, like steel-toed boots, protect your feet. Follow these tips:

- Wear gloves to protect your hands.

- Put on goggles for eye safety.

- Use ear protection to guard against noise.

- Choose sturdy shoes to shield your feet.

What is PPE and why is it important?

PPE stands for personal protective equipment. It helps keep you safe while working. Without it, you risk injury. Using proper PPE can prevent serious accidents and keep you healthy.

Pre-Operational Safety Checks

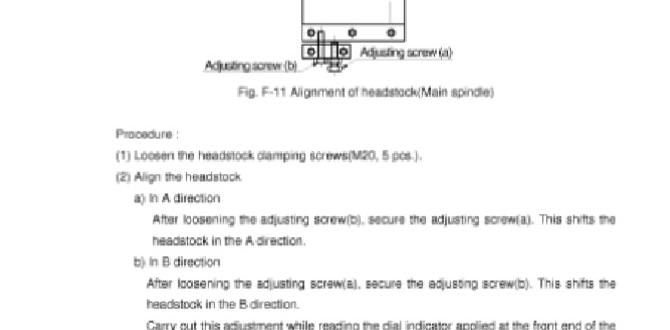

Checklist for inspecting the lathe before use. Importance of ensuring proper tooling and workpiece setup.Before using a lathe, it’s vital to check everything carefully. A safety checklist helps keep everyone safe. Here are some key checks:

- Examine the lathe for any damage.

- Check that tools are sharp and properly fitted.

- Ensure the workpiece is secure and aligned.

- Inspect safety guards and controls.

Doing these checks ensures proper tooling and workpiece setup. This helps prevent accidents and improves the quality of work.

Why is a lathe checklist important?

A lathe checklist is important because it helps identify potential issues before they happen. This keeps operators safe and ensures the lathe runs smoothly.

What should be included in a lathe safety checklist?

- Machine condition

- Tool sharpness

- Workpiece setup

- Safety features

Operational Safety Procedures

Best practices during lathe operation. Common mistakes to avoid while using a metal lathe.Using a metal lathe safely is very important. Here are some best practices:

- Always wear protective gear, like goggles and gloves.

- Check the machine and tools before starting.

- Keep hands away from moving parts.

- Never rush. Take your time to ensure safety.

Common mistakes can lead to accidents. Avoid these:

- Skipping safety checks.

- Ignoring strange sounds or vibrations.

- Using dull or damaged tools.

- Not knowing how to stop the machine quickly.

What are some common mistakes to avoid while using a metal lathe?

The main mistakes to avoid are skipping safety checks, using dull tools, and ignoring strange sounds. These habits can lead to accidents and injuries.

Post-Operational Safety Steps

Guidelines for cleaning and maintaining a lathe after use. Importance of documenting operational issues or concerns.After using a lathe, it’s crucial to clean and maintain it properly. Start by removing any chips and debris from the machine. Next, wipe down the surfaces with a soft cloth. Proper maintenance helps prevent damage and keeps the lathe running smoothly.

Also, document any issues you notice during use. This helps catch problems early and ensures safety. Keeping a record is like having a safety net for future use.

- Check the oil levels.

- Inspect belts and cords for wear.

- Make note of any strange noises or vibrations.

Why is documentation important?

Documenting issues helps maintain safety and efficiency. It allows you to track problems and solutions over time. This practice creates a safer work environment for everyone.

Emergency Procedures and First Aid

Steps to take in case of an accident. Basic first aid measures for common lathe injuries.In case of an accident, stay calm and act quickly. First, turn off the machine and alert others nearby. If someone is hurt, check for serious injuries. Call for help if needed. Here are some basic first aid steps for common lathe injuries:

- Minor Cuts: Clean the wound, apply antiseptic, and cover it with a bandage.

- Burns: Cool the burn under running water. Cover it with a sterile cloth.

- Pinched Fingers: Do not pull or yank. Keep them still and apply an ice pack.

Remember, safety first! Knowing these steps can help save lives.

What should you do if someone gets hurt on a lathe?

If someone gets hurt, turn off the lathe and call for help immediately. Make sure to check their injuries and provide first aid if safe to do so.

Training and Safety Awareness Programs

Importance of training for operators. Resources for ongoing safety education in machine operation.Operators need solid training to use machines safely. This training helps prevent accidents and mistakes. Regular safety education keeps everyone informed about new tools and techniques. It’s like learning to ride a bike—practice makes perfect! Check out the table below for great resources:

| Resource | Description |

|---|---|

| Workshops | Hands-on learning with experts. |

| Online Courses | Learn at your own pace, maybe in pajamas! |

| Safety Manuals | Your best friend in the workshop. |

Staying safe is no joke! Remember, an informed operator is a happy operator; don’t let safety slip through the cracks!

Common Hazards and Risk Mitigation Strategies

Identifying hazards specific to metal lathe operations. Techniques for minimizing risk and promoting safety awareness.Using a metal lathe can be exciting, but it also has some sneaky hazards. A common mishap is flying debris. To avoid this, wear safety glasses and keep your workspace clear. Another danger is getting caught in moving parts. Always tie back long hair and roll up those sleeves! Stay alert and remind others to do the same—lathes don’t have a sense of humor when it comes to safety. Here’s a quick checklist:

| Hazard | Mitigation Strategy |

|---|---|

| Debris | Wear safety glasses |

| Catching clothing/hair | Secure loose items |

| Poor training | Learn the machine properly |

By following these tips, you can turn that metal lathe into your best metal friend instead of a troublemaker!

Conclusion

In conclusion, using a lathe safely is crucial. A safety checklist helps you remember important steps. Always check your metal lathe controller board before starting. This prevents accidents and keeps you safe. We encourage you to create your own checklist and review it regularly. For more tips on lathe safety, check out reliable resources or guides. Stay safe and happy machining!FAQs

Here Are Five Related Questions On The Topic Of Lathe Safety Checklist For A Metal Lathe Controller Board:A lathe safety checklist helps keep you safe when using a metal lathe. You should always wear safety glasses to protect your eyes. Make sure to keep your hair tied back and wear snug clothing. Check the machine and tools before you start to make sure they work well. Finally, never rush—take your time to work carefully!

Sure! Please provide the question you would like me to answer.

What Specific Safety Features Should Be Included On A Metal Lathe Controller Board To Protect The Operator During Use?To keep you safe while using a metal lathe, the controller board should have a few important safety features. First, it should have an emergency stop button that you can reach quickly. This button stops the machine right away if there’s a problem. Second, there should be warning lights that flash when the machine is running. Finally, using covers or shields can protect you from flying metal pieces. These features help us work safely!

How Can Operators Ensure That The Emergency Stop Functions Correctly On Their Metal Lathe Controller Board?To make sure the emergency stop works on a metal lathe, you should first check the button regularly. Make sure it’s not stuck and can move freely. Test the emergency stop by pressing it when the machine is on. If it stops the lathe right away, it’s working. Lastly, always read the manual for safety tips!

What Pre-Operation Checks Should Be Performed On The Controller Board Of A Metal Lathe To Ensure Safe Functionality?Before using the metal lathe, you should check a few important things on the controller board. First, make sure all the wires are connected tightly and not damaged. Next, look for any signs of dirt or dust and clean it if needed. Then, check the buttons and switches to see if they work correctly. Finally, ensure the power light is on, showing it’s ready to go!

How Do The Programming Settings On A Lathe Controller Board Affect Operator Safety During Machining Operations?The programming settings on a lathe controller board help keep you safe while working. They control things like speed and power of the machine. If you set these correctly, the machine will run safely and smoothly. This helps avoid accidents, like getting hurt by fast-moving parts. Always check your settings to stay safe!

What Are The Best Practices For Maintaining The Electrical Components Of A Metal Lathe Controller Board To Prevent Accidents?To keep a metal lathe controller board safe, you should check it often. First, make sure to unplug the machine before cleaning. Use a soft cloth to wipe off dust and dirt. Always look for loose wires or broken parts. If something seems wrong, ask an adult for help right away.