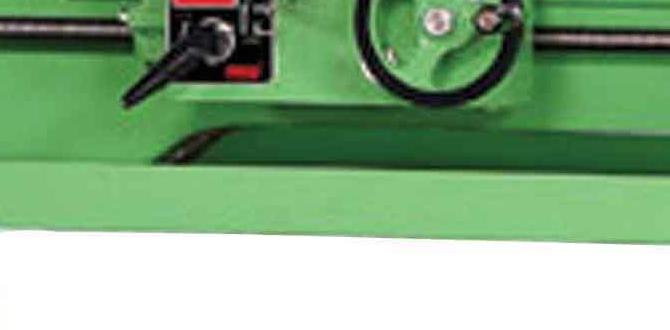

Have you ever wondered how metal parts get their smooth finishes? Many people might not realize that a lathe plays a key role in achieving that perfect look. The lathe machine works hard to shape metals. But its ability to create a great surface finish on metal lathe beds is what really sets it apart.

Picture this: you walk into a workshop and see a shiny metal piece. You might think it looks amazing, but do you know what makes it so special? Much of that sleek look comes from a well-finished lathe bed. It’s like the foundation of a house. Without a strong base, everything else can crumble.

Here’s something surprising: the smoothness of a lathe surface finish can affect not just how things look, but also how well they work. Imagine trying to fit two puzzle pieces together. If one is rough, it won’t fit right. The same goes for metal parts. A good lathe bed ensures everything fits together perfectly.

So, next time you admire a shiny metal piece, think about the lathe surface finish. It’s not just for looks; it’s crucial for function too. Let’s explore how it all works!

Achieving A Perfect Lathe Surface Finish For Metal Lathe Bed

Lathe Surface Finish: Metal Lathe Bed Insights

Achieving a smooth surface finish on a metal lathe bed is crucial for precision machining. Did you know that the finish affects the quality of your final product? A well-finished lathe bed reduces friction and wear, leading to longer tool life. Proper maintenance and regular cleaning help maintain this quality. Understanding the factors that influence surface finish can improve your projects significantly. How can you ensure your lathe bed stays in top shape?Understanding Lathe Surface Finish

Definition and importance of surface finish in metalworking. Key factors affecting surface finish quality.Surface finish is how smooth or rough a metal part looks and feels. It is very important in metalworking. A good finish helps parts fit together better and last longer. It also makes parts look nice. Several key factors affect surface finish quality:

- Cutting speed

- Tool material

- Feed rate

- Coolant use

Each of these factors can change how a metal lathe bed feels. A better finish can lead to stronger and more reliable products. Quality matters!

Why is surface finish so important?

A smooth surface reduces friction, enhances appearance, and improves performance. All these help machines work better and last longer.

Measuring Surface Finish

Common methods and tools used for measurement (e.g., profilometers, gauges). Understanding surface finish parameters (Ra, Rz, etc.).To measure how smooth a metal surface is, special tools are used. Common methods include profilometers and gauges. These tools help look closely at the surface. Understanding terms like Ra (average roughness) and Rz (average height of peaks and valleys) is helpful. Here are some key measurement tools:

- Profilometer: This tool uses a diamond tip to trace the surface.

- Surface Gauge: Simple and manual, it helps check flatness.

Knowing these helps ensure the metal lathe bed is just right for smooth operation.

How do you measure surface finish?

Common methods include tools like profilometers and gauges, which check and analyze the texture of surfaces.Factors Influencing Surface Finish in Metal Lathe Beds

Material properties and their impact on finish. Tool selection and its role in achieving desired surface quality.Choosing the right material for a metal lathe bed is like picking your favorite ice cream flavor—some are just smoother than others. Harder materials can result in a better surface finish. It’s the same story with tool selection. If you pick the right tool, your finish will shine like a new penny! A dull tool can ruin the party, making your piece look like it went through a blender. Check out the table below for a quick summary!

| Factor | Impact on Surface Finish |

|---|---|

| Material Properties | Harder materials give better finishes. |

| Tool Selection | A sharp tool = smooth finish; a dull tool = mess! |

Techniques for Improving Lathe Surface Finish

Best practices for setting up the lathe for optimal finish. Tips for tool maintenance and selection.To get the best surface finish on your lathe, set up your machine correctly. Keep it level and secure. Using the right tools is also key. Choose sharp tools made for your project. Tool maintenance is important; keep them clean and sharpened. This leads to smoother work. Here are some tips:

- Check tool alignment regularly.

- Use cutting oil for a better finish.

- Adjust the feed rate to improve results.

What tools help improve lathe surface finish?

Sharp cutting tools and high-speed steel bits that are well-maintained will help you achieve a better finish.

Troubleshooting Surface Finish Issues

Common problems encountered and their causes. Solutions and adjustments to improve surface quality.Surface finish problems can really get under your skin—like a pesky itch that won’t go away! Common issues include rough textures and strange patterns. Often, they happen due to dull tools or wrong feed rates. Luckily, fixing these problems is usually a piece of cake. For smoother surfaces, try sharpening your tools or adjusting your speeds. Below is a quick reference to help you out:

| Problem | Cause | Solution |

|---|---|---|

| Rough Finish | Dull Tools | Sharpen or replace tools |

| Unusual Patterns | Incorrect Feed Rate | Adjust feed rate to a proper level |

| Chip Build-up | Improper Cooling | Increase coolant flow |

Remember, a little tweak can lead to shiny results. And who doesn’t love shiny things? They make you feel all warm and fuzzy inside! So keep calm, adjust your lathe, and you might just become the master of metal magic.

Case Studies and Examples

Realworld applications showcasing improved surface finishes. Comparative analysis of different approaches and their outcomes.In the world of metalworking, there’s no shortage of exciting stories. For example, a factory improved their lathe surface finish from rough to smooth, making their metal lathe beds shine like new. This change not only looked good but also made their products last longer. Let’s compare their method to another factory’s approach. While one used a traditional technique, the other opted for modern tools. The results? A shiny finish for the first and a dull outcome for the second!

| Factory | Method | Surface Finish Outcome |

|---|---|---|

| Factory A | Modern Tools | Smooth and Shiny |

| Factory B | Traditional Technique | Dull and Rough |

These examples clearly show how picking the right methods can turn a boring metal bed into a superstar!

Future Trends in Lathe Surface Finishing

Innovations in technology affecting surface finish methods. Emerging materials and techniques to watch for in the industry.Exciting changes are happening in lathe surface finishing! New tools and machines are making things smoother and better. Technologies like 3D printing are changing how we make parts. We can also expect new materials like composite metals that are lighter and stronger. These innovations might lead to faster production and higher quality finishes. Imagine a world where parts are ready in no time!

What new technologies are improving surface finishing?

New technologies like robotics and AI are improving how we finish surfaces. These tools speed up work and make it easier to achieve smooth finishes.

Emerging Materials and Techniques

- Composite metals

- 3D printing

- Smart sensors

Conclusion

In conclusion, a lathe surface finish on a metal lathe bed is vital for smooth operation. A good finish reduces friction and wear. To achieve this, you can use proper tools and techniques. Remember, a well-maintained lathe lasts longer and produces better work. For more tips, consider exploring articles on lathe maintenance and operation. Happy turning!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Surface Finish For A Metal Lathe Bed:Sure! A lathe is a machine that shapes metal. The surface finish on a lathe bed is important. It helps the machine run smoothly. A good finish means less friction and better work. You can improve the finish by using sharp tools and the right speed.

Sure! Please ask your question, and I’ll give you a simple answer.

What Are The Key Factors That Influence The Surface Finish Of A Metal Lathe Bed During Manufacturing?The surface finish of a metal lathe bed depends on a few key factors. First, we need to use the right cutting tools. Sharp tools make smoother surfaces. Second, the speed and feed rate matter. If we move too fast or slow, it can affect the finish. Finally, good preparation of the metal helps. Clean and smooth materials lead to better final results.

How Do Different Machining Processes Affect The Surface Finish Quality Of A Lathe Bed?Different machining processes make the surface of a lathe bed smoother or rougher. When you use cutting tools, they can leave marks, which might not feel nice. If you use grinding, it can make the surface really smooth, almost like glass. Sanding can also help, but it may leave some scratches. Each method affects how the lathe bed looks and feels.

What Surface Finish Specifications Are Commonly Required For Precision Metal Lathe Beds, And Why Are They Important?For precision metal lathe beds, we often need a smooth finish, like a mirror. This helps the machine work better and last longer. A smooth surface reduces friction, which means less wear and tear. It also helps make accurate pieces when you cut metal. So, a good finish is super important for the lathe’s performance.

How Can Surface Finish Be Measured, And What Tools Are Typically Used For Assessing The Quality Of A Lathe Bed?We can measure surface finish using special tools. One tool is a roughness tester, which feels the surface to check how smooth it is. We can also use a magnifying glass to look closely at the surface. For a lathe bed, we often use a straight edge or a dial gauge. These help us see if it’s flat and in good shape.

What Techniques Can Be Employed To Improve The Surface Finish Of A Metal Lathe Bed Post-Manufacturing?To make a metal lathe bed smooth, we can use a few techniques. First, we can sand the surface with fine sandpaper. This helps remove bumps and rough areas. Second, we can use polishing compounds to add shine. Lastly, applying a special coating can protect the surface and make it look nice.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Surface Finish For A Metal Lathe Bed:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! A lathe is a machine that shapes metal. The surface finish on a lathe bed is important. It helps the machine run smoothly. A good finish means less friction and better work. You can improve the finish by using sharp tools and the right speed.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please ask your question, and I’ll give you a simple answer.”}},{“@type”: “Question”,”name”: “What Are The Key Factors That Influence The Surface Finish Of A Metal Lathe Bed During Manufacturing?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The surface finish of a metal lathe bed depends on a few key factors. First, we need to use the right cutting tools. Sharp tools make smoother surfaces. Second, the speed and feed rate matter. If we move too fast or slow, it can affect the finish. Finally, good preparation of the metal helps. Clean and smooth materials lead to better final results.”}},{“@type”: “Question”,”name”: “How Do Different Machining Processes Affect The Surface Finish Quality Of A Lathe Bed?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Different machining processes make the surface of a lathe bed smoother or rougher. When you use cutting tools, they can leave marks, which might not feel nice. If you use grinding, it can make the surface really smooth, almost like glass. Sanding can also help, but it may leave some scratches. Each method affects how the lathe bed looks and feels.”}},{“@type”: “Question”,”name”: “What Surface Finish Specifications Are Commonly Required For Precision Metal Lathe Beds, And Why Are They Important?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “For precision metal lathe beds, we often need a smooth finish, like a mirror. This helps the machine work better and last longer. A smooth surface reduces friction, which means less wear and tear. It also helps make accurate pieces when you cut metal. So, a good finish is super important for the lathe’s performance.”}},{“@type”: “Question”,”name”: “How Can Surface Finish Be Measured, And What Tools Are Typically Used For Assessing The Quality Of A Lathe Bed?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “We can measure surface finish using special tools. One tool is a roughness tester, which feels the surface to check how smooth it is. We can also use a magnifying glass to look closely at the surface. For a lathe bed, we often use a straight edge or a dial gauge. These help us see if it’s flat and in good shape.”}},{“@type”: “Question”,”name”: “What Techniques Can Be Employed To Improve The Surface Finish Of A Metal Lathe Bed Post-Manufacturing?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To make a metal lathe bed smooth, we can use a few techniques. First, we can sand the surface with fine sandpaper. This helps remove bumps and rough areas. Second, we can use polishing compounds to add shine. Lastly, applying a special coating can protect the surface and make it look nice.”}}]}