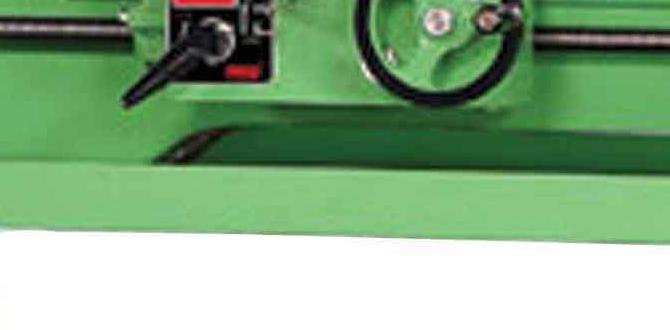

Have you ever wondered how metal objects get that shiny, smooth finish? It often starts with a tool called a lathe. A lathe helps shape metal by removing material. The process can make a big difference in how a product looks and feels.

Imagine walking into a workshop. You see a skilled person at work, creating beautiful items. They use different cutting tools on their lathe. These tools help them achieve a perfect surface finish. But, how do they choose the right tool for each job?

Surface finish is important for many reasons. It affects how well metal parts fit together. It can also determine how long they last. A good surface finish can even make the difference between a product’s success or failure.

Let’s dive deeper into the world of lathe cutting tools. By understanding how they work, you can appreciate the art of metal shaping even more. Are you ready to explore this fascinating topic with us?

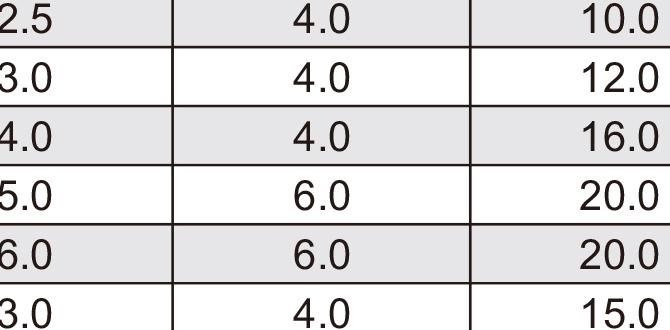

Achieving Perfect Lathe Surface Finish With Metal Lathe Cutting Tools — Introduction In The World Of Machining, Achieving A High-Quality Lathe Surface Finish Is Crucial For The Functionality And Aesthetics Of Metal Components. Lathe Surface Finish Refers To The Texture And Smoothness Of The Finished Product, Which Is Largely Influenced By The Cutting Tools Used During The Machining Process. Metal Lathe Cutting Tools Play A Vital Role In Determining The Final Surface Quality Of Workpieces. In This Article, We Will Explore The Importance Of Surface Finish, Factors Affecting It, And The Types Of Cutting Tools That Can Help Improve Lathe Surface Finishes. Understanding Lathe Surface Finish The Surface Finish Of Lathed Metals Is Usually Measured In Terms Of Roughness, With Common Metrics Being Ra (Average Roughness) And Rz (Average Maximum Height). A Smoother Finish Is Often Desired For Functional Components, As It Can Reduce Friction, Prevent Corrosion, And Improve Appearance. Factors Affecting Lathe Surface Finish Several Factors Contribute To The Quality Of Lathe Surface Finishes, Including: 1. **Cutting Tool Material**: The Type Of Material Used For Cutting Tools, Such As High-Speed Steel (Hss), Carbide, Or Ceramic, Impacts Tool Longevity And Performance. 2. **Cutting Speed**: Higher Cutting Speeds Can Lead To A Better Surface Finish, But Must Be Balanced With The Tool’S Capability And Material Being Machined. 3. **Feed Rate**: The Rate At Which The Tool Moves Through The Material Has A Direct Correlation With The Surface Finish. A Slower Feed Rate Generally Results In A Finer Finish. 4. **Depth Of Cut**: Depth Settings Can Affect Chip Formation And Heat Generation, Which In Turn Impacts Surface Quality. 5. **Tool Geometry**: The Design Of The Cutting Edge, Including Rake Angle And Clearance, Also Influences Cutting Performance And Finish. Types Of Metal Lathe Cutting Tools For Surface Finish To Achieve The Desired Lathe Surface Finish, Choosing The Right Cutting Tools Is Essential. Here Are Some Common Types Of Metal Lathe Cutting Tools: 1. **Indexable Insert Tools**: These Tools Use Replaceable Inserts That Can Be Easily Changed For Different Applications, Making Them Versatile For Achieving Various Surface Finishes. 2. **Hss Tools**: While Not As Durable As Carbide Tools, Hss Tools Can Deliver Excellent Surface Finishes At Lower Speeds And Are Cost-Effective For Small Production Runs. 3. **Carbide Tools**: Solid Carbide Inserts Are Ideal For High-Speed Machining And Can Produce Superior Surface Finishes Due To Their Hardness And Wear Resistance. 4. **Ground Tools**: These Tools Are Precision-Ground To Specific Dimensions And Geometries, Offering Better Control For Creating Fine Finishes. Conclusion Achieving The Perfect Lathe Surface Finish Is A Crucial Aspect Of Metalworking That Significantly Impacts The Performance And Appearance Of Machined Components. By Understanding The Factors That Influence Surface Quality And Selecting Appropriate Metal Lathe Cutting Tools, Machinists Can Produce Parts That Meet Strict Quality Standards. Whether Using Carbide Inserts For High-Speed Operations Or Hss Tools For Cost-Effective Machining, The Right Combination Of Tools And Techniques Will Lead To Improved Surface Finishes And Overall Project Success.

Understanding Lathe Surface Finish with Metal Lathe Cutting Tools

Lathe surface finish is crucial for achieving a high-quality look on metal parts. Using the right metal lathe cutting tools makes all the difference. Have you ever wondered why some parts shine more than others? It’s all about technique and tool selection. A good surface finish reduces friction and enhances the durability of parts. To get that perfect finish, one must consider factors like tool sharpness and feed rates. Every detail matters in creating smooth, precise components.Understanding Lathe Surface Finish

Definition of surface finish in machining. Importance of surface finish in metalworking.Surface finish in machining refers to the texture or smoothness of a material’s surface after shaping. It is like giving your workpiece a nice haircut—nobody wants a messy finish! A good surface finish is crucial in metalworking because it affects how parts fit and work together. Think of it as the difference between a smooth slide or a bumpy ride. Good surface finish can improve durability and reduce wear, making machines run like a well-oiled comedy show!

| Surface Finish Importance | Effects |

|---|---|

| Improved Fit | Joins parts better |

| Corrosion Resistance | Lasts longer |

| Lower Friction | Efficient movement |

Key Factors Affecting Surface Finish

Impact of cutting speed on finish quality. The role of feed rate and depth of cut.Several key factors can shape the quality of a metal’s surface finish. First, cutting speed is crucial. Faster speeds often lead to smoother surfaces. However, too fast can create problems. Next, the feed rate and depth of cut also play important roles. A slower feed rate usually provides a finer finish. Deeper cuts can create rougher surfaces, while shallow cuts tend to smooth them out.

What is the impact of cutting speed on finish quality?

Cutting speed influences the temperature and wear on tools. A good speed can enhance the quality of the surface finish significantly.

Key Factors:

- Proper cutting speed can reduce tool wear.

- Higher speeds can create a smoother surface.

- Too high speeds may cause overheating.

How do feed rate and depth of cut affect finishing?

Both feed rate and depth of cut directly impact the surface. A slower feed results in a finer finish, while a deeper cut usually makes a rougher one.

Guidelines:

- Lower feed rates yield better finishes.

- Shallower cuts often improve smoothness.

Choosing the Right Cutting Tool for Surface Finish

Criteria for selecting cutting tools based on application. The relationship between tool geometry and surface finish quality.Selecting the right cutting tool is key for a smooth finish. Different tools suit different jobs. Consider your project type and desired finish. Tool geometry affects the final quality too. A sharp edge reduces roughness. A flat tool may leave a smoother surface. Factors to think about include:

- Tool material

- Cutting edge shape

- Project material type

Choosing wisely ensures a great result!

What to consider when selecting cutting tools for surface finish?

Focus on job requirements and tool design. Different tasks need different tools. A tool with a proper angle cuts better and gives a finer finish. Always pick tools that match your material for the best results.

Techniques for Achieving Better Surface Finish

Recommended machining techniques and practices. Importance of tool maintenance and sharpening.To create a smooth surface on your lathe work, focus on proper machining techniques. Use sharp tools; dull ones leave ugly marks. Think of your cutting tool like a superhero—sharp tools save the day! Regular sharpening keeps them in top shape, just like a good night’s sleep does for us.

Proper speed and feed rates also help. Too fast? You get a bumpy ride. Too slow? You might get stuck in traffic! Maintaining tools is key; don’t skip this part. Here’s a quick table to remind you:

| Technique | Tip |

|---|---|

| Tool Sharpness | Keep tools sharp for a clean finish. |

| Speed | Adjust speed for smooth cuts. |

| Feed Rate | Find the right feed rate to avoid bumps. |

Good practices lead to beautiful results. So keep those tools happy and shining!

Common Issues and Solutions for Surface Finish Problems

Identification of common defects in surface finish. Strategies for troubleshooting and resolving issues.Surface finish problems can be a real headache. Common defects include roughness, scratches, and chatter marks. These issues make your metal look less shiny than a penny in a wishing well! To fix them, first, check your lathe’s speed and tool bit angle. Are they working well together? Talk about teamwork! Mistakes can happen, but with the right adjustments, you’ll get a polished finish in no time.

| Common Defects | Possible Causes | Solutions |

|---|---|---|

| Rough Surface | Wrong speed or feed rate | Adjust speed or feed rate |

| Scratches | Dirty tool or workpiece | Clean tools and materials |

| Chatter Marks | Improper tool setup | Recheck tool alignment |

Future Trends in Lathe Surface Finish Technology

Innovations in cutting tool materials and coatings. Advancements in CNC technology and their impact on surface finish capabilities.New tools are changing how we make smooth surfaces. Advances in materials and coatings are key. They help tools last longer and cut better. This leads to finer finishes. CNC technology is also improving. It makes machines smarter. This means they can create smoother surfaces faster and with more precision. The future looks bright for lathe surface finishing!

What are the latest trends in lathe surface finish?

The latest trends include new cutting materials, better tool coatings, and smarter CNC technology, which all work together to improve surface finishes.

Key Innovations:

- New cutting tool materials: Harder, more durable materials last longer.

- Advanced coatings: Special coatings reduce friction and wear.

- Smart CNC machines: They improve speed and precision.

Conclusion

In summary, lathe surface finish is important for smooth and strong metal parts. We learned that using the right cutting tools can improve this finish. You should practice using different tools to see what works best. Exploring more resources or tutorials can help you understand and master these techniques. Get started with your lathe projects today!FAQs

Sure! Here Are Five Questions Related To Lathe Surface Finish And Metal Lathe Cutting Tools:Sure! Here are five questions related to lathe surface finish and cutting tools. 1. What is a lathe? A lathe is a tool that spins metal to shape it. 2. What is surface finish? Surface finish is how smooth or rough a metal is after working on it. 3. Why is surface finish important? A good surface finish makes products last longer and feel nice. 4. What is a cutting tool? A cutting tool is used to slice or shape metal on the lathe. 5. Can you use different tools for different finishes? Yes! Different tools can give unique finishes on the metal surface.

Sure! Please provide me with the question you’d like me to answer.

What Factors Influence The Surface Finish Quality When Using A Metal Lathe?When using a metal lathe, the surface finish quality depends on a few key things. First, the speed of the lathe matters. If you go too fast, the surface might be rough. Second, using a sharp cutting tool helps create a smoother finish. Lastly, the way you feed the material into the lathe also affects how it looks. All these factors work together to give you a nice finish on your metal piece.

How Do Different Cutting Tool Materials (E.G., Carbide, High-Speed Steel) Affect The Surface Finish On Lathe-Turned Parts?Different cutting tools can make your project look better or worse. For example, carbide tools are really hard and can make a smooth finish. High-speed steel tools are good too, but they wear out faster. When tools wear down, they can leave rough spots on your project. So, choosing the right tool helps make your work shiny and nice!

What Are The Best Practices For Selecting Cutting Speeds And Feeds To Achieve Optimal Surface Finish On A Lathe?To get a smooth surface when using a lathe, choose the right cutting speed and feed rate. Start with a slower speed and a small feed rate for better finishes. You can increase the speed slowly until you find the best fit. Always check your work to make sure it looks good. Clean the tools regularly to keep them sharp!

How Can Tool Geometry And Design Impact The Surface Finish In Lathe Operations?The shape and design of the tool we use on the lathe matter a lot. A sharper tool can cut better and make smooth surfaces. If the tool is dull or has a weird shape, it might leave rough spots. So, choosing the right tool helps us get a nice finish on the object we’re working on.

What Post-Processing Methods Can Be Employed To Improve The Surface Finish Of Parts Machined On A Lathe?To make lathe-made parts smoother, we can use a few methods. First, we can sand the surface with fine sandpaper. This helps remove any rough spots. Next, you might use a process called polishing, which makes the surface shiny and even smoother. Lastly, some people like to coat the part with a clear finish to protect it and add shine.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Questions Related To Lathe Surface Finish And Metal Lathe Cutting Tools:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are five questions related to lathe surface finish and cutting tools. 1. What is a lathe? A lathe is a tool that spins metal to shape it. 2. What is surface finish? Surface finish is how smooth or rough a metal is after working on it. 3. Why is surface finish important? A good surface finish makes products last longer and feel nice. 4. What is a cutting tool? A cutting tool is used to slice or shape metal on the lathe. 5. Can you use different tools for different finishes? Yes! Different tools can give unique finishes on the metal surface.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide me with the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Factors Influence The Surface Finish Quality When Using A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using a metal lathe, the surface finish quality depends on a few key things. First, the speed of the lathe matters. If you go too fast, the surface might be rough. Second, using a sharp cutting tool helps create a smoother finish. Lastly, the way you feed the material into the lathe also affects how it looks. All these factors work together to give you a nice finish on your metal piece.”}},{“@type”: “Question”,”name”: “How Do Different Cutting Tool Materials (E.G., Carbide, High-Speed Steel) Affect The Surface Finish On Lathe-Turned Parts?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Different cutting tools can make your project look better or worse. For example, carbide tools are really hard and can make a smooth finish. High-speed steel tools are good too, but they wear out faster. When tools wear down, they can leave rough spots on your project. So, choosing the right tool helps make your work shiny and nice!”}},{“@type”: “Question”,”name”: “What Are The Best Practices For Selecting Cutting Speeds And Feeds To Achieve Optimal Surface Finish On A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To get a smooth surface when using a lathe, choose the right cutting speed and feed rate. Start with a slower speed and a small feed rate for better finishes. You can increase the speed slowly until you find the best fit. Always check your work to make sure it looks good. Clean the tools regularly to keep them sharp!”}},{“@type”: “Question”,”name”: “How Can Tool Geometry And Design Impact The Surface Finish In Lathe Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The shape and design of the tool we use on the lathe matter a lot. A sharper tool can cut better and make smooth surfaces. If the tool is dull or has a weird shape, it might leave rough spots. So, choosing the right tool helps us get a nice finish on the object we’re working on.”}},{“@type”: “Question”,”name”: “What Post-Processing Methods Can Be Employed To Improve The Surface Finish Of Parts Machined On A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To make lathe-made parts smoother, we can use a few methods. First, we can sand the surface with fine sandpaper. This helps remove any rough spots. Next, you might use a process called polishing, which makes the surface shiny and even smoother. Lastly, some people like to coat the part with a clear finish to protect it and add shine.”}}]}