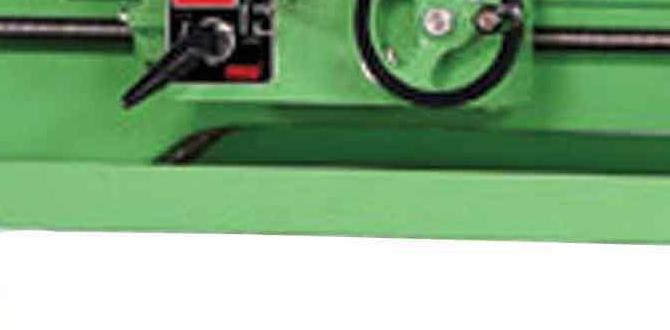

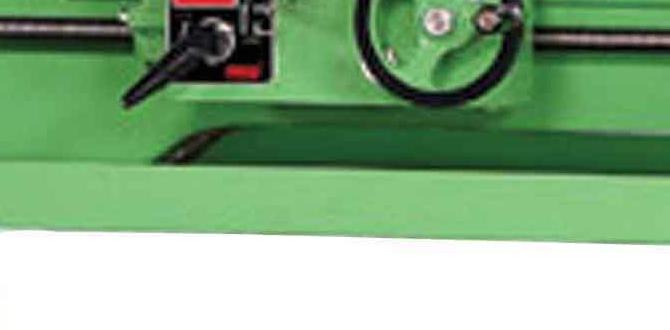

Have you ever wondered how metal can be shaped so smoothly and precisely? Tools like the lathe make it possible! A lathe is a machine that spins metal. This allows for making curved shapes or flat surfaces. But what truly makes the difference in quality is the surface finish. A good finish can change everything.

When it comes to using a metal lathe, the power feed is a game changer. It gives the lathe more strength and control while working. Imagine carving a smooth piece of wood instead of struggling with a dull knife. That’s what power feed does for metalworking. It allows for easy and smooth cuts. This means better surface finishes on your projects.

Did you know that the finish of a metal piece can affect its performance? A shiny, smooth finish not only looks nice but can also help prevent wear and tear. So, if you’re eager to learn about how to achieve the best lathe surface finish, you’re in the right place!

Lathe Surface Finish: Metal Lathe Power Feed Techniques

Lathe Surface Finish: Metal Lathe Power Feed

Lathe surface finish matters for creating smooth metal parts. A good finish improves both appearance and performance. Using a power feed on your metal lathe helps achieve better results. It ensures consistent cutting pressure while you work. Did you know that a finer surface can actually reduce friction? This means your parts last longer. So, next time you use a lathe, consider how power feed impacts your finish!Understanding Lathe Surface Finish

Definition and importance of surface finish in machining. Common surface finish measurement and classification methods.A smooth surface is like the icing on a cake—it makes everything better! In machining, surface finish is how smooth or rough a metal piece is after you’re done shaping it. A good finish matters because it can impact how well parts fit together and their durability. Now, how do we measure this slickness? There are several ways, like Ra (arithmetic average roughness) and Rz (average maximum height). Each method gives different insights into how shiny (or not) things turn out!

| Measurement Method | Description |

|---|---|

| Ra | Average height of surface roughness. |

| Rz | Average maximum height of peaks and valleys. |

Factors Influencing Surface Finish in Metal Lathes

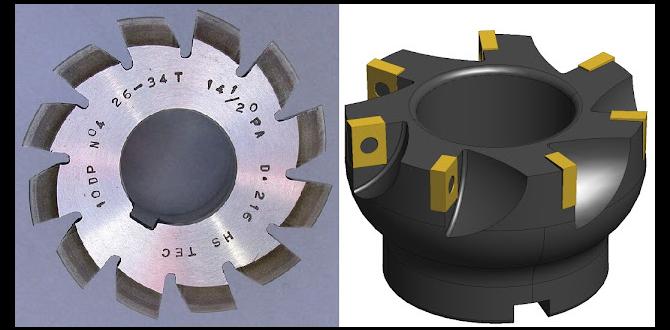

Tool material and geometry considerations. Cutting speed and feed rate impacts.Several factors affect the surface finish when using a metal lathe. The tool material is important. Harder materials make cleaner cuts. The shape of the tool, or its geometry, also matters. A sharp edge produces a smoother finish. Cutting speed plays a role, too. Faster speeds can lead to better results, while slow speeds may cause roughness. Lastly, the feed rate must be balanced. Feeding too fast can ruin the surface quality.

What affects the surface finish in metal lathes?

Three key factors include tool material, cutting speed, and feed rate. The right balance helps in achieving a smooth finish.

Key Factors:

- Tool Material: Harder tools create better finishes.

- Tool Geometry: Sharper tools work best.

- Cutting Speed: Higher speeds usually yield finer finishes.

- Feed Rate: A proper rate prevents roughness.

How Power Feed Enhances Surface Finish

Reduction of tool wear and consistent cut. Improved material removal rates and efficiency.Power feed is like a magic button for metal lathe users. It helps to reduce tool wear by ensuring that the cutting tool moves evenly, which leads to fewer trips to the tool shop! With consistent cuts, your surface finish stays smooth, just like butter on toast. Plus, with improved material removal rates, you can finish your projects faster than a cheetah on roller skates. Efficiency? You’ll feel like a machining superstar!

| Benefit | Impact |

|---|---|

| Reduction of Tool Wear | Longer tool life |

| Consistent Cut | Smoother surfaces |

| Improved Material Removal Rates | Faster work completion |

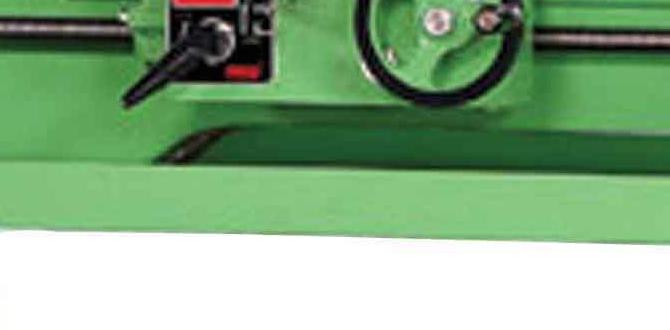

Setting Up Power Feed for Optimal Results

Stepbystep guide to configuring power feed settings. Common mistakes to avoid when using power feed.First, make sure you understand how the power feed works. Start by setting your speed and direction according to your project. Use the controls wisely. Too fast can lead to *oops* moments! Next, check that everything is aligned properly. A little misalignment can cause big problems. Avoid common mistakes like not checking for chips. They love to sneak into gears!

| Common Mistakes | Solution |

|---|---|

| Wrong speed settings | Double-check before starting! |

| Ignoring maintenance | Clean your machine regularly. |

| Misaligned parts | Always align before using. |

Remember, a good setup means a smooth finish! With practice, you’ll be feeding like a pro!

Comparing Manual vs. Power Feed for Surface Finish

Advantages of power feed over manual operation. Scenarios when manual feed may be preferred.Power feed is like a cozy car seat, gently easing you into your task. It provides better surface finishes by moving smoothly, while making your hands less tired. This means you can focus on other important things, like perfecting your coffee break! However, there are times for manual feed too, like when precision is key. Sometimes it feels like being a carving artist, getting every detail just right. Here’s a quick comparison:

| Feature | Power Feed | Manual Feed |

|---|---|---|

| Surface Finish | Excellent | Good |

| Ease of Use | Very Easy | Requires Skill |

| Control | Less Control | High Control |

Each method has its place. Choose smartly and enjoy your lathe journey!

Maintaining Your Lathe for Improved Surface Finish

Routine maintenance tips for keeping lathe components in top shape. Adjustments to make for optimal power feed performance.Taking care of your lathe is like giving it a daily spa treatment. Regular checks keep all parts happy and working great. Clean the bed and lubricate moving parts to ensure they glide like a ballerina on ice. Adjust the power feed for a smoother operation—just like tuning your favorite guitar. Remember, a well-maintained lathe will give you perfect surface finishes that could make even a mirror jealous!

| Routine Maintenance Tips | Adjustments for Power Feed |

|---|---|

| Clean components weekly | Calibrate feed speed regularly |

| Lubricate moving parts | Check feed direction |

| Inspect belts and pulleys | Adjust tension for efficiency |

Case Studies: Successful Applications of Power Feed

Example scenarios showcasing improved surface finish. Testimonials from machinists on power feed effectiveness.Power feed improves how metal lathe machines work. Many machinists have noticed better surface finishes. Here are some examples:

- One machinist reported a 50% increase in quality when using power feed.

- Another shared that the finish on the metal was smoother and more precise than before.

A few machinists said:

- “Power feed makes my job easier and faster!”

- “I love the results. It’s like magic!”

These stories show how power feed helps create great surface finishes.

How does power feed improve surface finish?

Power feed allows for smoother machine movement, which leads to better surface finish on metal parts.

Future Trends in Lathe Technologies

Emerging technologies impacting lathe performance. Predictions for advancements in surface finish capabilities.New technologies are changing how lathes work. The future holds exciting possibilities. Smart machines, called smart lathes, can adjust speed on their own. This helps to create a better surface finish. Predictive software will also help operators plan better.

Here are a few trends to watch:

- Automation will make lathes faster.

- New materials can improve durability.

- Advanced sensors will track performance in real-time.

Overall, these advancements will keep improving lathe performance and surface quality. Expect smoother and sharper finishes in the years ahead!

How will technology improve lathe performance?

Technology will make lathes faster and smarter with automation and improved materials. These changes will lead to better surface finishes and efficiency, making work easier for operators.

Conclusion

In conclusion, using a lathe with a power feed improves surface finish on metal projects. It helps you achieve smoother and more precise results. Remember to adjust your speed and feed rates for the best outcome. We encourage you to practice these techniques and explore more resources on lathe operations. Start machining and see the difference for yourself!FAQs

Here Are Five Related Questions On The Topic Of Lathe Surface Finish And Metal Lathe Power Feed:Sure! A lathe is a tool that helps shape metal or wood. It spins the material while a sharp tool cuts it. This helps make smooth surfaces. Using a power feed means the machine moves automatically, making it easier for us. A good surface finish makes the project look nice and work better!

Sure! Please ask your question, and I’ll be happy to help you.

What Are The Key Factors That Influence The Surface Finish Achieved During Lathe Machining?The surface finish on a lathe comes from a few important factors. First, the type of tool we use can change how smooth the surface is. Second, how fast the lathe spins and how quickly we move the tool plays a role too. Lastly, the material we’re working on can affect the final look. Taking care of these factors helps us get a better finish!

How Does The Power Feed Mechanism Affect The Quality Of The Surface Finish On Machined Parts?The power feed mechanism helps control how fast the machine moves the cutting tool. When it moves smoothly, it makes a better surface finish. A good surface finish means parts look nice and are less rough. If the machine moves too fast or too slow, it can create bumps or scratches. So, using power feed properly helps us create smoother and nicer-looking parts.

What Specific Adjustments Can Be Made To A Lathe’S Power Feed Settings To Improve Surface Finish?To make the surface better on a lathe, you can adjust the power feed speed. If you slow down the feed, the cutting tool can make a smoother surface. Also, use a lighter cut; this means the tool will remove less material at once. Lastly, make sure everything is tight and clean; loose parts can create bumps.

How Do Different Cutting Tools And Insert Geometries Impact The Surface Finish When Using Power Feed On A Lathe?Different cutting tools and shapes can change how smooth a surface is when we use a lathe with power feed. If we use a sharp tool, it cuts better and makes a shiny finish. A tool with a round shape can create a smoother surface than a flat one. Changing the angle of the tool also helps make the surface look nicer. So, the right tool and shape are important for a good finish!

What Finish Standards (E.G., Ra, Rz) Are Typically Desired In Lathe-Machined Components, And How Can They Be Measured?In lathe machines, we often want a smooth surface. Two common finish standards we use are Ra and Rz. Ra measures how rough a surface is, while Rz tells us the height of the bumps. We can measure these with special tools called surface finish testers. These tools check the smoothness and help us make things just right!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Here Are Five Related Questions On The Topic Of Lathe Surface Finish And Metal Lathe Power Feed:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! A lathe is a tool that helps shape metal or wood. It spins the material while a sharp tool cuts it. This helps make smooth surfaces. Using a power feed means the machine moves automatically, making it easier for us. A good surface finish makes the project look nice and work better!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please ask your question, and I’ll be happy to help you.”}},{“@type”: “Question”,”name”: “What Are The Key Factors That Influence The Surface Finish Achieved During Lathe Machining?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The surface finish on a lathe comes from a few important factors. First, the type of tool we use can change how smooth the surface is. Second, how fast the lathe spins and how quickly we move the tool plays a role too. Lastly, the material we’re working on can affect the final look. Taking care of these factors helps us get a better finish!”}},{“@type”: “Question”,”name”: “How Does The Power Feed Mechanism Affect The Quality Of The Surface Finish On Machined Parts?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The power feed mechanism helps control how fast the machine moves the cutting tool. When it moves smoothly, it makes a better surface finish. A good surface finish means parts look nice and are less rough. If the machine moves too fast or too slow, it can create bumps or scratches. So, using power feed properly helps us create smoother and nicer-looking parts.”}},{“@type”: “Question”,”name”: “What Specific Adjustments Can Be Made To A Lathe’S Power Feed Settings To Improve Surface Finish?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To make the surface better on a lathe, you can adjust the power feed speed. If you slow down the feed, the cutting tool can make a smoother surface. Also, use a lighter cut; this means the tool will remove less material at once. Lastly, make sure everything is tight and clean; loose parts can create bumps.”}},{“@type”: “Question”,”name”: “How Do Different Cutting Tools And Insert Geometries Impact The Surface Finish When Using Power Feed On A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Different cutting tools and shapes can change how smooth a surface is when we use a lathe with power feed. If we use a sharp tool, it cuts better and makes a shiny finish. A tool with a round shape can create a smoother surface than a flat one. Changing the angle of the tool also helps make the surface look nicer. So, the right tool and shape are important for a good finish!”}},{“@type”: “Question”,”name”: “What Finish Standards (E.G., Ra, Rz) Are Typically Desired In Lathe-Machined Components, And How Can They Be Measured?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “In lathe machines, we often want a smooth surface. Two common finish standards we use are Ra and Rz. Ra measures how rough a surface is, while Rz tells us the height of the bumps. We can measure these with special tools called surface finish testers. These tools check the smoothness and help us make things just right!”}}]}