Have you ever wondered how to make shiny, smooth metal parts? Many people use a machine called a lathe. This tool shapes metal and gives it a beautiful surface finish. Whether you are a beginner or a pro, lathe surface finish metal lathe projects can be exciting.

Picture this: You come home after a long day. You walk into your workshop, ready to create something amazing. The lathe stands proudly, waiting for your next masterpiece. With the right techniques, you can turn dull metal into a polished work of art!

Did you know that the quality of your surface finish can affect how well your project works? A smooth finish can make things fit together perfectly. It can also make your projects look more professional. Who wouldn’t want that?

In this article, we will explore some fun and easy lathe projects. We will also share helpful tips on how to achieve the best surface finish. Get ready to dive into the world of metal shaping and discover the magic of a lathe!

Achieving Perfect Lathe Surface Finish For Metal Lathe Projects

Lathe Surface Finish and Metal Lathe Projects

Discover how to achieve a perfect surface finish in your metal lathe projects. A smooth finish makes your work look professional. Did you know that the right tools and techniques can greatly improve results? Using a lathe, you can create everything from intricate parts to simple shapes. Experiment with settings like feed rate and cutting speed. Not only will your projects shine, but you’ll also gain valuable skills for future creations. It’s time to unleash your inner craftsman!Understanding Lathe Surface Finish

Definition and importance of surface finish in metalworking. Common surface finish terms and grades.Surface finish is how smooth or rough a metal surface is after working on it. It is important because it affects how the metal part works and looks. A good finish can reduce friction and wear. There are many terms used to describe surface finishes, including:

- Roughness: Small peaks and valleys on the surface.

- Finish Grade: A scale showing the quality of the finish.

- Surface Texture: The pattern on the surface, which can be shiny or dull.

A proper lathe surface finish can make a big difference in metal lathe projects. Without it, parts may not fit or work well.

What is the difference between smooth and rough surface finishes?

Smooth surface finishes are sleek and have low friction. Rough finishes have texture, which can enhance grip but may cause more wear.Factors Affecting Surface Finish in Lathe Work

Tool material and geometry considerations. Impact of cutting speed and feed rate. Role of coolant and lubrication.Several factors can change how smooth a metal piece feels after using a lathe. First, the tool material and its shape affect the cut. A sharp tool works best. Next is the cutting speed and feed rate. Faster speeds usually yield better finishes. Lastly, using coolants and lubrication helps reduce heat and friction, resulting in a finer finish. All these factors work together to create a better surface on your project.

What are some key factors that affect lathe surface finish?

Key factors include tool material, cutting speed, feed rate, and coolant use. These elements are crucial for creating a smooth surface in lathe work.

Key Factors:

- Tool Material and Shape

- Cutting Speed

- Feed Rate

- Coolants and Lubrication

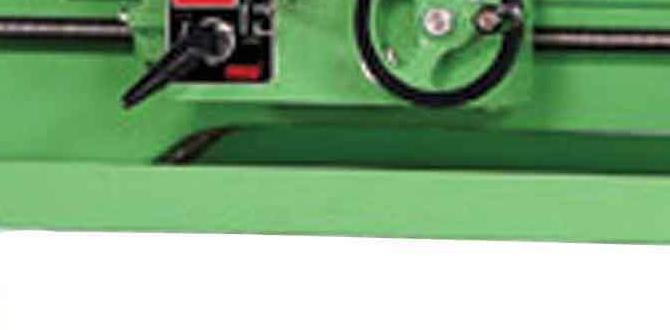

Selecting the Right Lathe for Your Projects

Comparison of different types of lathes for surface finish. Key features to look for in a precision lathe.Choosing the best lathe for your projects is important for a great surface finish. Different lathes can serve different needs. Here are some types to consider:

- Wood Lathes: Great for shaping wood. They give a smooth finish but may not work with metal.

- Metal Lathes: Perfect for metal work. They are sturdy and precise, making metal surfaces shine.

- CNC Lathes: Automated and very accurate. They bring modern tech to your projects.

Look for these key features in a precision lathe:

- Power: A strong motor gives better cutting speed.

- Bed Length: Longer beds allow for bigger projects.

- Ease of Use: Controls should be simple and clear.

Picking the right lathe makes a big difference. Smooth finishes are possible when you set things up right.

What should I consider when choosing a lathe?

Think about your project needs, material type, and your experience level. Choose a lathe that matches your skills to ensure great results.

Techniques for Achieving a Superior Surface Finish

Recommended cutting tools and their application. Best practices for tool sharpening and maintenance.Choosing the right cutting tools is key for a smooth surface finish. High-speed steel and carbide tools are favorites among many. These tools can cut through metal easily and last longer. For sharpening tools, use a fine sharpening stone. Keep tools clean and dry to avoid rust. Regular maintenance helps keep them in top shape. A sharp tool cuts better, which leads to a finer finish. Remember to check your tools often!

What cutting tools should I use for metal lathe projects?

Use high-speed steel and carbide tools for best results. They provide an excellent finish and are durable.

Best practices for tool sharpening and maintenance:

- Use a fine sharpening stone.

- Clean tools after each use.

- Store tools in a dry place.

- Regularly check for wear and tear.

Surface Finish Measurement and Quality Control

Methods for measuring surface finish accurately. Importance of quality control in lathe projects.Measuring surface finish is as important as frosting on a cake. There are several methods to check how smooth the surface is. Common techniques include using a profilometer or roughness gauge. These tools help determine how rough or smooth a surface is. Quality control is key in lathe projects. Good quality helps parts fit together better, and nobody enjoys a wobbly wheel! Regular checks keep your work top-notch and ready for anything.

| Method | Description |

|---|---|

| Profilometer | A tool that measures surface texture. |

| Roughness Gauge | Checks the smoothness using a small tool. |

Did you know quality control can reduce errors by up to 30%? That’s a lot of saved time and effort. So, keep those surfaces smooth and check them often!

Common Mistakes That Ruin Surface Finish

Identification of frequent errors made by beginners. Tips for troubleshooting and correcting surface finish issues.Many beginners face common mistakes that harm their surface finish. Poor tool selection and blunt cutting edges can ruin the final look. Inappropriate speeds and feeds also lead to rough results. Here are some tips to improve your work:

- Use sharp tools for a smoother cut.

- Select the right speed for your material.

- Keep the lathe clean and well-maintained.

- Take lighter cuts for a better finish.

Fixing these issues can lead to stunning projects and save time! Remember, practice makes perfect!

What are some common mistakes with surface finish?

Common mistakes include using dull tools, wrong speeds, and not cleaning the lathe. These can all make your work look bad.

How can I improve my surface finish?

Improve by choosing sharp tools, adjusting speeds, and keeping everything clean.

Conclusion

In summary, achieving a good surface finish on lathe projects is important for both appearance and function. You can improve your skills through practice and by learning different techniques. Experimenting with various materials will also help. Consider exploring videos or tutorials online to deepen your understanding. With each project, you’ll gain confidence and skill in using your lathe!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Surface Finish And Metal Lathe Projects:Sure! Here are five questions about lathe surface finish and metal lathe projects: 1. What is a lathe? A lathe is a tool that spins metal to shape it. You can make things like parts or pieces. 2. Why is surface finish important? A smooth surface finish is important because it makes the metal look nice and fit well with other parts. 3. How do we improve surface finish? We can improve the surface finish by using different tools and techniques to make it smooth. 4. Can you make cool projects with a lathe? Yes! You can make fun projects like toys, tools, or decorations using a lathe. 5. What should you remember for safety? Always wear safety goggles and follow rules when using a lathe to stay safe.

Sure! Please provide the question you want me to answer.

What Factors Influence The Surface Finish Quality When Machining With A Metal Lathe?When you use a metal lathe, several things affect how smooth the surface turns out. First, the speed of the lathe matters; going too fast can make it rough. Next, the type of cutting tool you use is important; sharp tools create better finishes. The pressure you put on the tool also affects the quality; too much pressure can cause damage. Lastly, the material you’re working with plays a role; some metals are smoother than others when cut.

How Can Different Cutting Tools And Tool Materials Affect The Surface Finish Of Lathe-Project Components?Different cutting tools and tool materials can change how smooth or rough a piece of work looks. If you use a sharp tool, it can make a nice, smooth finish. A dull tool can cause scratches and make the surface bumpy. Also, some materials, like certain metals, cut better than others. So, choosing the right tool is important for the best look!

What Are Some Common Techniques Or Processes Used To Improve Surface Finish After Turning On A Lathe?To make a smooth surface after turning on a lathe, you can use a few tricks. First, you can change the cutting tool to a sharp one. This helps cut cleanly. You can also adjust the speed of the lathe; faster speeds often give smoother results. Lastly, some people sand or polish the surface after turning to make it shiny and smooth.

How Do Spindle Speed And Feed Rate Settings Impact The Final Surface Finish Of A Machined Part?Spindle speed is how fast the tool spins, and feed rate is how quickly the tool moves over the part. If you set the spindle speed too high, it can create rough surfaces. A slower feed rate usually leads to smoother finishes, while a faster feed rate can make things rougher. Choosing the right settings helps make the part look nice and feel smooth.

What Are The Best Practices For Selecting Materials And Tooling In Order To Achieve Optimal Surface Finishes On Metal Lathe Projects?To get a smooth finish on metal lathe projects, choose the right materials and tools. Use high-quality metal for better results. Select sharp tools that fit your project size. Keep your lathe clean and well-oiled. Finally, adjust the speed correctly for the best surface finish.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Surface Finish And Metal Lathe Projects:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are five questions about lathe surface finish and metal lathe projects: 1. What is a lathe? A lathe is a tool that spins metal to shape it. You can make things like parts or pieces. 2. Why is surface finish important? A smooth surface finish is important because it makes the metal look nice and fit well with other parts. 3. How do we improve surface finish? We can improve the surface finish by using different tools and techniques to make it smooth. 4. Can you make cool projects with a lathe? Yes! You can make fun projects like toys, tools, or decorations using a lathe. 5. What should you remember for safety? Always wear safety goggles and follow rules when using a lathe to stay safe.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you want me to answer.”}},{“@type”: “Question”,”name”: “What Factors Influence The Surface Finish Quality When Machining With A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When you use a metal lathe, several things affect how smooth the surface turns out. First, the speed of the lathe matters; going too fast can make it rough. Next, the type of cutting tool you use is important; sharp tools create better finishes. The pressure you put on the tool also affects the quality; too much pressure can cause damage. Lastly, the material you’re working with plays a role; some metals are smoother than others when cut.”}},{“@type”: “Question”,”name”: “How Can Different Cutting Tools And Tool Materials Affect The Surface Finish Of Lathe-Project Components?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Different cutting tools and tool materials can change how smooth or rough a piece of work looks. If you use a sharp tool, it can make a nice, smooth finish. A dull tool can cause scratches and make the surface bumpy. Also, some materials, like certain metals, cut better than others. So, choosing the right tool is important for the best look!”}},{“@type”: “Question”,”name”: “What Are Some Common Techniques Or Processes Used To Improve Surface Finish After Turning On A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To make a smooth surface after turning on a lathe, you can use a few tricks. First, you can change the cutting tool to a sharp one. This helps cut cleanly. You can also adjust the speed of the lathe; faster speeds often give smoother results. Lastly, some people sand or polish the surface after turning to make it shiny and smooth.”}},{“@type”: “Question”,”name”: “How Do Spindle Speed And Feed Rate Settings Impact The Final Surface Finish Of A Machined Part?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Spindle speed is how fast the tool spins, and feed rate is how quickly the tool moves over the part. If you set the spindle speed too high, it can create rough surfaces. A slower feed rate usually leads to smoother finishes, while a faster feed rate can make things rougher. Choosing the right settings helps make the part look nice and feel smooth.”}},{“@type”: “Question”,”name”: “What Are The Best Practices For Selecting Materials And Tooling In Order To Achieve Optimal Surface Finishes On Metal Lathe Projects?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To get a smooth finish on metal lathe projects, choose the right materials and tools. Use high-quality metal for better results. Select sharp tools that fit your project size. Keep your lathe clean and well-oiled. Finally, adjust the speed correctly for the best surface finish.”}}]}