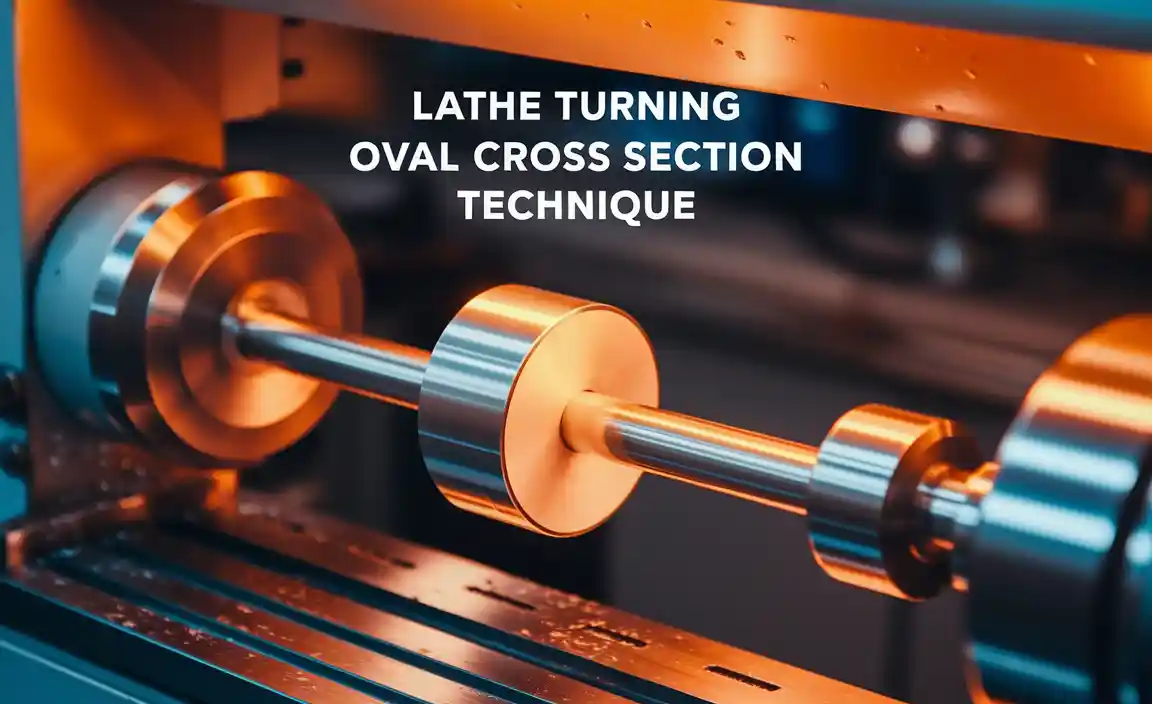

Have you ever wondered how to create smooth, shiny metal parts? The secret often lies in using a lathe. A lathe can shape metal, wood, or plastic into smooth forms. But did you know that the surface finish is just as important as the shape? A great finish can make your work look professional.

Many hobbyists and professionals enjoy using a metal lathe. Yet, they might overlook an important detail: the lathe stand. A sturdy and well-designed lathe stand helps support the machine while allowing precision and stability. Imagine trying to work with a wobbly lathe. It would be a mess! But with the right stand, you can ensure quality results.

Let’s explore the world of lathe surface finish and the impact of a solid lathe stand. By understanding these two elements, you can take your projects to the next level. Ready to dive in?

Achieving A Smooth Lathe Surface Finish With A Metal Lathe Stand

Understanding Lathe Surface Finish and Metal Lathe Stands

The lathe surface finish greatly impacts the quality of your project. A smooth finish enhances aesthetics and function. Did you know that the type of metal lathe stand affects stability and vibration? A sturdy base promotes better finishes. Proper alignment also plays a crucial role. Imagine trying to paint a wall with a wobbly ladder; the result wouldn’t be great! Choosing the right lathe surface finish and a solid stand can elevate your craftsmanship to new heights.Understanding Lathe Surface Finish

Definition of lathe surface finish. Importance of surface finish in machining operations.Lathe surface finish is how smooth or rough a metal piece is after machining. Think of it as the fancy icing on a cake. Why does it matter? A good surface finish helps parts fit together better and last longer. Plus, who wants a metal piece that feels like a porcupine? In fact, a famous saying goes, “Good finish is the key to a happy part!” Below is a quick look at the importance:

| Aspect | Importance |

|---|---|

| Fit | Ensures smooth assembly of parts |

| Durability | Reduces wear and tear over time |

| Aesthetics | Makes the product look polished |

Factors Affecting Lathe Surface Finish

Role of tool material and geometry. Influence of cutting speed and feed rate.Many things affect how smooth a surface will be when you use a lathe. First, the material and shape of the tool are key. Some materials cut better than others. Then, we have the speed of cutting and the feed rate. If you go too fast, it can leave rough edges. If you go too slow, it might not cut well. So, finding the right balance is like making the perfect sandwich—too much of one thing can make it messy!

| Factor | Effect |

|---|---|

| Tool Material | Affects durability and sharpness |

| Geometry | Influences cutting angles and shapes |

| Cutting Speed | Higher speeds can cause roughness |

| Feed Rate | Too high may create roughness |

Every part plays a role in the final outcome, and knowing how to adjust them means you will have a shiny, smooth finish. Just remember, practice makes perfect, and soon you’ll be as smooth as butter!

Choosing the Right Metal Lathe Stand

Key features to look for in a lathe stand. Material options and their impact on stability.Choosing the perfect metal lathe stand is key for a smooth workshop experience. First off, look for solid features. A good stand should be sturdy, as a shaky one might turn your precision work into a wobbly mess. Next, consider materials. Steel or cast iron are great for stability, while lighter materials may not hold up well under pressure. Remember, nobody wants their lathe to do the cha-cha dance while working!

| Material | Stability | Weight Capacity |

|---|---|---|

| Steel | High | Excellent |

| Cast Iron | Very High | Fantastic |

| Aluminum | Moderate | Good for light tasks |

So, choose wisely, and your metal lathe stand will support you well—like a trusty sidekick on your machining adventures!

Maintenance Tips for a Quality Surface Finish

Regular checks and adjustments for accuracy. Cleaning and lubrication practices.To keep your lathe in top shape, you need to check its parts regularly. This includes making small adjustments to ensure everything runs smoothly. Remember, a small tweak can save you from big problems later! Next, cleaning is crucial; dirt loves to build up, and we don’t want that! Lubrication helps keep things sliding nicely. Think of it like giving your lathe a relaxing spa day.

| Maintenance Task | Frequency | Tip |

|---|---|---|

| Check Alignment | Weekly | Measure twice, adjust once! |

| Clean Components | Every use | No one likes a dirty lathe! |

| Lubricate Moving Parts | After every few uses | Invite the oil to the party! |

Following these tips can help ensure a quality surface finish on your projects. Remember, happy lathes make happy users!

Types of Metal Lathe Stands and Their Benefits

Fixed stands vs. adjustable stands. Portable options for small workshops.Choosing a metal lathe stand can feel like picking ice cream flavors—so many options! You can go for fixed stands, which stay put and are super sturdy. They’re great for bigger machines. Or, you might like adjustable stands that can change heights. This is like adjusting your chair for a good view of a game! If you have a small workshop, portable stands make moving around easier, almost like packing your toys for a fun trip!

| Type of Stand | Benefits |

|---|---|

| Fixed Stand | Very sturdy for big machines |

| Adjustable Stand | Can change height easily |

| Portable Stand | Great for small spaces and easy to move |

Common Mistakes to Avoid for Better Surface Finish

Overlooking setup precision. Ignoring tool wear and maintenance. “`htmlMany people forget to check their setup precision before starting. This can lead to a rough surface finish. Remember, “measure twice, cut once,” is the motto for a reason! Another common slip is ignoring tool wear. A dull tool can ruin your masterpiece faster than a cat can knock over a vase. Regular maintenance keeps your tools sharp and your surfaces shiny!

| Common Mistakes | Effects |

|---|---|

| Overlooking setup precision | Rough surface finish |

| Ignoring tool wear | Dull tools lead to poor finish |

Upgrading Your Lathe for Improved Surface Finish

Incorporating advanced technology and tools. Assessing the need for additional attachments.Improving your lathe’s surface finish can be fun and rewarding. Using advanced technology and tools can make a big difference. Upgrading your lathe might include digital readouts or better cutting tools. Also, consider adding attachments like:

- Tool holders for better precision

- Power feeds for smoother motion

- Faceplates for larger projects

These upgrades can help your lathe work better and produce smoother finishes.

How can technology improve my lathe?

Technology can provide better control and precision, leading to smoother surfaces.

Real-Life Applications of Improved Surface Finish

Importance in various industries (automotive, aerospace, etc.). Case studies showcasing the impact of quality finishes.Having a smooth surface finish is vital for many industries. In automotive and aerospace, parts with better finishes can boost performance and safety. Studies show that a well-finished part can reduce friction, leading to fewer breakdowns and longer life. For example, a manufacturers’ report revealed that they decreased repair costs by 30% just by improving surface quality. Less friction means more fun on the road, right? Who wouldn’t want their car to glide like a penguin on ice!

| Industry | Impact of Improved Surface Finish |

|---|---|

| Automotive | Reduced wear, better fuel efficiency |

| Aerospace | Enhanced safety, improved aerodynamics |

Conclusion

In conclusion, a good lathe surface finish is crucial for quality metalwork. It ensures smoother surfaces and better functionality in your projects. Building a sturdy lathe stand helps stabilize your machine, improving your results. We encourage you to explore tips on enhancing your lathe skills and creating a reliable stand. Happy crafting and keep learning!FAQs

Certainly! Here Are Five Questions Related To Lathe Surface Finish And Metal Lathe Stands:Sure! Here are some answers: 1. A lathe is a machine that shapes metal by spinning it. 2. The surface finish is how smooth or rough the metal looks after it’s shaped. 3. You can make the finish nicer by using special tools or sandpaper. 4. Metal lathe stands are stands that hold the lathe up and keep it steady. 5. Using a strong stand helps you work better and keep the lathe safe.

Sure! Please provide the question you want me to answer.

What Factors Influence The Surface Finish Of A Workpiece When Using A Metal Lathe?Many factors can change how smooth a metal piece feels after using a metal lathe. First, the speed of the lathe matters; going too fast or too slow can create bumps. Second, the sharpness of the cutting tool is important; a dull tool can leave rough spots. Lastly, how much pressure you apply while cutting can affect the finish, too. Keeping these in mind helps us make better-looking metal pieces!

How Can Different Cutting Tools And Techniques Affect The Overall Quality Of A Lathe’S Surface Finish?Different cutting tools and techniques can change how smooth or rough a lathe’s surface looks. If you use a sharp tool, it cuts better and leaves a nice finish. But if the tool is dull, it can make the surface rough and bumpy. Also, how fast you move the tool matters; moving too quickly can make a mess. So, choosing the right tool and moving at the right speed helps create a smoother surface.

What Are The Best Practices For Setting Up A Metal Lathe Stand To Enhance Precision And Surface Finish?To set up a metal lathe stand for better precision, start by placing it on a sturdy, level surface. Make sure the lathe is tightly secured to the stand. This helps keep everything stable while you work. You should also check that the tools and materials are organized and easy to reach. Lastly, clean the lathe regularly to keep it running smoothly and improve the finish of your work.

How Does The Material Of The Lathe Stand Impact The Performance And Vibration Dampening Of The Lathe During Machining?The material of the lathe stand can help make the lathe work better. If the stand is heavy and strong, it can reduce vibrations. This means that the machine stays steady and works more smoothly. A stable stand helps us create better and more accurate shapes when we are cutting materials. So, choosing the right material for the stand is very important for good performance.

What Are Common Surface Finish Measurement Techniques Used In Evaluating The Output Of A Metal Lathe?We can use several ways to check how smooth a metal lathe makes a surface. One way is to feel it with our fingers. If it feels rough, we know it needs work. Another way is to use a special tool called a surface roughness tester. This tool measures tiny bumps and flatness on the metal surface. Finally, we can also look at the surface under a microscope to see its details closely.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Certainly! Here Are Five Questions Related To Lathe Surface Finish And Metal Lathe Stands:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are some answers: 1. A lathe is a machine that shapes metal by spinning it. 2. The surface finish is how smooth or rough the metal looks after it’s shaped. 3. You can make the finish nicer by using special tools or sandpaper. 4. Metal lathe stands are stands that hold the lathe up and keep it steady. 5. Using a strong stand helps you work better and keep the lathe safe.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you want me to answer.”}},{“@type”: “Question”,”name”: “What Factors Influence The Surface Finish Of A Workpiece When Using A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Many factors can change how smooth a metal piece feels after using a metal lathe. First, the speed of the lathe matters; going too fast or too slow can create bumps. Second, the sharpness of the cutting tool is important; a dull tool can leave rough spots. Lastly, how much pressure you apply while cutting can affect the finish, too. Keeping these in mind helps us make better-looking metal pieces!”}},{“@type”: “Question”,”name”: “How Can Different Cutting Tools And Techniques Affect The Overall Quality Of A Lathe’S Surface Finish?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Different cutting tools and techniques can change how smooth or rough a lathe’s surface looks. If you use a sharp tool, it cuts better and leaves a nice finish. But if the tool is dull, it can make the surface rough and bumpy. Also, how fast you move the tool matters; moving too quickly can make a mess. So, choosing the right tool and moving at the right speed helps create a smoother surface.”}},{“@type”: “Question”,”name”: “What Are The Best Practices For Setting Up A Metal Lathe Stand To Enhance Precision And Surface Finish?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To set up a metal lathe stand for better precision, start by placing it on a sturdy, level surface. Make sure the lathe is tightly secured to the stand. This helps keep everything stable while you work. You should also check that the tools and materials are organized and easy to reach. Lastly, clean the lathe regularly to keep it running smoothly and improve the finish of your work.”}},{“@type”: “Question”,”name”: “How Does The Material Of The Lathe Stand Impact The Performance And Vibration Dampening Of The Lathe During Machining?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The material of the lathe stand can help make the lathe work better. If the stand is heavy and strong, it can reduce vibrations. This means that the machine stays steady and works more smoothly. A stable stand helps us create better and more accurate shapes when we are cutting materials. So, choosing the right material for the stand is very important for good performance.”}},{“@type”: “Question”,”name”: “What Are Common Surface Finish Measurement Techniques Used In Evaluating The Output Of A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “We can use several ways to check how smooth a metal lathe makes a surface. One way is to feel it with our fingers. If it feels rough, we know it needs work. Another way is to use a special tool called a surface roughness tester. This tool measures tiny bumps and flatness on the metal surface. Finally, we can also look at the surface under a microscope to see its details closely.”}}]}