Have you ever wondered how precision tools shape metal? The lathe is one of those amazing machines. It spins materials around to make smooth and perfect shapes. But here’s the catch: getting every part to line up just right can be tricky. That’s where the lathe tailstock offset method comes in.

This clever technique helps fix misalignments. Imagine trying to balance a pencil on your finger. It’s hard, right? The lathe tailstock offset method is like finding that perfect balance point. It adjusts the tailstock, which holds the other end of the material, so everything turns evenly.

It’s fascinating how such a simple change can lead to better results. Using this method can improve the quality of your work. So, if you’re curious about how to make your lathe projects shine, stick around. You might just learn something amazing!

Understanding The Lathe Tailstock Offset Method Effectively

Lathe Tailstock Offset Method Explained

The lathe tailstock offset method is a handy technique for ensuring precision in your woodworking projects. By adjusting the tailstock, you can align the workpiece properly, helping to achieve smoother cuts. Imagine this: you’re creating a beautiful bowl but notice it wobbles. Using the tailstock offset method, you can fix that wobble easily! This method enhances the accuracy of your work, making it a must-try for any crafting enthusiast. Want to make perfect pieces every time? Give it a shot!What is Lathe Tailstock Offset?

Definition and purpose of the tailstock offset method. Importance of tailstock offset in precision machining.The tailstock offset method is a technique in lathe machining. It helps ensure that parts are shaped accurately. By adjusting the tailstock, workers can fix misalignments in the workpiece. This method plays a key role in precision machining. It enhances the quality of items made in the lathe. With proper offset, parts fit better and work smoothly.

Why is the tailstock offset important?

The tailstock offset is crucial for several reasons:

- Improves accuracy: It ensures parts are shaped correctly.

- Reduces waste: Less material is wasted during machining.

- Increases safety: It minimizes the risk of mistakes.

When to Use Tailstock Offset?

Scenarios that require tailstock adjustments. Benefits of using tailstock offset in different machining tasks.There are times when a lathe needs a little help to shape things just right. For example, if you’re turning a long piece and it wobbles, it’s time to adjust the tailstock. This offset method aligns your work, making cuts smoother and more accurate. Imagine a hot dog rolling off a grill—tailstock adjustments keep it in place!

Using this method offers several perks:

| Scenario | Benefits |

|---|---|

| Long pieces | Improved accuracy |

| Uneven surfaces | Smoother finishes |

| Heavy workpieces | Better stability |

In short, when your lathe feels like it’s dancing, a tailstock offset keeps it grounded and working like a champ!

Step-by-Step Guide to Set Up Tailstock Offset

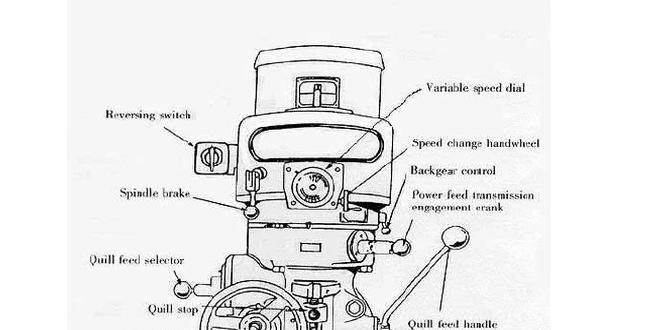

Detailed procedure for adjusting the tailstock on a lathe. Tips for ensuring accuracy during setup.Adjusting the tailstock on a lathe can improve your work’s accuracy. Here’s how to do it:

- Start by loosening the tailstock clamp.

- Move the tailstock until it’s aligned with the spindle.

- Tighten the clamp securely.

- Use a dial gauge to check for accuracy.

- If needed, make small adjustments.

For the best results, be patient. Double-check each step. Keep your workspace clean. Happy turning!

How to ensure accuracy when setting up a tailstock?

Always use a dial indicator for precise adjustments. Keep both the tailstock and spindle clean. Regularly check alignment with each setup. It helps to prevent errors.

Common Mistakes to Avoid with Tailstock Offset

List of frequent errors in tailstock adjustment. Consequences of improper offset settings.Adjusting the tailstock can be tricky! Many folks make common mistakes that can mess things up. Some errors include not securing the tailstock properly, placing it too far from the center, or forgetting to check the alignment. These blunders can lead to wobbly workpieces or uneven surfaces. Imagine trying to balance a lopsided cake; not fun!

| Error | Consequence |

|---|---|

| Improper alignment | Wobbly pieces |

| Loose tailstock | Inaccurate cuts |

| Too much offset | Uneven wear on tools |

Mind those mistakes! They can turn a neat project into a confusing puddle of wood or metal. It’s like trying to follow a recipe without knowing the ingredients—chaos!

Advantages of Using Tailstock Offset Method

Enhanced precision in machining operations. Improved quality of finished products.The tailstock offset method brings great perks to machining! For starters, it boosts precision. By adjusting the tailstock, you help keep everything straight and true, making your parts fit better. Imagine trying to put together a jigsaw puzzle—with misplaced pieces, it’s chaos! This method also enhances the final product’s quality. Smooth finishes and tight tolerances make all the difference.

| Benefit | Impact |

|---|---|

| Enhanced Precision | More accurate cuts and shapes |

| Improved Quality | Smoother and better-finished products |

So, if precision and quality are your game, this method is like having your cake and eating it too—without the calories!

Real-World Applications of Tailstock Offset

Industries that benefit from tailstock offset technique. Case studies demonstrating successful implementations.Many industries use the tailstock offset method successfully. It helps create precise parts, which is essential in manufacturing. Here are a few areas that benefit:

- Aerospace: Ensures accuracy in aircraft components.

- Automotive: Helps in making engine parts that fit perfectly.

- Medical Devices: Produces precise tools for surgeries.

In one case, an aerospace company improved its part accuracy by 30% using this method. This led to safer flying for everyone.

What industries benefit from the tailstock offset method?

The aerospace, automotive, and medical device industries use this technique to improve precision in their products.

Best Practices for Tailstock Maintenance

Maintenance tips to keep tailstock in optimal condition. Importance of regular checks and calibration.To keep the tailstock in great shape, follow essential maintenance tips. Regular checks catch any problems early. It also helps keep your lathe running smoothly. Calibration makes sure everything fits well. Here are some tips:

- Clean regularly to remove dust and debris.

- Check for wear and tear on moving parts.

- Lubricate parts to reduce friction.

These steps ensure the tailstock performs well. Remember, a well-maintained lathe lasts longer and works better!

Why is tailstock maintenance important?

Regular maintenance helps prevent costly repairs and extends your lathe’s lifespan. Keeping everything in shape also ensures accuracy during machining. For example, even a tiny offset can mess up your work!

Conclusion

In summary, the lathe tailstock offset method helps you improve accuracy when drilling or turning. By adjusting the tailstock, you can align your workpiece more effectively. This method prevents errors and saves time. We encourage you to practice it in your projects. For more detailed instructions, check out related guides or videos. Happy machining!FAQs

Sure! Here Are Five Related Questions On The Lathe Tailstock Offset Method:The lathe tailstock offset method helps us make sure our work is straight and even. When we adjust the tailstock, it helps us correct any mistakes. This means better-looking and better-working pieces. Always check if the tailstock is properly aligned before starting. This method makes your projects more successful!

Sure! Please give me the question you want me to answer.

What Is The Purpose Of Tailstock Offset In Lathe Operations, And When Is It Typically Used?Tailstock offset helps you make parts that are not perfectly round. When you want to shape something like a cone, you use it. You adjust the tailstock, which holds the tool, to one side. This lets you create a slanted or angled surface. We use it often when making special shapes on the lathe.

How Do You Calculate The Appropriate Amount Of Tailstock Offset For Correcting Workpiece Alignment?To fix a workpiece that doesn’t sit straight, we can adjust the tailstock. First, measure how much the workpiece is off. You can do this by using a ruler or a caliper to see the gap. Then, move the tailstock closer or farther away based on how much you measured. Finally, check again to see if it’s straight now!

What Are The Potential Effects Of Not Using Tailstock Offset During The Machining Process?If you don’t use a tailstock offset when machining, it can cause problems. The piece you are working on might not be straight. This can lead to mistakes, like making parts that don’t fit together properly. It can also cause extra wear on your tools. In the end, you might waste time and materials.

Can Tailstock Offset Be Used For Both Turning And Drilling Operations On A Lathe? If So, How Does The Method Differ For Each Operation?Yes, you can use tailstock offset for both turning and drilling on a lathe. For drilling, you shift the tailstock to make the hole deeper or at an angle. This helps you reach tricky spots. For turning, you may offset it to make one side rounder. In both cases, adjusting the tailstock helps to create different shapes.

What Are Some Common Adjustments Or Techniques To Ensure That The Tailstock Is Properly Aligned Before Applying The Offset?To make sure the tailstock is lined up right, first check the center point. You can use a ruler to measure from the tailstock to the workpiece. If it’s not even, gently move the tailstock until it is. It helps to tighten screws once you’re happy with the alignment. Always double-check before you start working!