Have you ever thought about how a lathe works? Imagine shaping a piece of wood or metal into something beautiful. But did you know that the right angles matter a lot? Two important angles are clearance and rake. They play a big role in how well a lathe tool performs.

So, what exactly is lathe tool clearance? This angle helps the tool move smoothly without getting stuck. Think of it like having enough space to slide a book out of a crowded shelf. Now, consider the rake angle. This angle helps the tool cut into the material. It’s similar to how a sharp knife slices through butter.

Understanding these angles can make a big difference in your projects. Choosing the right lathe tool clearance and rake angle means better cuts and less effort. Want to learn how they compare? Let’s dive deeper into this fascinating topic!

Lathe Tool Clearance Vs Rake Angle: Understanding Their Differences

Lathe Tool Clearance vs Rake Angle

Clearance angle and rake angle are crucial in lathe tools. Clearance angle helps avoid rubbing against the workpiece, ensuring smoother cuts. Rake angle, on the other hand, affects how the tool engages with the material. Imagine trying to slice through a cake with a thick knife. The sharper the edge, the easier it is! Understanding these angles improves efficiency and the quality of your work. Exploring these concepts can make your machining more effective and enjoyable.The Importance of Tool Clearance Angle

Explanation of what clearance angle is and its role in preventing tool wear. Effects of insufficient clearance on machining performance and part quality.Clearance angle is the space between the tool and the material being cut. It helps prevent tool wear by allowing chips to escape easily. If this angle is too small, the tool may stick, causing wear and damage. This can lower machining performance and harm part quality. Here are some effects of insufficient clearance:

- Increased friction can lead to overheating.

- Chips can clog the tool, reducing efficiency.

- Surface quality may suffer, leading to rough parts.

In summary, using the right clearance angle is key to keeping tools sharp and parts smooth.

What happens with the wrong clearance angle?

It can cause tools to wear out faster and create poor-quality parts. High heat and stress can lead to tool breakage. This is why choosing the correct angle is so crucial.

The Significance of Rake Angle

Definition of rake angle and its influence on cutting edge geometry. Discussion of how rake angle affects cutting forces and chip formation.The rake angle is an important feature in cutting tools. It changes how the cutting edge meets the material. A larger rake angle usually means smoother cuts and less force needed. This helps in forming better chips, which can be as satisfying as watching a magic trick! Think of it like a chef’s knife: a sharper, angled blade cuts more easily than a flat one. Proper rake angles can reduce wear and tear on tools and improve efficiency.

| Rake Angle | Effect on Cutting |

|---|---|

| Positive | Reduces cutting force, creates smoother chips |

| Negative | Increases cutting force, can lead to rough chips |

Clearance Angle vs Rake Angle: Key Differences

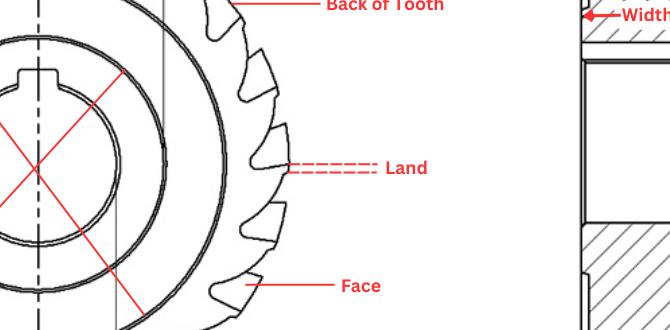

Comparative analysis of clearance angle and rake angle in function and purpose. Visual representation of both angles with diagrams for clarity.Clearance angle and rake angle are important in lathe tools. They change how the tool cuts. Clearance angle helps the tool move freely, avoiding contact with the workpiece. Rake angle helps the tool slice better, improving cutting speed. Here’s a quick look:

- Clearance Angle: Helps prevent sticking.

- Rake Angle: Influences cutting efficiency.

Visual aids can help. Diagrams of both angles show their effects on cutting actions. Understanding these angles can make a big difference in machining!

What is the purpose of clearance angle and rake angle?

The clearance angle allows the tool to move without resistance, while the rake angle improves cutting capacity.

Why are these angles important?

- They improve tool performance.

- They reduce wear and tear.

- They help achieve cleaner cuts.

Optimal Clearance and Rake Angles for Different Materials

Recommended angles for various materials, including metals, plastics, and composites. Effects of material properties on angle selection and machining outcomes.Choosing the right angles is like finding the perfect pizza topping—everyone has their preference! For metals, a rake angle of 6° to 12° works wonders, while plastics enjoy a gentler touch with 10° to 15°. Composites? They like it cozy too, around 5° to 10°. Material properties influence these choices. Softer materials can handle steeper angles, while harder ones need a softer touch for a clean finish. So, aim for those sweet spots to avoid chips and get that smooth cut!

| Material | Recommended Rake Angle |

|---|---|

| Metals | 6° to 12° |

| Plastics | 10° to 15° |

| Composites | 5° to 10° |

Practical Applications and Examples

Realworld scenarios highlighting the impact of clearance and rake angles in machining. Case studies demonstrating improvements in performance with optimal angle settings.Many people use lathe tools in real-life projects. The right clearance and rake angles can change their work. For example, a small factory improved its output by 20%. They learned that better angles made cutting easier. Here are some practical benefits:

- Higher precision in cuts

- Less wear on tools

- Faster production times

These examples show how important angles are in machining. Proper settings lead to success!

What are the benefits of optimal angles in machining?

Using the right angles can lead to better performance. It reduces tool wear and increases speed. Knowing this can help both beginners and experts in their work.

Common Mistakes in Setting Angles

A list of frequent errors made by machinists regarding clearance and rake angles. Tips for accurately measuring and setting the correct angles.Many machinists make common mistakes with angles. Here are a few frequent errors:

- Incorrectly measuring clearance angles.

- Ignoring rake angles altogether.

- Using worn tools that change angles.

- Not double-checking settings before use.

To set angles correctly, follow these tips:

- Use precise measuring tools.

- Take your time when adjusting angles.

- Refer to guides or manuals to understand angle requirements.

Small errors can lead to big problems in machining. Always pay close attention!

What is the clearance angle in machining?

The clearance angle helps tools not to drag on the material. It ensures smooth cutting and reduces wear on the tool. Proper clearance delivers clean, efficient work.

What is the rake angle in machining?

The rake angle affects how sharp the cutting edge is. A good rake angle improves cutting efficiency and surface finish. It helps the tool cut more easily through the material.

Conclusion

In summary, lathe tool clearance and rake angle are important for effective cutting. Clearance helps prevent tool drag, while rake angle influences how easily the tool cuts material. Understanding both can improve your machining skills. Experiment with different settings on your lathe. We encourage you to read more about these concepts to enhance your projects and succeed in your work!FAQs

Sure! Here Are Five Questions Related To Lathe Tool Clearance And Rake Angle:Sure! Here are five questions about lathe tool clearance and rake angle: 1. **What is lathe tool clearance?** Lathe tool clearance is the space between the tool and the piece we’re working on. It helps the tool cut smoothly. 2. **Why is rake angle important?** Rake angle helps the tool cut better. A good angle makes it easier for the tool to slice through material. 3. **How does clearance affect cutting?** Good clearance helps avoid dragging or sticking. This means the tool works faster and makes better cuts. 4. **What happens with too little clearance?** If there’s too little clearance, the tool can get stuck. This can break the tool or ruin the workpiece. 5. **Can rake angle change the finish?** Yes! The right rake angle can make a smoother finish. It helps the tool cut cleanly without rough edges.

Sure! Please provide the question you would like me to answer.

What Is The Significance Of The Rake Angle In Determining The Cutting Efficiency Of A Lathe Tool?The rake angle is important because it affects how well a lathe tool cuts. A good rake angle helps the tool slice through the material easily. If the angle is too small or too big, it can wear down the tool faster or make cutting harder. So, choosing the right rake angle helps us work better and save time.

How Does Tool Clearance Angle Affect Chip Removal And Surface Finish During The Machining Process?The tool clearance angle helps the cutting tool slide easily over the material. A bigger angle lets chips move away better. This means less clogging, so we get a smoother surface. If the angle is too small, it can create rougher surfaces and more problems. Keeping the right angle is important for good work!

What Are The Common Rake Angle Values Used For Different Materials In Lathe Operations?In lathe operations, different materials need different rake angles for the best cut. For soft metals like aluminum, we use a rake angle of about 10 to 15 degrees. For harder metals like steel, a smaller angle of 5 to 10 degrees works better. For wood, a larger angle of 15 to 20 degrees can help make smoother cuts. Using the right angle helps make our work easier and more efficient.

In What Ways Can Improper Tool Clearance Lead To Tool Wear Or Failure During Turning Operations?When we don’t have enough space between the tool and the material, it can cause problems. The tool might rub against the material too much, making it get hot. This heat can wear out the tool quickly. If we don’t fix the space, the tool might even break. Keeping the right clearance helps the tool last longer and work better.

How Do The Rake Angle And Clearance Angle Interact To Influence The Temperature Generated At The Cutting Edge During Machining?The rake angle is the tilt of the cutting tool, while the clearance angle helps keep the tool from rubbing against the workpiece. When you change the rake angle, it can help cut more easily, making less heat. The clearance angle also helps by allowing room for the tool to move smoothly, reducing friction. Lower friction means lower temperature at the cutting edge. Together, they help keep the tool cooler while cutting.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Questions Related To Lathe Tool Clearance And Rake Angle:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are five questions about lathe tool clearance and rake angle: 1. **What is lathe tool clearance?** Lathe tool clearance is the space between the tool and the piece we’re working on. It helps the tool cut smoothly. 2. **Why is rake angle important?** Rake angle helps the tool cut better. A good angle makes it easier for the tool to slice through material. 3. **How does clearance affect cutting?** Good clearance helps avoid dragging or sticking. This means the tool works faster and makes better cuts. 4. **What happens with too little clearance?** If there’s too little clearance, the tool can get stuck. This can break the tool or ruin the workpiece. 5. **Can rake angle change the finish?** Yes! The right rake angle can make a smoother finish. It helps the tool cut cleanly without rough edges.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you would like me to answer.”}},{“@type”: “Question”,”name”: “What Is The Significance Of The Rake Angle In Determining The Cutting Efficiency Of A Lathe Tool?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The rake angle is important because it affects how well a lathe tool cuts. A good rake angle helps the tool slice through the material easily. If the angle is too small or too big, it can wear down the tool faster or make cutting harder. So, choosing the right rake angle helps us work better and save time.”}},{“@type”: “Question”,”name”: “How Does Tool Clearance Angle Affect Chip Removal And Surface Finish During The Machining Process?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The tool clearance angle helps the cutting tool slide easily over the material. A bigger angle lets chips move away better. This means less clogging, so we get a smoother surface. If the angle is too small, it can create rougher surfaces and more problems. Keeping the right angle is important for good work!”}},{“@type”: “Question”,”name”: “What Are The Common Rake Angle Values Used For Different Materials In Lathe Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “In lathe operations, different materials need different rake angles for the best cut. For soft metals like aluminum, we use a rake angle of about 10 to 15 degrees. For harder metals like steel, a smaller angle of 5 to 10 degrees works better. For wood, a larger angle of 15 to 20 degrees can help make smoother cuts. Using the right angle helps make our work easier and more efficient.”}},{“@type”: “Question”,”name”: “In What Ways Can Improper Tool Clearance Lead To Tool Wear Or Failure During Turning Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When we don’t have enough space between the tool and the material, it can cause problems. The tool might rub against the material too much, making it get hot. This heat can wear out the tool quickly. If we don’t fix the space, the tool might even break. Keeping the right clearance helps the tool last longer and work better.”}},{“@type”: “Question”,”name”: “How Do The Rake Angle And Clearance Angle Interact To Influence The Temperature Generated At The Cutting Edge During Machining?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The rake angle is the tilt of the cutting tool, while the clearance angle helps keep the tool from rubbing against the workpiece. When you change the rake angle, it can help cut more easily, making less heat. The clearance angle also helps by allowing room for the tool to move smoothly, reducing friction. Lower friction means lower temperature at the cutting edge. Together, they help keep the tool cooler while cutting.”}}]}