Have you ever wondered how craftsmen choose the best tools for their projects? One important choice is the lathe tool nose radius. This small feature plays a big role in shaping materials. But what exactly is it and how does it affect your work?

The lathe tool nose radius is the rounded tip of the cutting tool. Think about it like the edge of a pencil. A sharp point can make fine lines, but a rounded tip can create smooth, flowing curves. The right nose radius can help achieve the perfect finish on your piece.

Choosing the right lathe tool nose radius is like picking the right paintbrush for a masterpiece. Each project has its own needs. A large nose radius is great for removing material quickly. On the other hand, a smaller radius works wonders for delicate details.

Did you know that the wrong nose radius can lead to poor results? Imagine trying to bake a cake without the right pan. It just won’t turn out the way you want. Selecting the right lathe tool nose radius can make all the difference in the quality of your work.

So, whether you are a beginner or an experienced machinist, it’s essential to understand this aspect of tool selection. Let’s explore how to choose the perfect lathe tool nose radius for your needs!

Lathe Tool Nose Radius Selection: Tips For Optimal Performance

Understanding Lathe Tool Nose Radius Selection

Choosing the right lathe tool nose radius can make a big difference in machining. A larger radius usually reduces cutting force and improves surface finish. However, it can limit your ability to make sharp corners. What’s more important: speed or precision? Each project demands careful thought. Did you know that even a small change in nose radius can affect tool life? Proper selection helps achieve better results and saves money in the long run.Understanding Lathe Tool Geometry

Definition of tool geometry and its significance in machining.. Components of tool geometry: cutting edge, nose radius, and more..Tool geometry is like the blueprint for how a lathe tool works. It shows where the cutting edge meets the workpiece. Understanding this helps in getting smooth finishes and precise shapes. The components of this geometry include the cutting edge, which does the cutting, and the nose radius, which smooths corners. Think of the nose radius as the hug your tool gives to materials—no sharp jabs, just gentle touches!

| Component | Function |

|---|---|

| Cuts Edge | Actually cuts the material. |

| Nose Radius | Smooths the corners. |

The Importance of Nose Radius in Machining

Role of nose radius in surface finish quality.. Impact of nose radius on tool strength and wear resistance..The nose radius plays a crucial role in machining. It affects how smooth the surface looks. A well-chosen radius gives a better finish. It also acts as a cushion during cutting. This reduces the tool’s wear and tear, making it last longer. Strong tools with the right radius handle tough materials better. A good nose radius increases durability and cuts costs.

Why does nose radius matter?

Nose radius impacts surface finish quality and tool strength. A good radius ensures a smoother surface. It also helps tools resist wear. Choosing the right radius prevents damage and saves money.

Key benefits of nose radius:

- Improved surface finish

- Increased tool lifespan

- Better strength during machining

Factors Influencing Nose Radius Selection

Material type and its influence on nose radius choice.. The relationship between cutting speed and nose radius requirements..Choosing the right nose radius for lathe tools can feel like picking toppings for a pizza — it depends on what you’re working with! Different materials need different radii for the best results. Hard metals may require a sharper nose, while softer ones benefit from a larger radius. Also, cutting speed plays a big role; faster speeds often call for a smaller nose radius to prevent chipping. Too much speed with a big radius? You might as well be trying to slice cheese with a hammer!

| Material Type | Recommended Nose Radius |

|---|---|

| Steel | 0.8 – 1.2 mm |

| Aluminum | 1.0 – 2.0 mm |

| Copper | 0.6 – 1.0 mm |

Choosing the Right Lathe Tool for Your Project

Key criteria for selecting lathe tools based on nose radius.. How to match nose radius with machining operations and materials..Selecting the perfect lathe tool is like picking a favorite ice cream flavor. There are many options, and your choice matters! One key factor to consider is the nose radius. A larger nose radius can help with smoothing out curves, while a smaller one is great for sharp edges. Match this with your material type; for example, soft metals love larger radii. Check this handy table:

| Material Type | Recommended Nose Radius |

|---|---|

| Aluminum | Large |

| Steel | Medium |

| Brass | Small |

So, before you start machining, think about the nose radius as your magic wand for better results. The right choice can change your project from a “meh” to “wow!”

Techniques for Measuring Nose Radius

Methods to accurately measure the nose radius of tools.. Tools and instruments used in measuring nose radius..Measuring the nose radius precisely is important for cutting tools. There are different methods to do this. A common tool used is a radius gauge. It helps to find the curve of the nose. Another option is a micrometer, which measures small distances accurately. A coordinate measuring machine (CMM) is also great for very precise measurements.

What are some techniques for measuring nose radius?

Common techniques include using radius gauges, micrometers, and CMMs. These tools help ensure tools perform well in machines. Accurate measurements lead to better cuts.

Tools Used:

- Radius Gauge: Great for quick checks.

- Micrometer: Very precise for small measurements.

- Coordinate Measuring Machine: Best for high accuracy.

Best Practices for Lathe Tool Maintenance

Importance of maintaining nose radius for consistent performance.. Tips for prolonging the life of lathe tools through proper care..Keeping lathe tools in great shape means having fun while working! A well-maintained nose radius helps your tools perform consistently. Think of it like your favorite pair of shoes; if they’re worn out, you might trip! To prolong the life of your tools, always clean them after use and check for wear. Regular sharpening is key as well. A sharp tool is a happy tool!

| Tip | Description |

|---|---|

| Clean Regularly | Keep tools free of debris to avoid damage. |

| Check for Wear | Inspect tools often to catch issues early. |

| Sharpen Frequently | A sharp tool cuts better and lasts longer. |

Remember, a little care goes a long way! Happy turning!

Troubleshooting Common Issues Related to Nose Radius

Identifying problems caused by inappropriate nose radius.. Solutions and adjustments for optimizing cutting performance..Troubles with nose radius can slow down work. If your lathe tool has the wrong nose radius, it can cause issues like poor cutting quality or tool wear. Here are some common problems:

- Inconsistent surface finish

- Excessive tool wear

- Chatter during cutting

To fix these problems and boost performance, consider these solutions:

- Choose the right nose radius for your material.

- Adjust cutting speed and feed rate.

- Check for tool alignment.

By making these adjustments, you can improve cutting efficiency and extend tool life.

Why is the correct nose radius important?

The right nose radius ensures smoother cuts and reduces wear on tools. It helps to lower the risk of mistakes and makes your work easier.

Conclusion

In summary, choosing the right lathe tool nose radius is crucial for excellent machining results. A larger radius improves surface finish, while a smaller one helps with tight tolerances. Consider your project needs to make the best choice. We encourage you to explore more about lathe tools and practice your selections for better outcomes. Happy machining!FAQs

How Does The Nose Radius Of A Lathe Tool Influence The Quality Of The Surface Finish On Machined Parts?The nose radius of a lathe tool is the rounded tip on the tool. A bigger nose radius makes a smoother cut, which can look nicer on the part you’re making. If the radius is too small, the tool can leave rough spots. So, choosing the right nose radius helps us make better-looking surfaces on the things we build.

What Factors Should Be Considered When Selecting The Appropriate Tool Nose Radius For Different Materials?When you choose a tool nose radius, think about the material you are working with. Softer materials need a larger radius for a smooth finish. Harder materials work better with a smaller radius for more control. You should also consider how much pressure you will use and the shape you want to make. All these things help you pick the right tool!

How Does The Nose Radius Affect Cutting Forces And Tool Wear During Turning Operations?The nose radius is the rounded tip of a cutting tool. A bigger nose radius helps spread the cutting force. This means the tool feels less pressure, which can help it last longer. With less wear, you can use the tool for a longer time before it needs replacing. So, a bigger nose radius is often better for cutting!

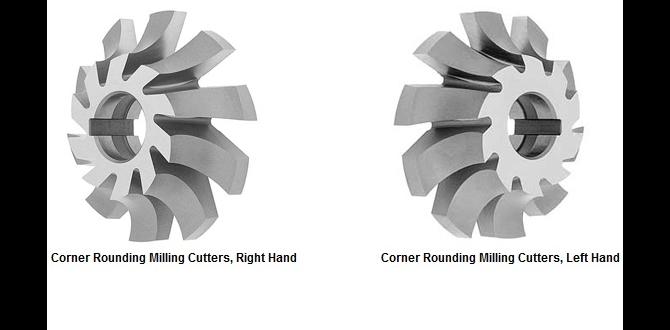

In Which Specific Applications Or Machining Operations Is A Larger Nose Radius Preferred, And Why?A larger nose radius is preferred in operations like turning and milling. It helps make smoother shapes, which is great for curved designs. When we use a larger nose, it reduces the chances of breaking the tool. This makes our work last longer and look nicer. Plus, it creates less friction, making the whole process easier!

What Are The Industry Standards Or Guidelines For Determining The Optimal Nose Radius For Various Lathe Tooling Geometries?To find the best nose radius for lathe tools, we consider a few simple rules. First, the nose radius should match the material you are cutting. Softer materials need a larger radius, while harder materials work well with a smaller one. You should also think about how thick the part is. Thicker parts might need a bigger radius for better cutting. Finally, it helps to follow guidelines from tool manufacturers to get the best results.