Have you ever struggled with your lathe while trying to get a perfect cut? A wobbly tool rest can turn your woodworking dreams into a nightmare. It’s frustrating when the tool rest just won’t stay in place. You want a smooth finish, not a messy one.

What if I told you that fixing a lathe tool rest locking mechanism is easier than you think? Many woodworkers face this issue, but few know the simple steps to solve it. By understanding your tool’s locking mechanism, you can keep it steady and ensure your projects look amazing.

Did you know that a well-secured tool rest can improve your accuracy? A stable tool can help you create fine details and smooth edges. In this article, we will explore how to fix that pesky lathe tool rest locking mechanism. You’ll gain confidence in your skills, and your lathe will work like a charm.

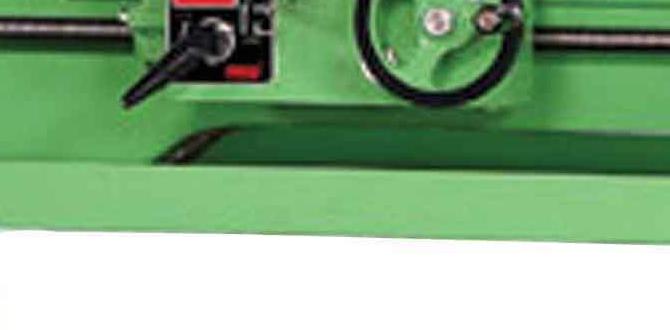

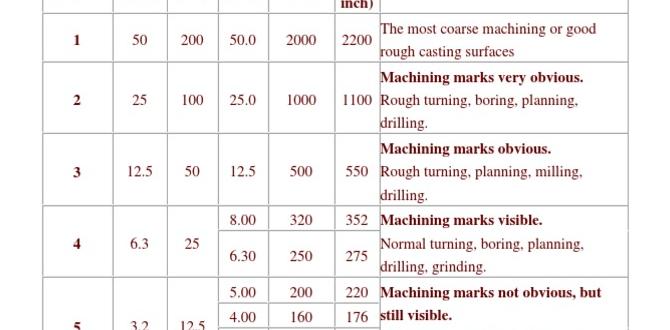

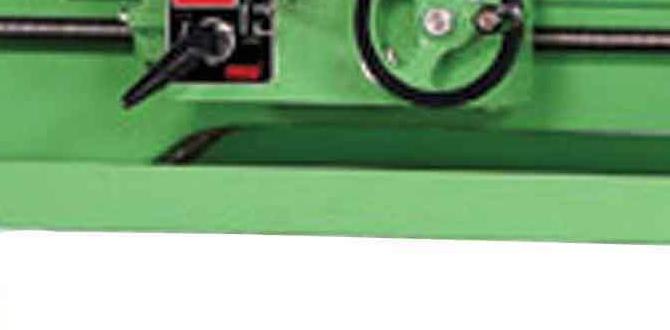

Lathe Tool Rest Locking Mechanism Fix: A Complete Guide When Dealing With A Lathe, The Effectiveness And Precision Of Your Work Are Often Determined By The Quality Of Your Tool Rest. One Common Issue That Users Face Is The Locking Mechanism Of The Lathe Tool Rest. A Malfunctioning Locking Mechanism Can Lead To Frustrating Adjustments And Even Unsafe Working Conditions. In This Article, We Will Explore How To Fix A Lathe Tool Rest Locking Mechanism, Ensuring That Your Lathe Operates Smoothly And Safely. Understanding The Lathe Tool Rest Locking Mechanism The Lathe Tool Rest Locking Mechanism Is Designed To Secure The Tool Rest In Place, Allowing You To Make Precise Cuts Without Worrying About The Rest Shifting Unexpectedly. Typically, This Mechanism Consists Of A Lever Or Knob That Clamps The Tool Rest To The Lathe Bed. Over Time, Wear And Tear Or Improper Use Can Lead To Mechanical Failures, Requiring A Fix To Restore Proper Function. Common Issues With The Locking Mechanism 1. **Worn Out Components**: The Most Frequent Problem Is The Gradual Wear Of The Locking Components. This Can Include The Lever, Knob, Or Even The Threads That Allow Movement. 2. **Debris Buildup**: Dust, Wood Shavings, And Other Debris Can Accumulate In The Locking Mechanism, Preventing It From Functioning Correctly. 3. **Improper Adjustment**: Occasionally, The Locking Mechanism May Become Loose Or Require Recalibration To Ensure It Holds The Tool Rest Firmly. Steps To Fix The Lathe Tool Rest Locking Mechanism 1. **Inspect The Mechanism**: Start By Examining The Locking Mechanism For Wear. Look For Any Broken Parts Or Excessive Play In The Lever Or Knob. 2. **Clean The Components**: Use A Brush Or Compressed Air To Remove Debris From The Mechanism. Ensure That All Accessible Parts Are Clean, As Dirt Can Impede Movement. 3. **Lubricate Moving Parts**: If The Mechanism Feels Stiff, Apply A Suitable Lubricant To The Moving Components. This Will Help Them Function Smoothly And Prevent Future Sticking Or Malfunction. 4. **Replace Worn Parts**: If You Notice Any Components That Are Damaged Or Excessively Worn, Consider Replacing Them. Many Manufacturers Offer Replacement Parts For Specific Lathe Models. 5. **Recalibrate**: Once Everything Is Clean And Any Worn Parts Are Replaced, Test The Mechanism. Adjust As Necessary To Ensure The Tool Rest Is Secure And Can Be Locked Easily. Preventive Measures To Maintain The Longevity Of Your Lathe Tool Rest Locking Mechanism, Implement Regular Cleaning And Lubrication Routines. Additionally, Avoid Overtightening The Mechanism, Which Can Accelerate Wear And Damage Components Over Time. Conclusion Addressing Issues With Your Lathe Tool Rest Locking Mechanism Can Significantly Enhance Your Woodworking Experience. By Following These Simple Steps For Inspection, Cleaning, Lubrication, And Replacement, You Can Ensure That Your Lathe Remains A Reliable Tool In Your Workshop. Regular Maintenance Will Not Only Prolong The Life Of Your Lathe Components But Also Improve The Overall Safety And Precision Of Your Work.

Lathe Tool Rest Locking Mechanism Fix

Is your lathe tool rest locking mechanism giving you trouble? It can be frustrating when it fails. First, check for any wear and tear. Sometimes, a simple tightening of screws can solve the issue. If that doesn’t work, consider replacing worn parts. A well-functioning locking mechanism is crucial for precise cuts. Did you know that a secure tool rest can improve your projects significantly? Taking care of this small piece can lead to big improvements in your craftsmanship.Understanding the Lathe Tool Rest Locking Mechanism

Explanation of the locking mechanism components. Importance of a properly functioning locking system.The lathe tool rest locking mechanism has some key parts that work together. Think of it like a team! There’s the lock knob, the locking lever, and the guide rail. Each of these pieces is important for keeping the tool rest steady. A well-functioning locking system matters like a good pizza crust—without it, everything falls apart! If the lock doesn’t hold, your projects can turn messy. No one wants their wood to spin out of control, right?

| Component | Function |

|---|---|

| Lock Knob | Secures the tool rest in place |

| Locking Lever | Engages the lock mechanism |

| Guide Rail | Provides a stable path for the tool rest |

Common Issues with Lathe Tool Rest Locking Mechanisms

Description of frequent problems faced by users. Signs that indicate a faulty locking mechanism.Users often face issues with lathe tool rest locking mechanisms. Common problems include difficulty in locking the tool rest firmly. Sometimes, it may slide during use, which is unsafe. Other times, it may seem stuck and won’t release. Signs of a faulty locking mechanism are:

- Tool rest moves while working.

- Locking lever feels loose or wobbly.

- Hard to adjust or tighten the mechanism.

If you notice these signs, it’s time to inspect and possibly fix the locking mechanism.

What are the signs of a faulty lathe tool rest locking mechanism?

Signs include difficulty locking, sliding during use, and a loose locking lever.

Tools and Materials Needed for Fixing the Locking Mechanism

List of essential tools for the repair process. Recommended materials and replacement parts.To fix the locking mechanism, you will need some tools and materials. Here’s a quick list to help you. Using the right tools makes the job easier and safer.

- wrench – for tightening nuts

- screwdriver – for removing screws

- hammer – to tap parts into place

- pliers – for gripping small parts

- replacement parts – including screws and springs

Having these items ready will make fixing your lathe tool rest locking mechanism fast and effective.

What tools do you need to fix the lathe tool rest locking mechanism?

You will need a wrench, screwdriver, hammer, pliers, and some replacement parts. These tools help you easily repair the locking mechanism.

Step-by-Step Guide to Fixing the Locking Mechanism

Detailed instructions for disassembling the tool rest. Troubleshooting tips for common problems encountered during the fix.To fix the locking mechanism, start by taking apart the tool rest. Follow these steps:

- Unplug your lathe for safety.

- Remove screws holding the tool rest in place.

- Carefully lift off the tool rest top.

- Inspect the locking parts for damage.

If you encounter problems, try these tips:

- Check for any rust or dirt that may block movement.

- Make sure all screws and parts are tightly secured.

- Look for any broken pieces that need replacing.

For a smooth fix, patience is key!

What should I do if the locking mechanism is stuck?

First, clean and lubricate the area. Use a gentle cleaner and some oil. If it’s still stuck, check again for any loose screws. Tighten them if needed.

Preventative Maintenance for Lathe Tool Rest Locking Mechanisms

Best practices to avoid future locking issues. Routine maintenance checklist to ensure longevity.Keeping your lathe tool rest locking mechanism in good shape helps avoid future problems. Regular maintenance can save time and money. Here are some best practices:

- Check for wear and tear regularly.

- Clean the locking mechanism to remove dust or debris.

- Lubricate moving parts to ensure smooth operation.

- Test the locking function often.

A simple checklist will help maintain your tools and make them last longer. By doing these checks, you can enjoy your lathe without worries!

How can I fix locking issues?

To fix locking issues, locate the damaged parts and replace them. Ensure everything is tightened properly, and clean any rust.

Frequently Asked Questions about Lathe Tool Rest Issues

Common inquiries regarding repairs and maintenance. Expert answers and troubleshooting advice.Many people have questions about lathe tool rest issues. Here are some common concerns and simple answers.

How can I fix my tool rest if it keeps moving?

Check the locking mechanism first. Make sure it is clean and tight. If not, tighten the screws. Sometimes, a little oil helps move parts smoothly.

What should I do if my tool rest is not level?

Use a level tool. Place it on the rest. Adjust it by lifting or lowering one side until it is even.

How often should I maintain my lathe tool rest?

Regular checks are important. Clean it every few weeks and check for wear. This will help it work better and last longer.

Conclusion

In summary, fixing a lathe tool rest locking mechanism can improve your woodturning experience. Understand the parts and their functions. Regular maintenance helps prevent future issues. If you’re unsure, seek guidance or watch tutorial videos. Remember, a well-functioning tool rest makes your projects easier and more enjoyable. Let’s keep learning and improving our skills together!FAQs

What Are The Common Causes Of A Lathe Tool Rest Locking Mechanism Malfunction?A lathe tool rest locking mechanism can stop working for a few reasons. First, dirt or metal shavings can get stuck in it. Second, the screws might be loose or missing. Third, it could be rusty or damaged. Lastly, if you don’t use it correctly, it can break. Always keep it clean and check the parts!

How Can I Diagnose Issues With My Lathe Tool Rest Locking Mechanism?To check your lathe tool rest locking mechanism, start by looking for any visible damage or wear. Try tightening the lock to see if that helps. If it still doesn’t hold tight, clean any dust or debris from the area. Finally, if it still doesn’t work, ask someone who knows about tools for help.

What Steps Should I Follow To Fix A Loose Or Malfunctioning Lathe Tool Rest Locking Mechanism?To fix a loose or malfunctioning lathe tool rest locking mechanism, start by turning off the lathe. Look for the locking handle and check if it’s loose. Tighten it with a wrench if it is. If it still doesn’t work, check for dirt or rust and clean it. Finally, test the locking mechanism to see if it’s working correctly.

Are There Any Specific Tools Or Materials Needed To Repair A Lathe Tool Rest Locking Mechanism?Yes, you need a few tools to fix a lathe tool rest locking mechanism. You will need a wrench to unscrew parts. A screwdriver can help you tighten or loosen screws. Sometimes, you may need new parts if they are broken. Make sure to have some lubricant to keep things running smoothly.

How Can I Prevent Future Problems With My Lathe Tool Rest Locking Mechanism?To prevent problems with your lathe tool rest locking mechanism, keep it clean and free of dust. You should check it regularly for any loose parts. If you notice anything that looks worn out, fix it right away. Always tighten the lock securely before you start working. This will help keep everything in good shape!