Have you ever wondered how metal parts fit together perfectly? A lathe training course can teach you just that! Learning about metal lathe alignment is key for anyone who works with machines. Imagine creating a part that fits like a puzzle piece. It’s exciting to think about!

In many shops, workers need to know how to align a lathe correctly. A well-aligned lathe makes all the difference. With the right training, you can avoid mistakes and save time. Plus, it’s much safer!

Did you know that a misaligned lathe can cause parts to wear out faster? This could lead to costly repairs. By taking a lathe training course, you can learn how to keep your machine running smoothly.

So, why not dive into the world of metalworking? With the right skills, you can create amazing things. Let’s explore how lathe training can make you a pro at metal lathe alignment!

Comprehensive Lathe Training Course: Metal Lathe Alignment Techniques

Lathe Training Course: Metal Lathe Alignment

Metal lathe alignment is essential for accurate machining. A lathe training course teaches you the right techniques to ensure precision. You’ll learn about leveling the lathe, checking spindle alignment, and adjusting tailstock alignment. Did you know that even a tiny misalignment can lead to poor results? Understanding these concepts helps produce high-quality parts. This course can boost your skills and confidence in handling metal lathes. It’s an exciting journey into the world of machining!The Importance of Metal Lathe Alignment

Effects of misalignment on machining accuracy. Consequences of poor alignment on tool life and workpiece quality.Proper metal lathe alignment is crucial for good machining. If a lathe is misaligned, it can cause wrong cuts and poor shapes in metal pieces. This leads to lower quality and wasted material. When the alignment is off, tools wear out faster, lowering their lifespan. This means workers spend more money replacing tools. Proper alignment ensures better accuracy and longer tool life, which is essential for saving time and money in projects.

What happens if a lathe is not aligned correctly?

If a lathe is misaligned, it can lead to bad cuts and quick tool wear. This results in poor workpiece quality, wasting materials and resources. Keeping the lathe aligned helps maintain accuracy and improves tool longevity.

- Misalignment affects accuracy.

- It reduces tool life.

- Poor quality workpieces result.

Key Concepts in Lathe Alignment

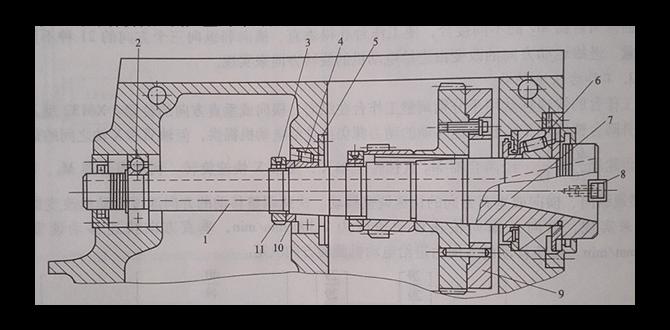

Explanation of terms: tailstock, headstock, and bed alignment. Types of alignment: horizontal, vertical, and angular.Understanding lathe alignment is key for precision work. The tailstock holds the end of the workpiece, while the headstock drives it. The bed is the long part where both are attached. Alignments can be:

- Horizontal: Side to side alignment.

- Vertical: Top to bottom alignment.

- Angular: Alignment for angles or slopes.

This knowledge helps you work better and avoid mistakes. Correct alignment improves accuracy and safety. Now, isn’t that important to know?

What are the terms used in lathe alignment?

The terms in lathe alignment include headstock, tailstock, and bed. These parts help the lathe work correctly.

Preparation for Alignment Procedures

Tools and equipment needed for alignment. Setting up the lathe for alignment checks.Getting ready to align your lathe? First, you’ll need some key tools. Think of them as your trusty sidekicks: a dial indicator, a level, and some shims. They’ll help check everything is just right. Next, set up your lathe properly. Make sure it’s on a sturdy surface. Picture this: a wobbly table makes for wobbly alignments! Keep your workspace tidy; nobody wants to trip over stray tools. Safety first!

| Tool | Purpose |

|---|---|

| Dial Indicator | Measures small distances and alignment |

| Level | Ensures the lathe is flat |

| Shims | Helps adjust machine parts |

Step-by-Step Lathe Alignment Techniques

Detailed process for aligning the tailstock. Techniques for aligning the headstock.Aligning the tailstock is crucial for precise metal lathe work. Start by loosening the tailstock clamp. Use a feeler gauge to check for gaps between the tailstock and the bed. Adjust the tailstock as needed until it fits snugly. Tighten the clamp firmly to hold it in place.

Next, focus on the headstock alignment. Use a dial indicator to check for any misalignment. Make small adjustments to the headstock position. This ensures your workpiece rotates smoothly and accurately.

- Check for gaps with a feeler gauge.

- Use a dial indicator for headstock setup.

- Make minor adjustments for perfect fit.

How do I know if my lathe is properly aligned?

To check lathe alignment, look for sawtooth patterns on your finished work. If you see these patterns, the lathe may need realignment. Pay attention to uneven wear, too. Both signs indicate it’s time to align again.

Common Alignment Mistakes and How to Avoid Them

List of frequent errors during alignment procedures. Tips for ensuring accurate alignments.During lathe alignment, several common mistakes can occur. Here’s a quick list of errors to avoid:

- Poor measurements

- Ignoring tool wear

- Skipping steps in the process

- Failure to secure the workpiece

To ensure accurate alignments, keep these tips in mind:

- Always double-check measurements.

- Use quality tools to avoid errors.

- Follow each step carefully.

- Secure your workpiece tightly.

Alignment mistakes can lead to poor results. Taking time to avoid them makes your work easier and more precise.

What are the benefits of avoiding alignment mistakes?

Avoiding alignment mistakes leads to better precision, fewer mistakes, and improved safety while working.

Practical Applications of Lathe Alignment in Projects

Realworld examples demonstrating the impact of proper alignment. Case studies highlighting alignment challenges and solutions.Proper lathe alignment can make a big difference in projects. Think about a school project where everything fits perfectly; that’s what good alignment does. For example:

- In one case, a team made a small error in setup. This led to uneven cuts and wasted materials. After fixing the alignment, their project quality improved greatly.

- Another team faced issues with vibrations. They realigned their lathe, and it made their work smoother. This helped them finish on time and with better results.

These examples show how proper alignment benefits all kinds of projects. It saves time and materials, leading to better success.

Why is lathe alignment important in real-world projects?

Proper lathe alignment can save money and time. Good alignment ensures better cuts, reducing waste and rework.

Advanced Training Opportunities and Resources

Recommended training courses and certifications in lathe operations. Online resources and communities for ongoing learning.If you’re eager to learn more about lathe operations, you’ve got plenty of options! Check out some recommended training courses and certifications that make you a pro. Online resources are also plentiful—think virtual classes, videos, and forums where you can ask all your burning questions. Remember, even the best experts never stop learning. So, hop onto these communities for tips and tricks. You never know when you might find a gold nugget of knowledge, or at least a good pun!

| Course/Certification | Provider | Format |

|---|---|---|

| Lathe Operations Basics | Skillshare | Online |

| Advanced Metalworking | Coursera | Online |

| Certification in Lathe Mastery | Local Community College | In-person |

Continuous Improvement through Feedback and Practice

Importance of practice in mastering alignment techniques. Seeking feedback from experienced machinists to enhance skills.Mastering alignment techniques takes practice. Like learning to ride a bike, you can’t expect to zoom around the block on your first try. Regular practice helps build your skills and confidence. Seeking feedback from experienced machinists is equally important. Why? They can spot mistakes that you might miss, like a cat seeing a laser pointer! Always ask for tips to sharpen your skills.

| Practice | Feedback |

|---|---|

| Builds confidence | Offers new perspectives |

| Improves skills | Helps avoid mistakes |

| Makes you fast | Encourages growth |

Remember, even experts started somewhere. Keep practicing and asking for feedback, and soon you’ll be a lathe alignment pro!

Conclusion

In summary, a lathe training course teaches you how to align metal lathes properly. This skill ensures accuracy and safety in your projects. You’ll learn hands-on techniques and important concepts. If you’re eager to improve your machining skills, consider enrolling in a course or reading more about lathe practices. Taking the next step can boost your confidence and capabilities!FAQs

Sure! Here Are Five Questions Related To A Lathe Training Course Focusing On Metal Lathe Alignment:Sure! Here are five questions you might ask about a lathe training course: 1. What is a lathe? A lathe is a machine that shapes metal or wood. It spins the material while a tool cuts it. 2. How do we check if the lathe is straight? We use a ruler or a special tool to see if it lines up correctly. 3. Why is alignment important? If the lathe is not straight, it can’t make good shapes. This can lead to mistakes. 4. What tools do we use for alignment? We might use a level, calipers, or a dial indicator. These help us measure and adjust. 5. How can we learn to align the lathe better? We can practice a lot and ask for help from our teacher. They can show us the right way.

Sure! Please provide the question you want me to answer, and I’ll help you with it.

What Are The Essential Steps For Aligning A Metal Lathe To Ensure Accurate Machining?To align a metal lathe, first, make sure it’s level. We can do this using a spirit level. Next, check the tailstock and headstock to ensure they are straight. You can use a dial gauge to measure this. Finally, tighten all the bolts and make sure everything is secure. This helps us make precise cuts.

How Do You Determine If A Lathe Is Properly Aligned Before Starting A Machining Operation?To check if a lathe is properly aligned, you can follow these steps. First, use a dial indicator to measure any wobbling. Then, check the tailstock and headstock. They should be straight with each other. Finally, adjust anything that is not aligned. This way, you ensure safe and precise work.

What Tools And Instruments Are Commonly Used For Metal Lathe Alignment In A Training Course Setting?In a metal lathe training course, we use a few important tools. We often use a ruler to measure straightness. A dial indicator helps us check if the metal is level. You might also see squares to make sure everything is at the right angles. Lastly, alignment blocks keep parts in the right place.

What Are Some Common Problems That Can Arise From Improper Lathe Alignment, And How Can They Be Identified?If a lathe is not lined up correctly, it can cause a few problems. You might see uneven cuts on your project. Sometimes, the machine might shake or make weird noises. To find these issues, you can check your cuts and listen for strange sounds. Regularly examining your lathe helps keep it working well.

How Does Regular Maintenance And Alignment Checks Impact The Overall Performance And Lifespan Of A Metal Lathe?Regular maintenance and alignment checks help keep a metal lathe working well. When you clean it and check for problems, it runs smoother. This means you can make better parts and work faster. Taking care of the lathe also helps it last longer, so you don’t need to buy a new one as soon.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Questions Related To A Lathe Training Course Focusing On Metal Lathe Alignment:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are five questions you might ask about a lathe training course: 1. What is a lathe? A lathe is a machine that shapes metal or wood. It spins the material while a tool cuts it. 2. How do we check if the lathe is straight? We use a ruler or a special tool to see if it lines up correctly. 3. Why is alignment important? If the lathe is not straight, it can’t make good shapes. This can lead to mistakes. 4. What tools do we use for alignment? We might use a level, calipers, or a dial indicator. These help us measure and adjust. 5. How can we learn to align the lathe better? We can practice a lot and ask for help from our teacher. They can show us the right way.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you want me to answer, and I’ll help you with it.”}},{“@type”: “Question”,”name”: “What Are The Essential Steps For Aligning A Metal Lathe To Ensure Accurate Machining?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To align a metal lathe, first, make sure it’s level. We can do this using a spirit level. Next, check the tailstock and headstock to ensure they are straight. You can use a dial gauge to measure this. Finally, tighten all the bolts and make sure everything is secure. This helps us make precise cuts.”}},{“@type”: “Question”,”name”: “How Do You Determine If A Lathe Is Properly Aligned Before Starting A Machining Operation?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To check if a lathe is properly aligned, you can follow these steps. First, use a dial indicator to measure any wobbling. Then, check the tailstock and headstock. They should be straight with each other. Finally, adjust anything that is not aligned. This way, you ensure safe and precise work.”}},{“@type”: “Question”,”name”: “What Tools And Instruments Are Commonly Used For Metal Lathe Alignment In A Training Course Setting?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “In a metal lathe training course, we use a few important tools. We often use a ruler to measure straightness. A dial indicator helps us check if the metal is level. You might also see squares to make sure everything is at the right angles. Lastly, alignment blocks keep parts in the right place.”}},{“@type”: “Question”,”name”: “What Are Some Common Problems That Can Arise From Improper Lathe Alignment, And How Can They Be Identified?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If a lathe is not lined up correctly, it can cause a few problems. You might see uneven cuts on your project. Sometimes, the machine might shake or make weird noises. To find these issues, you can check your cuts and listen for strange sounds. Regularly examining your lathe helps keep it working well.”}},{“@type”: “Question”,”name”: “How Does Regular Maintenance And Alignment Checks Impact The Overall Performance And Lifespan Of A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Regular maintenance and alignment checks help keep a metal lathe working well. When you clean it and check for problems, it runs smoother. This means you can make better parts and work faster. Taking care of the lathe also helps it last longer, so you don’t need to buy a new one as soon.”}}]}