Have you ever watched a lathe spin? It’s fascinating how it shapes metal. Using a lathe can seem tricky, but that’s where training comes in. A lathe training course can help you learn the ropes. You can discover how to use a metal lathe safely and effectively.

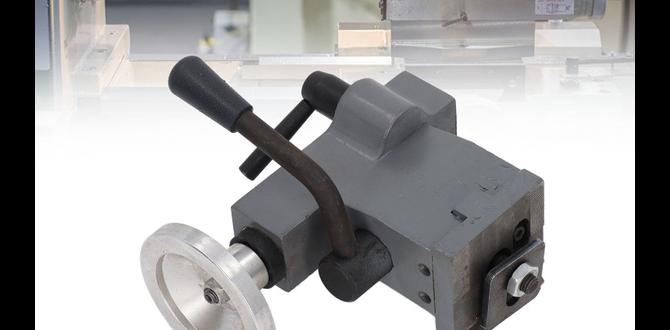

One important tool you’ll learn about is the quick change tool post. This handy device makes changing tools faster and easier. Imagine being able to switch tools without wasting time. Isn’t that exciting?

By taking a lathe training course, you’ll gain skills that can boost your projects. Whether you’re making a small part or a big masterpiece, knowing how to use a metal lathe will help you succeed. Do you want to turn your ideas into reality? Let’s dive into what these courses offer!

Lathe Training Course: Master Metal Lathe Quick Change Tool Post

Lathe Training Course: Metal Lathe Quick Change Tool Post

Are you curious about metalworking? A lathe training course can open doors to creativity and skill. One important feature you’ll learn about is the quick change tool post. This handy tool lets you switch between different cutting tools easily, saving you time and effort. Imagine being able to create precise parts without the hassle of constant adjustments! By mastering this technique, you can enhance your projects and enjoy the art of metal lathe work even more.Importance of Lathe Training

Benefits of proper training for safety and efficiency. How training can enhance skills and career opportunities.Learning how to use a lathe is very important. Proper lathe training helps keep you safe and makes work easier. With good training, you learn to avoid accidents. You also become faster and more skilled. This can lead to better job chances. Many companies prefer workers who are well-trained.

- Improved safety on the job.

- Faster and more efficient work.

- Better skills for future jobs.

- More career opportunities.

Why is lathe training important?

Lathe training helps workers stay safe while using machines. It also makes them more skilled, which can lead to promotions and better jobs. Companies want workers who know how to use tools safely.

Essential Skills Covered in Lathe Training Courses

Operation techniques for metal lathes. Tool setup and adjustments for precision work.In any lathe training course, students learn key operation techniques for metal lathes that transform raw materials into precise, beautifully crafted parts. They become pros at tool setup and adjustments to ensure everything works perfectly, adding that “wow” factor to their projects. Did you know that a well-set tool can save you up to 30% time? That’s enough to fit in an extra coffee break! Here’s a quick look at essential skills:

| Skill | Description |

|---|---|

| Operation Techniques | Learn how to control the lathe like a magician with a wand. |

| Tool Setup | Get tools aligned for that precision craft (no wobbling allowed)! |

| Adjustments | Tweak settings for custom work that fits like a glove. |

With these skills, you’ll be able to take on any project that comes your way. So, get ready to turn metal into magic!

Choosing the Right Lathe Training Course

Tips for finding accredited training programs. Factors to consider while selecting a training provider.Picking a good lathe training course is important for learning. Start by finding programs that are accredited. This means they meet high standards. Look for instructors with experience. Check their teaching style, too. Some key points to consider are:

- Reputation of the training provider

- Hands-on practice opportunities

- Course reviews from former students

- Location and cost

Make sure the program fits your goals for working with a metal lathe quick change tool post.

How do I find accredited lathe training programs?

Search for programs on official websites and education directories. You can also ask industry leaders or friends for recommendations. Read reviews to see what others liked or didn’t like.

Cost Factors for Lathe Training Courses

Typical costs associated with lathe training programs. ROI on investing in lathe training courses.The costs of lathe training courses can vary widely. Most programs range from several hundred to a few thousand dollars. Typical expenses include materials, instructor fees, and facility costs. Investing in lathe training has great return on investment (ROI). Trainees often find better job opportunities and higher pay after gaining new skills. It’s a smart move for anyone looking to advance their career.

What are typical costs for lathe training courses?

The costs for lathe training programs usually depend on factors like location, duration, and type of training. Courses can cost between $500 and $5,000. Some programs may even offer financial aid or scholarships.

Key cost factors:

- Instructor fees

- Course materials

- Duration of the program

Is it worth it to invest in lathe training?

Yes, investing in lathe training can lead to a higher salary. Studies show skilled workers earn 10-20% more. Employers value trained professionals for their enhanced skills.

Success Stories: Testimonials from Past Participants

Reallife examples of career advancement posttraining. Participant feedback on the effectiveness of the course.Many past participants experienced impressive career growth after training. They learned new skills that made them more valuable in their jobs. Here are some highlights from their stories:

- John got promoted to a supervisor after mastering advanced lathe techniques.

- Lisa found a better-paying job in less than a month.

- George started his own machine shop after gaining confidence from the course.

Participants often say the training helped them feel more qualified and ready for new opportunities. Their success shows how effective this lathe training course metal lathe quick change tool post can be.

What do participants say about the course?

Many participants praise the course for its hands-on approach and clear instructions. They feel prepared for real-world challenges. Feedback is very positive, highlighting the expertise of instructors and support from peers.

Success stories from past students inspire new learners. They show that with the right training, anyone can achieve their goals.

Next Steps After Completing Your Training

Certification and further learning opportunities. Networking and community engagement for ongoing support.After finishing your training, there are exciting choices ahead. You can earn a certification that shows you have skills. This can help you find jobs in the industry. Keep learning! Explore advanced courses in lathe techniques. Join community groups or forums. These can be great places to meet others who share your interests. Networking helps you gain new ideas and support. Stay connected and keep growing!

What certification options can I pursue?

Consider obtaining your certification in lathe operation. This can make you stand out in job applications. Many schools offer programs that help with this.

Ways to engage with the community:

- Join local workshops

- Participate in online forums

- Attend industry events

- Connect with mentors

Conclusion

In conclusion, a lathe training course teaches you essential skills for using a metal lathe. You learn about quick change tool posts, making work easier and faster. This knowledge improves your projects and prepares you for more advanced tasks. We encourage you to explore more about lathe training or practice with your own tools to gain confidence. Keep learning!FAQs

What Are The Key Advantages Of Using A Quick Change Tool Post On A Metal Lathe Compared To Traditional Tool Holders?Using a quick change tool post on a metal lathe has many benefits. First, it lets you switch tools fast, saving time. You can change tools without needing extra wrenches, which makes it easier. This means you can finish your work quicker and keep everything organized. Plus, it’s safer because you don’t have to fumble with tools while working.

What Are The Steps Involved In Installing A Quick Change Tool Post On A Metal Lathe?To install a quick change tool post on a metal lathe, first, we need to turn off the machine and unplug it. Next, remove the old tool holder by unscrewing it. Then, we place the new quick change tool post where the old one was. After that, we screw it tightly to keep it in place. Finally, we plug in the lathe again and check that everything works properly.

How Do You Properly Adjust And Align The Quick Change Tool Post For Optimal Cutting Performance?To adjust the quick change tool post, first, make sure it’s clean and tight. You need to loosen the screws gently. Then, move the tool until it lines up with the center of your workpiece. After that, tighten the screws again to keep it in place. Finally, check the height and make small adjustments if needed for smooth cutting.

What Types Of Tools And Accessories Can Be Used With A Quick Change Tool Post In A Metal Lathe Setup?In a metal lathe setup with a quick change tool post, you can use different tools. You might use cutting tools to shape metal pieces. There are also boring tools to make holes. Plus, you can add turning tools for making round shapes. Accessories like tool holders keep everything in place.

What Safety Precautions Should Be Taken When Operating A Metal Lathe With A Quick Change Tool Post?When using a metal lathe, we need to be very careful. Always wear safety goggles to protect your eyes. Keep your hands away from moving parts. Make sure your hair and clothes are secured so they don’t get caught. Lastly, don’t rush; take your time and stay focused.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Key Advantages Of Using A Quick Change Tool Post On A Metal Lathe Compared To Traditional Tool Holders? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Using a quick change tool post on a metal lathe has many benefits. First, it lets you switch tools fast, saving time. You can change tools without needing extra wrenches, which makes it easier. This means you can finish your work quicker and keep everything organized. Plus, it’s safer because you don’t have to fumble with tools while working.”}},{“@type”: “Question”,”name”: “What Are The Steps Involved In Installing A Quick Change Tool Post On A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To install a quick change tool post on a metal lathe, first, we need to turn off the machine and unplug it. Next, remove the old tool holder by unscrewing it. Then, we place the new quick change tool post where the old one was. After that, we screw it tightly to keep it in place. Finally, we plug in the lathe again and check that everything works properly.”}},{“@type”: “Question”,”name”: “How Do You Properly Adjust And Align The Quick Change Tool Post For Optimal Cutting Performance? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To adjust the quick change tool post, first, make sure it’s clean and tight. You need to loosen the screws gently. Then, move the tool until it lines up with the center of your workpiece. After that, tighten the screws again to keep it in place. Finally, check the height and make small adjustments if needed for smooth cutting.”}},{“@type”: “Question”,”name”: “What Types Of Tools And Accessories Can Be Used With A Quick Change Tool Post In A Metal Lathe Setup? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “In a metal lathe setup with a quick change tool post, you can use different tools. You might use cutting tools to shape metal pieces. There are also boring tools to make holes. Plus, you can add turning tools for making round shapes. Accessories like tool holders keep everything in place.”}},{“@type”: “Question”,”name”: “What Safety Precautions Should Be Taken When Operating A Metal Lathe With A Quick Change Tool Post? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using a metal lathe, we need to be very careful. Always wear safety goggles to protect your eyes. Keep your hands away from moving parts. Make sure your hair and clothes are secured so they don’t get caught. Lastly, don’t rush; take your time and stay focused.”}}]}