Have you ever wondered how to create beautiful curved shapes from wood or metal? The answer lies in a fascinating technique called lathe turning. This method allows craftsmen to shape materials into smooth spindles, perfect for furniture or decorative items.

Picture a master woodworker standing by a lathe, transforming a simple piece of wood into a stunning curved spindle. As the wood spins, the tool glides along, carefully sculpting the design. The result? A flawless piece that showcases the beauty of craftsmanship.

Lathe turning curved spindle layout is not just about skill; it’s also about understanding how to plan your cuts and shapes. Every detail counts! Did you know that the right layout can make the turning process easier and more enjoyable? Learning these techniques can open up a world of creativity.

So, whether you’re a beginner or a seasoned pro, dive into the world of lathe turning. Discover how to master the art of shaping curved spindles. Your next project might just surprise you!

Lathe Turning Curved Spindle Layout: Techniques And Tips

Lathe Turning Curved Spindle Layout

Creating a curved spindle on a lathe can be exciting and rewarding. This process involves understanding how to position the workpiece for the best results. You learn about the importance of the spindle’s angle and how it affects the final shape. Did you know that small adjustments can make a big difference in the curvature? Mastering lathe turning saves time and produces stunning results. Enjoy crafting unique designs with this skill!Importance of Curved Spindle Designs

Advantages of using curved spindles in various applications. Common industries that utilize curved spindle designs.Curved spindles have many advantages. They are strong and can support more weight. This makes them perfect for different tasks. Curved designs allow for smoother operations, which means less wear and tear.

- Used in furniture making for unique chair legs.

- Found in automotive parts for better performance.

- Used in machinery for precise movements.

What are the benefits of curved spindle designs?

Curved spindles improve strength, stability, and performance in various applications. They help reduce friction and wear, making machines last longer.

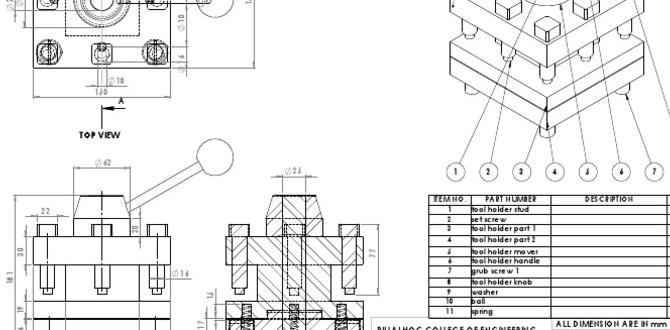

Fundamentals of Spindle Layout

Key components of a spindle layout. Factors affecting spindle design and performance.Understanding spindle layout is important. It affects how well machines work. Key parts of a spindle layout include:

- Spindle Shaft: This is the main part that spins.

- Bearings: These help the shaft rotate smoothly.

- Motor: It provides the power to turn the spindle.

Several factors can impact spindle design and performance:

- Speed: How fast the spindle spins affects its work.

- Material: Strong materials lead to better performance.

- Balance: A well-balanced spindle reduces vibrations.

These components and factors help create a strong and effective spindle layout.

What affects spindle performance?

Spindle performance is affected by speed, material, and balance. Each factor plays a key role in how smoothly and effectively the spindle works.

Techniques for Turning Curved Spindles

Stepbystep process for turning curved spindles. Tips for optimizing accuracy and precision.Turning curved spindles requires careful steps for the best results. Start by selecting the right materials. Measure your curves accurately. Here’s how you can do it:

- Secure the workpiece on the lathe.

- Create a detailed layout of the curve.

- Use a steady hand while cutting.

- Check your progress often.

For improved accuracy, keep these tips in mind:

- Use sharp tools for smooth cuts.

- Control the speed of the lathe.

- Always wear safety gear.

With practice, your curved spindles will look great!

How can you ensure accuracy while turning curved spindles?

To ensure accuracy, use sharp tools, control the lathe speed, and measure your work frequently. This way, you can correct mistakes quickly and get perfect shapes.

Common Challenges in Curved Spindle Turning

Potential issues faced during the turning process. Solutions to overcome common challenges.Turning a curved spindle can be tricky. One common issue is uneven surfaces. This may cause wobbling. Another issue is tool wear, which can lower quality. It’s important to address these problems quickly. Here are some ways to help:

- Use sharp tools for smooth cuts.

- Adjust the speed carefully to match the material.

- Regularly check your work for mistakes.

These solutions can make turning curved spindles easier and more precise.

What are common problems in spindle turning?

Common problems include uneven surfaces, tool wear, and vibrations.

Tools and Accessories for Efficient Turning

Recommended lathe tools for curved spindle projects. Accessories that enhance the turning experience.Choosing the right tools is key for turning curved spindles. Here are some must-have lathe tools:

- Roughing Gouge: Great for shaping the wood quickly.

- Sorby Spindle Gouge: Perfect for detailed cuts.

- Skew Chisel: Ideal for smooth finishes.

Along with tools, accessories enhance your experience:

- Faceplate: Holds the wood securely.

- Safety Glasses: Protect your eyes while working.

- Dust Masks: Keep you safe from wood dust.

What lathe tools are recommended for spindle projects?

Roughing gouges and skew chisels are recommended tools for spindle projects. They help create smooth curves and strong details. Good tools make your work easier and more fun!

Safety Considerations in Lathe Turning

Essential safety measures to ensure operator safety. Best practices for maintaining a safe working environment.Using a lathe can be fun, but safety should always come first. To stay safe while lathe turning, operators should wear goggles and gloves. Hair and loose clothes should be tied back. It’s crucial to keep the area tidy—no one wants to trip over a random toolbox! Also, check the equipment before starting. Here’s a quick safety checklist:

| Safety Measure | Importance |

|---|---|

| Wear goggles | Protects your eyes from debris |

| Secure loose clothing | Prevents accidents |

| Keep tools organized | Reduces tripping hazards |

Following these steps can make your woodworking a safer and more enjoyable experience—not a game of dodgeball with flying wood chips!

Case Studies and Practical Applications

Realworld examples of curved spindle projects. Lessons learned from successful spindle designs.Many projects use curved spindles in creative ways. One example is furniture design, where spindles add elegance and comfort. Another case is in musical instruments, enhancing sound and beauty. From these projects, designers learned valuable lessons:

- Shape matters: Curved designs can be stunning.

- Balance is key: Proper weight creates stability.

- Material choice: Strong materials last longer.

These insights help craftsmen create better curved spindle projects.

What are real-world examples of curved spindle projects?

Examples include elegant furniture, artistic sculptures, and musical instruments. Curved spindles enhance both function and style in these items.

Future Trends in Lathe Turning Technology

Emerging technologies impacting spindle design. Predictions for the future of lathe turning techniques.Technology is shaping the future of lathe turning, especially with spindle designs. New materials, like carbon fiber, are making spindles lighter and stronger. Plus, 3D printing is taking center stage, allowing for unique shapes. This means more fun for makers! Predictions show that machines will become smarter, using AI to optimize turning techniques. Soon, we may even have robots that do the turning while we grab snacks!

| Emerging Technologies | Impact on Spindle Design |

|---|---|

| Carbon Fiber | Lighter and stronger spindles |

| 3D Printing | Unique shapes, more creativity |

| AI Integration | Smarter turning, less manual work |

With these trends, the future looks bright and fun in lathe turning!

Conclusion

In summary, lathe turning curved spindle layouts are essential for creating smooth, rounded shapes. You need to understand the setup and measurements for success. Remember, practice makes perfect! We encourage you to try working on your own projects. Explore more resources or tutorials to improve your skills. Soon, you’ll be crafting impressive curved pieces with ease!FAQs

Certainly! Here Are Five Related Questions On The Topic Of Lathe Turning Curved Spindle Layout:Sure! A lathe is a machine that helps us shape wood or metal. When we turn a curved spindle, we carefully plan the design first. You need to measure the parts to make them fit together. It’s important to keep the tool steady while working. This way, we create smooth and nice shapes.

Sure! Please ask your question, and I’ll do my best to help you.

What Are The Key Considerations When Designing A Curved Spindle Layout For A Lathe Turning Project?When designing a curved spindle layout for a lathe turning project, you should think about the shape you want to create. Make sure the spindle can help shape the material easily. You also need to consider the space around you to work without any problems. Finally, check that everything fits well so it runs smoothly and safely.

How Do You Choose The Appropriate Tools And Cutting Speeds For Turning A Curved Spindle On A Lathe?To choose the right tools for turning a curved spindle, you need a special cutting tool called a lathe tool. Look for one that fits the shape of the spindle. Next, set the cutting speed based on the material you’re using. Softer materials work well with faster speeds, while harder ones need slower speeds. Always test your setup first to make sure it works safely.

What Techniques Can Be Employed To Ensure Accuracy And Consistency When Shaping A Curved Spindle On A Lathe?To shape a curved spindle on a lathe, you can use a few simple techniques. First, keep measuring as you work. Use a caliper to check your curve often. Next, move the tool gently and steadily to keep the shape smooth. Finally, go slowly and take small cuts, so you don’t remove too much wood at once.

How Does The Material Of The Spindle Affect The Lathe Turning Process For Curved Designs?The spindle is part of the lathe that holds the material you’re working on. If the spindle is made of strong metal, it can help create smooth curves. A strong spindle won’t bend or shake, making it easier to control. If it’s weak, you might get wobbly or uneven designs. So, the right spindle makes your curved designs look better!

What Safety Precautions Should Be Taken Into Account When Working On A Lathe To Turn A Curved Spindle?When using a lathe to turn a curved spindle, you should always wear safety glasses to protect your eyes. Make sure your hair and clothes are tucked in so they don’t get caught in the machine. Keep your hands away from the spinning part. Stand clear of the lathe while it’s working. Lastly, follow all the safety rules to stay safe while you work.