Have you ever wondered how to make wood projects shine? Choosing the right finish can be tricky. Many woodworkers often ask, “Should I use lathe turning sanding sealer or shellac?” Both have their strengths, but they work very differently.

Imagine crafting a beautiful bowl. You want it to look perfect. Then, you see two options for finishing. One promises a quick dry time, while the other offers a rich, deep color. Which do you choose? This decision matters. It can change how your project looks and feels.

Did you know that sanding sealer helps protect the wood before final coats? On the other hand, shellac gives a classic finish that many woodworkers love. Each product has its fans and unique benefits. Understanding these differences can help you decide the best choice for your projects.

Let’s dive deeper into the world of lathe turning sanding sealer and shellac. With the right knowledge, you can make your wood creations pop! Are you ready to find out which finish fits your style?

Lathe Turning: Sanding Sealer Vs Shellac Explained

Understanding Sanding Sealers

Definition and purpose of sanding sealers in woodturning. Common types of sanding sealers used in lathe turning.

Sanding sealers are special liquids used on wood. They help prepare the surface before finishing. Their main purpose is to fill small gaps and make the wood smooth. This means the final finish looks great and lasts longer. Common types include:

- Water-based sanding sealers – Quick drying and low odor.

- Oil-based sanding sealers – Provide a rich finish and deep color.

- Shellac-based sanding sealers – Fast drying with a warm tone.

What are the benefits of using sanding sealers in woodturning?

Using sanding sealers helps achieve a smoother surface and better appearance. It supports overall durability. Sealers also prevent issues like blotching. This leads to a more professional look.

Comparison of Sanding Sealers and Shellac

Key differences in composition and application methods. Drying times and curing processes.

Sanding sealers and shellac serve different purposes in woodworking. They differ in what they are made of and how we use them. Here’s a simple comparison:

- Composition: Sanding sealers are usually made from synthetic resins. Shellac is natural, made from bug secretions.

- Application: Use a brush or spray for both, but sanding sealers need less preparation.

- Drying Times: Sanding sealers dry quickly, about 30 minutes. Shellac takes longer, often 1 to 2 hours.

- Curing Process: Sanding sealers cure fast. Shellac can take days to fully harden.

Choosing between them depends on your project needs!

What is the best use for sanding sealers and shellac?

Sanding sealers are great for quick finishes. Shellac is better when a natural look is needed for furniture.

Advantages of Using Sanding Sealers

Benefits regarding finishing requirements and ease of use. Compatibility with various wood types.

Using sanding sealers has clear benefits. They make finishing work easier and faster. Here are some key points:

- Easy to Apply: Sanding sealers go on smoothly and dry quickly.

- Fine Finish: They create a nice base for paint or varnish.

- Compatible: Works well with many wood types, like oak and pine.

These sealers help protect your wood while making it look great. They save time and effort, which is ideal for anyone working with wood!

What are the benefits of sanding sealers?

The benefits of sanding sealers are clear. They offer a quick and easy finishing process. They also ensure good results on various types of wood.

Advantages of Using Shellac

Unique properties such as clarity and depth of finish. Benefits of natural materials and ease of repair.

Shellac has some great perks for your projects. It gives a clear and deep finish, making wood look beautiful. Using natural materials, it’s safe and friendly for the environment. If you make a mistake, it’s easy to fix. A quick touch-up can save the day. Many woodworkers love these qualities. It’s no wonder why shellac is a top choice!

What are the advantages of using shellac?

Shellac provides clarity and a rich finish. It is made from natural materials and is simple to repair. This makes it perfect for many woodworking tasks.

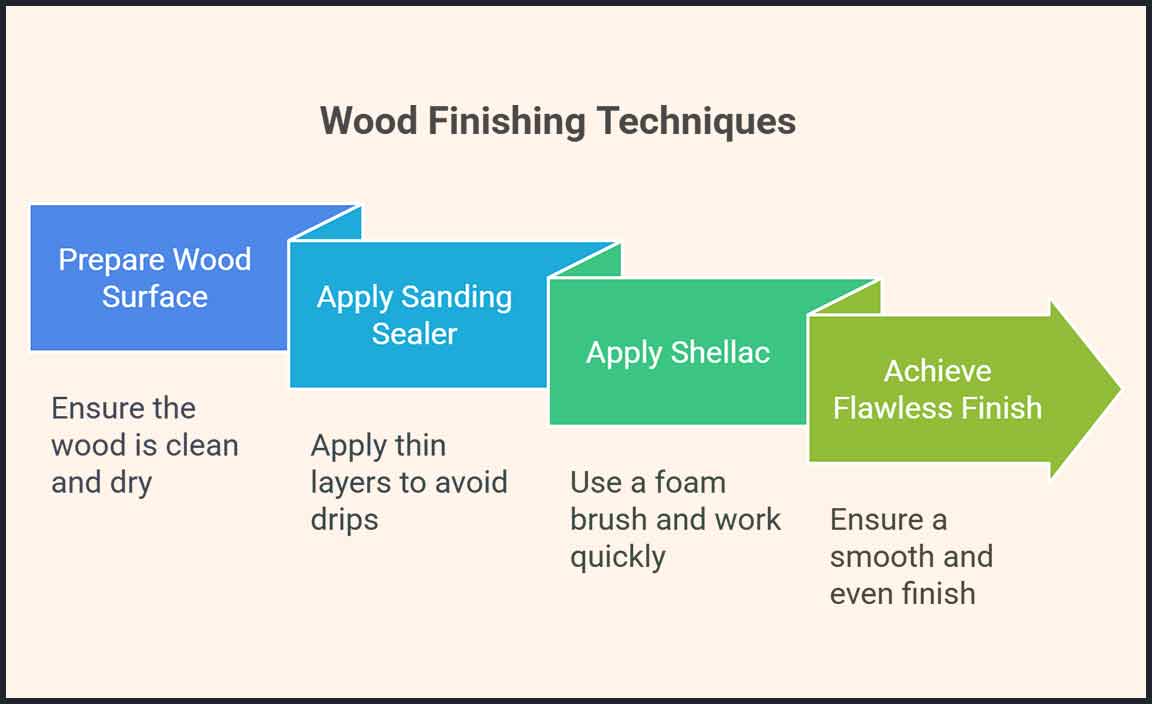

Application Techniques for Optimal Results

Best practices for applying sanding sealers on turned pieces. Techniques for achieving a flawless finish with shellac.

Applying a sanding sealer requires a gentle touch. Start with clean, dry wood and use a brush or cloth to apply thin layers. This prevents drips or runs, just like how ice cream melts neatly on a cone.

For a flawless finish with shellac, use a foam brush. Apply it quickly, then wait for it to dry. Picture a race car speeding to the finish line—don’t let it stall!

Check out the table below for quick tips:

| Technique | Tip |

|---|---|

| Sanding Sealer | Apply thin layers; avoid drips. |

| Shellac | Use a foam brush; work quickly! |

Remember, practice makes perfect. Keep experimenting until you find your best technique. Soon, your projects will shine like a star!

Choosing the Right Finish for Your Woodturning Project

Factors to consider when deciding between sanding sealer and shellac. Case studies or scenarios where one is preferred over the other.

Choosing a finish for your woodturning project can feel like picking toppings for a pizza—so many options! Sanding sealer is great for getting a smooth base, while shellac adds a shiny coat that looks sweet. Think about what you want: quick dry time or a smooth look. In a rush? Go for sanding sealer. Want a classic, warm glow? Shellac is your buddy. Check out the table below for guidance:

| Finish Type | Best For |

|---|---|

| Sanding Sealer | Quick jobs, smooth surfaces |

| Shellac | Traditional look, rich finish |

So remember, whether you’re sealing a bowl or finishing a spindle, pick what suits your project best!

Maintenance and Longevity of Finishes

Tips for maintaining projects finished with sanding sealers. Care instructions for shellacfinished items.

Taking care of your wood projects can help them shine for years. If you used a sanding sealer, keep it clean with a soft cloth. Avoid water fights; they can cause damage! For items finished with shellac, be gentle. Wipe with a damp cloth and steer clear of harsh chemicals. Remember: a little care goes a long way, just like old socks need washing!

| Finish Type | Care Tips |

|---|---|

| Sanding Sealer | Dust with a soft cloth; avoid water |

| Shellac | Wipe with a damp cloth; avoid harsh cleaners |

Common Mistakes to Avoid

Errors in applying sanding sealer and their impact on finishing. Common pitfalls with shellac and how to avoid them.

Many people make mistakes while applying sanding sealer and shellac. These errors can harm your final finish. You might use too much sealer, which causes a sticky surface. Or, you may not sand well between coats, leading to bumps. With shellac, common issues include not mixing it enough or applying it too thick. This can cause uneven color and peeling. Avoid these problems for a great finish!

What are common mistakes with sanding sealer?

The most common mistake with sanding sealer is applying too thick a layer. This can lead to a sticky finish and delays in drying.

Tips to avoid mistakes:

- Apply thin layers.

- Sand between coats.

- Use a clean brush.

- Wait for each coat to dry properly.

How to avoid mistakes with shellac?

Not mixing shellac properly is a frequent mistake. This can lead to uneven color or a rough finish.

Tips to avoid mistakes:

- Mix thoroughly before use.

- Apply in thin coats.

- Use proper tools for application.

- Practice on scrap wood first.

Conclusion

In summary, choose lathe turning sanding sealer for a durable finish that’s easy to apply. Shellac gives a warm glow but requires more care. Consider your project and what look you want. Try both finishes on scrap wood to see how they work for you. For more tips on finishes, keep reading and experimenting!

FAQs

What Are The Main Differences Between Sanding Sealer And Shellac When Used In Lathe Turning Projects?

Sanding sealer helps wood get smooth before finishing. It fills in tiny holes and makes a nice surface. Shellac is a shiny finish that makes wood look pretty. It dries fast and protects the wood. You can use both, but they serve different purposes in your project.

How Does The Drying Time Of Sanding Sealer Compare To That Of Shellac, Particularly In A Lathe Turning Context?

When you use sanding sealer, it usually takes longer to dry than shellac. Shellac dries quickly, often in just 15 minutes. Sanding sealer might take a few hours before you can touch it. If you are using a lathe to turn wood, this means you can finish quicker with shellac.

In Which Scenarios Would You Choose Sanding Sealer Over Shellac For Finishing Turned Wood Pieces?

You might choose sanding sealer when you want a smooth finish on wood. It helps fill small holes and makes the wood nice and even. Sanding sealer is easy to sand later, which helps your final coat look great. If you’re working with soft wood, sanding sealer is a good choice. Shellac can be better for different projects, but sanding sealer is great for this one!

How Do The Application Techniques Differ Between Sanding Sealer And Shellac When Finishing A Turned Object?

When you use sanding sealer, you can apply it with a brush or cloth. It goes on smoothly and fills tiny holes. After it dries, you sand it lightly to make it smooth. Shellac is different because you apply it quickly with a brush or cloth. You should use it in thin layers, and it dries fast.

What Are The Advantages And Disadvantages Of Using Sanding Sealer And Shellac Regarding The Final Appearance And Durability Of Turned Wood Items?

Using sanding sealer makes wood smooth and helps paint stick better. It dries quickly and shows the wood’s color nicely. However, it may not be very strong against wear. Shellac gives a shiny finish and is also easy to apply. But, it can wear off faster than sanding sealer, so it might not last as long.

Resource:

-

Types of wood finishes: https://www.popularwoodworking.com/finishing/types-of-wood-finishes/

-

Safe wood finishing materials: https://www.finewoodworking.com/project-guides/finishing/safe-wood-finishing-materials

-

Tips for applying wood finishes: https://www.woodmagazine.com/materials-guide/finishes/tips-for-applying-wood-finishes

-

How to repair a shellac finish: https://www.familyhandyman.com/project/how-to-repair-a-shellac-finish/