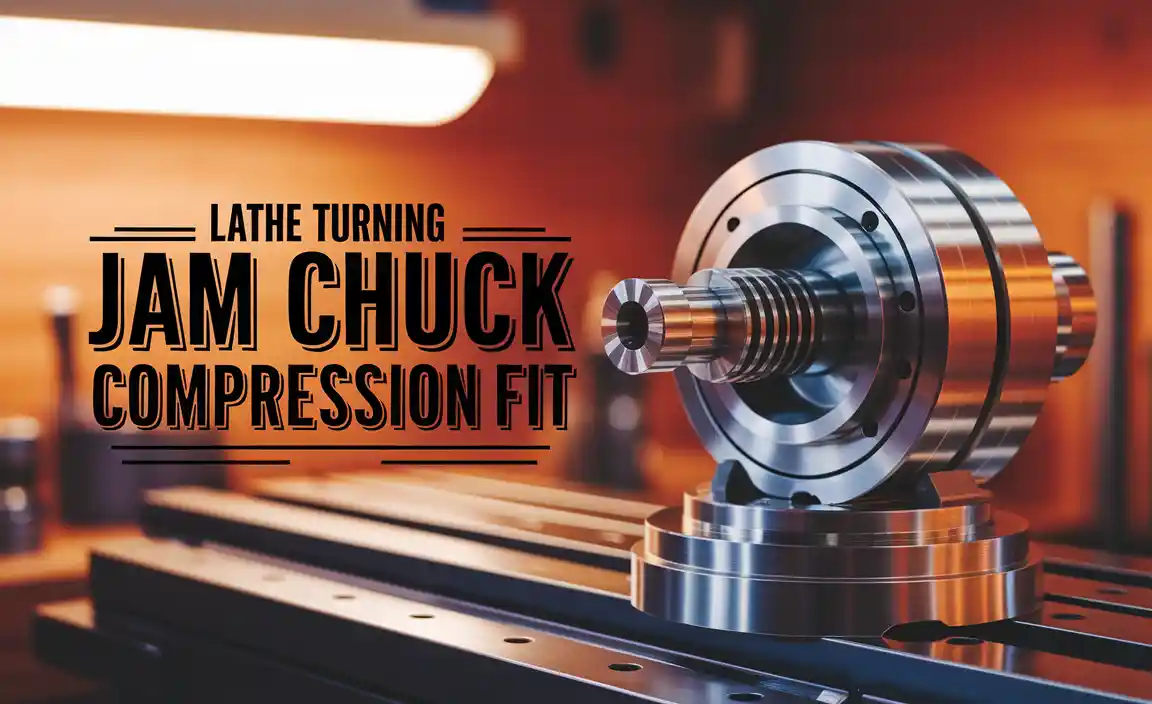

Have you ever watched a woodworking expert create amazing shapes from wood? They often use a lathe and a specialized tool. The secret to their success lies in something simple: the lathe turning tool sharpening jig setup. This handy tool helps keep their lathe tools sharp and precise.

But why is it so important to have sharp tools? Imagine trying to carve a piece of wood with a dull blade. It’s frustrating and hard work! Sharp tools make the job easier and create smoother finishes. They can even save you time.

Setting up a lathe turning tool sharpening jig isn’t just for professionals. Hobbyists can benefit, too. Whether you are a beginner or experienced, having the right setup can make your projects shine. You will feel proud of the beautiful items you create.

Ready to dive in? Let’s explore how to set up this essential jig and make your lathe turning experience much better!

Lathe Turning Tool Sharpening Jig Setup: A Complete Guide

Lathe Turning Tool Sharpening Jig Setup

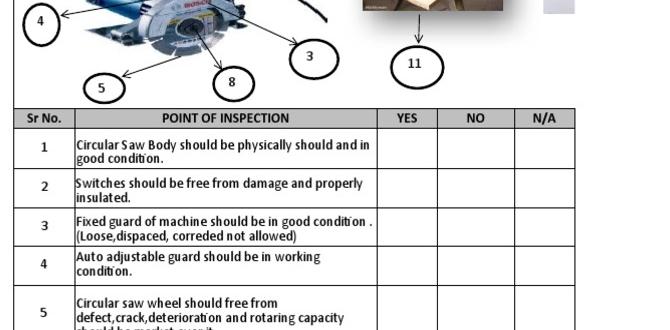

Setting up a lathe turning tool sharpening jig is essential for woodworkers. A well-sharpened tool makes crafting easier and safer. Imagine trying to carve a masterpiece with a dull chisel—frustrating, right? Our guide covers simple steps to set up your jig correctly. You’ll learn how to find the right angle for sharpening and the importance of maintaining a consistent edge. With these tips, you’ll enhance your craftsmanship and enjoy woodworking even more!Understanding Lathe Turning Tools

Types of lathe turning tools and their uses. Importance of tool sharpness for effective turning.Lathe turning tools are like the magic wands of woodworking! There are several types, each with its own special job. For instance, gouges are fantastic for carving, while chisels are great for shaping edges. A sharp tool is a happy tool! Keeping your tools sharp helps them perform better and last longer. If they’re dull, think of them as trying to cut a sandwich with a butter knife—frustrating, right? It’s key to keep them in tip-top shape for smooth and safe turning.

| Tool Type | Use |

|---|---|

| Gouge | Carving shapes |

| Chisel | Shaping edges |

| Parting Tool | Creating narrow cuts |

| Skew Chisel | Finishing surfaces |

Choosing the Right Sharpening Jig

Features to look for in a sharpening jig. Comparison of manual vs. automated sharpening jigs.Finding the perfect sharpening jig is a bit like dating. You want the right features to make things smooth! Look for a jig that offers easy adjustments and solid stability. These features help you sharpen tools quickly and precisely.

There are two main types: manual and automated jigs. Manual jigs are great for hands-on folks who like to feel the grind. Meanwhile, automated jigs do the hard work, so you can sit back and sip your coffee. Below is a simple comparison:

| Feature | Manual Jigs | Automated Jigs |

|---|---|---|

| User Control | High | Low |

| Speed | Medium | High |

| Consistency | Varies | Very High |

In short, choose a manual jig for control and an automated one for speed. It all depends on your style! And remember, a good sharpening jig can make your tools sharper than your jokes!

Setting Up Your Sharpening Jig

Stepbystep guide to assembling the jig. Adjustments and calibrations for optimal performance.Getting your sharpening jig ready is like preparing for a fun art project. First, gather all the parts on a clean table. It’s kind of like a puzzle! Next, follow the simple steps below:

| Step | Description |

|---|---|

| 1 | Connect the base to the frame. Make it sturdy! |

| 2 | Attach the sharpening arm. Check it’s well-secured! |

| 3 | Set your angle. A bit of math—don’t panic! |

| 4 | Calibrate for perfect sharpness. No one likes dull tools! |

Make adjustments carefully. It’s like tuning a guitar! The right setup helps keep your tools sharp and ready for action. Remember, a shiny edge is a happy edge!

Sharpening Techniques for Lathe Tools

Different sharpening angles and their effects. Techniques for various tool profiles.Sharpening lathe tools is crucial for better performance. Different angles affect how the tool cuts. For example, a sharp angle makes a finer cut, while a wide angle is better for rough work. Techniques vary by tool shape. Here are some key sharpening angles and their uses:

- 30 degrees: Good for a smooth finish.

- 45 degrees: Great for shaping wood.

- 60 degrees: Best for cutting sharp corners.

Each tool profile needs its own sharpening method. Knowing these can help you work more efficiently!

What is the best sharpening angle for lathe tools?

The best angle often depends on the tool type. For instance, a skew chisel works well at a 30-degree angle for smooth cuts. Choosing the right angle enhances your tool’s performance and extends its life.

Maintaining Your Sharpening Jig

Regular maintenance tips for longevity. Troubleshooting common issues.To keep your sharpening jig in top shape, regular checks are essential. Clean the jig after each use to prevent debris buildup. A quick wipe-down can work wonders—like a spa day for tools! If you face wobbling or uneven sharpening, double-check the alignment. Tighten loose screws; they can be sneaky little troublemakers. Also, poking around for rust? A little oil goes a long way in keeping everything smooth!

| Maintenance Tip | Action |

|---|---|

| Clean after use | Wipe down |

| Check alignment | Tighten screws |

| Prevent rust | Apply oil |

Advanced Sharpening Strategies

Techniques for achieving razorsharp edges. Incorporating honing and polishing for perfection.Creating razor-sharp edges requires skill and attention. Start with a good sharpening jig. Use the right angle for your tools. After sharpening, honing brings a finer edge. This step involves using a whetstone or a fine file. Then, polish the edge for a smooth finish. Polishing helps reflect light, showcasing your work. These steps turn a simple tool into a precision instrument.

How can honing improve sharpening?

Honing sharpens edges further and removes tiny burrs left after sharpening. It helps the tool cut better and lasts longer.

Tips for Honing and Polishing:

- Choose the right honing tool.

- Apply even pressure while honing.

- Use a polishing compound after honing.

- Test the sharpness carefully.

Real-world Applications of Sharpened Tools

Benefits of using sharpened tools in projects. Case studies of improved turning results with sharp tools.Using sharpened tools can make a big difference in projects. They help you cut and shape materials smoothly. This means less work and better results. For example, one woodworker improved their work by 30% with sharp tools. Here are some benefits:

- Better accuracy: Sharp tools cut cleaner and more precisely.

- Less effort: You use less force, making the task easier.

- Faster projects: Complete tasks quickly with less strain.

Many people see a huge improvement when they use a lathe turning tool sharpening jig setup. Sharp tools can change everything in your work!

Why are sharpened tools so important?

Sharpened tools provide greater control, resulting in cleaner and smoother finishes in your projects.

Benefits of using sharpened tools

- Improved safety

- Higher-quality results

- Extended tool life

Frequently Asked Questions about Tool Sharpening

Common queries and expert answers. Tips for beginners and experienced woodturners alike.Many new and seasoned woodturners often have questions about tool sharpening. Here are some common queries with helpful answers:

What is the best way to sharpen tools?

The best way to sharpen tools is to use a sharpening jig for precision and control. This makes sure your tools stay sharp and last longer.

How often should I sharpen my tools?

You should sharpen your tools before each major project or after using them for a while. This keeps them effective and safe to use.

Tips for beginners:

- Start with a simple sharpening jig.

- Practice on inexpensive tools first.

Expert advice:

- Check your tool’s edge regularly.

- Use different grits for finer sharpening.

Sharpening can seem tricky, but with practice, it becomes easy!

Conclusion

In summary, setting up a lathe turning tool sharpening jig is essential for effective woodturning. It keeps your tools sharp and precise, making your work easier. Remember to take your time during setup for the best results. You can further explore detailed guides or videos online to improve your skills. Get started on your sharpening journey today!FAQs

What Are The Essential Components Of A Lathe Turning Tool Sharpening Jig Setup?To set up a lathe turning tool sharpening jig, you need a few important parts. First, you’ll need a sturdy base to keep everything steady. Then, you need a guide to hold the tool and keep it at the right angle. Don’t forget a grinding wheel or sharpener to actually sharpen the tool. Finally, some clamps will help hold the tool in place while you work.

How Do You Calibrate The Sharpening Angle For Different Lathe Tools Using The Jig?To calibrate the sharpening angle for different lathe tools, first, choose the tool you want to sharpen. Next, set the jig to the angle needed for that specific tool. You can find the right angle in the tool’s instructions. Then, place the tool in the jig and adjust it until it matches the angle. Finally, tighten it down and start sharpening!

What Materials Are Best Suited For Constructing A Diy Lathe Tool Sharpening Jig?To build a DIY lathe tool sharpening jig, you’ll need some simple materials. Start with a sturdy piece of wood for the base. You can use metal rods or pipes to create the arm that holds the tool. A small clamp can help keep everything in place. Finally, add a set of wheels or a sliding mechanism to help adjust the angle easily.

What Safety Precautions Should Be Taken When Sharpening Lathe Tools With A Jig Setup?When you sharpen lathe tools with a jig, always wear safety goggles to protect your eyes. Keep your hands away from moving parts and the sharp edge. Make sure the jig is set up correctly before you start. Use a sturdy workbench to avoid accidents. If you’re not sure, ask for help from an adult.

How Often Should Lathe Turning Tools Be Sharpened, And What Signs Indicate That Sharpening Is Needed?You should sharpen lathe turning tools often, maybe after every few hours of use. If you notice the tool is cutting slowly, or it leaves rough edges, it’s time to sharpen. Also, if you hear a high-pitched noise when cutting, that is a sign. Keeping tools sharp helps make your work easier and safer!