Have you ever wondered how a metal lathe works? This amazing machine can shape metal into precise parts. But what makes it run smoothly? A big part of the answer lies in lathe wiring and understanding torque.

Think about your favorite toy. When it breaks, you want to fix it quickly. Likewise, metal lathes need proper wiring to prevent breakdowns. With the right setup, they can spin quickly and accurately. This is where torque comes in.

Torque is the force that turns the lathe. It helps the tool cut through metal like a hot knife through butter. This power can make or break a project. Do you want your projects to come out perfectly? Then, let’s dive into the details of lathe wiring and how torque plays a key role in your metalworking adventures.

Lathe Wiring: Understanding Metal Lathe Torque Essentials

Lathe Wiring Metal Lathe Torque

Lathe wiring is essential for proper operation. Connecting a metal lathe correctly ensures it operates at optimal torque. Did you know that incorrect wiring can lead to motor damage? Understanding torque is vital for achieving precise cuts and shapes in metalworking. It’s like tuning an instrument; only then will it produce great results. Knowing the basics of lathe wiring can elevate your projects and avoid common mistakes. Happy turning!Types of Metal Lathes and Their Wiring Needs

Variations between manual and CNC metal lathes. Specific wiring requirements for different lathe models.Metal lathes come in two main types: manual and CNC. Manual lathes let the operator control the machine directly. They are simple and great for learning. CNC lathes use computers to guide the tool. They are faster and can make precise cuts. Each model requires different wiring setups. Proper wiring ensures safety and proper function. It is vital to follow the specific wiring needs of each lathe type for the best performance.

What are the wiring needs for different lathe models?

Different lathe models have unique wiring requirements. It’s best to refer to manuals for specific diagrams. Here are some examples:

- Manual Lathes: Basic wiring for on/off switches and motors.

- CNC Lathes: Advanced wiring for computers and control systems.

- Hybrid Models: Combination of manual features with CNC automation.

Torque Requirements in Metal Lathes

Definition of torque in the context of metal lathes. How torque affects lathe operation and quality of work.Torque is like the muscle of a metal lathe. It’s the force that helps the machine spin and shape metal. Without enough torque, a lathe can struggle to do its job properly, just like when you try to push a heavy door that’s stuck. More torque can lead to better quality work and smoother operations. Think of it as your lathe’s morning coffee—without it, things just don’t move as smoothly! So, ensuring the right torque is crucial for making those metal pieces shine.

| Torque Effect | Lathe Operation | Quality of Work |

|---|---|---|

| Low Torque | Struggles to cut | Poor finish |

| Optimal Torque | Smooth operation | High precision |

Essential Tools and Materials for Lathe Wiring

List of tools required for wiring a metal lathe. Recommended materials for electrical connections and insulation.Wiring a metal lathe needs some special tools and materials. First, grab the basics like wire strippers, pliers, and screwdrivers. You’ll need connectors and terminals for those vital electrical links. Insulation tape? Don’t forget that! It’s like giving your wires a cozy blanket. Here’s a handy table to keep track:

| Tools | Recommended Materials |

|---|---|

| Wire Strippers | Electrical Tape |

| Pliers | Solder |

| Screwdrivers | Heat Shrink Tubing |

| Multimeter | Wire Connectors |

These tools make wiring smoother than a freshly polished lathe! You want everything to connect snugly, so quality is key. Remember, no one wants a short circuit ruining your fun. Grab these essentials, and you’re one step closer to being a wiring wizard!

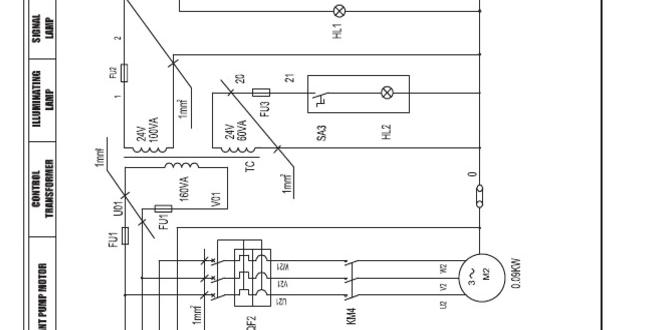

Step-by-Step Guide to Wiring a Metal Lathe

Detailed wiring instructions for common metal lathe setups. Common mistakes to avoid during the wiring process.Wiring a metal lathe is easy if you follow the right steps. Start by checking your lathe’s manual for specific instructions. Connect the power source to the motor. Make sure all wires are secure. Remember, always double-check your connections. Common mistakes include:

- Not using the correct wire gauge

- Forgetting to disconnect power when working

- Mixing up positive and negative connections

Take your time to avoid these errors for a smooth setup!

What should I know about metal lathe wiring?

Understanding metal lathe torque is important. Torque affects how well your lathe will work. Too much torque can harm your machine. Always ensure your settings are just right!

Testing and Troubleshooting Lathe Wiring

Techniques for testing electrical connections in lathes. Common wiring issues and solutions.Testing your lathe wiring can feel like a puzzle, but it’s easier than it sounds! First, check those electrical connections with a multimeter. It’s like a superhero for catching faults! Common issues include loose wires or damaged insulation. If you find a problem, reconnected wires can save the day. Here’s a quick guide in case you need it:

| Issue | Solution |

|---|---|

| Loose Connections | Tighten the screws and connectors. |

| Frayed Wires | Replace or repair the damaged wires. |

| Burnt Fuses | Replace the fuse with the correct rating. |

Remember, safe lathing keeps everything turning smoothly, and hey, if wiring tests were a game, you’d be the champ!

Upgrading and Modifying Lathe Wiring for Increased Torque

Best practices for enhancing wiring for higher torque applications. Considerations for component upgrades.To boost your lathe’s torque, start with the wiring. Use quality wiring that can handle higher currents. Upgrade components like the motor and power supply for better performance. Take these steps into account:

- Choose thicker wires for less resistance.

- Opt for a stronger motor with high torque ratings.

- Use connectors designed for heavy loads.

These changes will help you improve your lathe’s torque and efficiency.

What upgrades help increase torque in a lathe?

To increase torque, upgrade to a stronger motor, change to thicker wires, and use reliable connectors. These simple improvements can make your lathe work much better!

Safety Tips When Working with Lathe Wiring

Key safety precautions to prevent electrical hazards. Proper handling of tools and working with live circuits.Keeping safe while working with lathe wiring is very important. Here are some key precautions:

- Always disconnect power before making adjustments.

- Wear safety goggles and gloves to protect your eyes and hands.

- Keep tools in good condition to avoid accidents.

- Never touch live wires or circuits with wet hands.

- Stay alert and avoid distractions while working.

Following these tips can help prevent electrical hazards. Stay safe and enjoy your projects!

What should I do to ensure safety with lathe wiring?

Always disconnect power before working. This simple step prevents electrical shocks. Remember to wear protective gear, like gloves and goggles, to keep yourself safe. Keeping your workspace tidy also avoids accidents.

Resources for Further Learning on Lathe Wiring

Recommended books, websites, and videos on lathe wiring. Community forums and expert resources for troubleshooting and advice.Learning about lathe wiring can be exciting! Here are some great resources to help you:

- Books: Check out “Metal Lathe Basics” for a solid foundation.

- Websites: Visit popular sites like Instructables for easy guides.

- Videos: YouTube has many tutorials that are fun to follow.

- Forums: Join communities like Reddit’s r/metalworking to ask questions.

- Expert Resources: Seek advice from local workshops or classes.

These tools will help you learn and troubleshoot as you explore lathe wiring!

What are some beginner-friendly videos for lathe wiring?

Look for channels like “This Old Tony” or “NYC CNC” for clear, beginner-friendly videos. They cover steps and tricks that make learning easier.

Conclusion

In summary, understanding lathe wiring and torque is essential for safe operation. Proper wiring ensures your metal lathe runs smoothly. Torque affects how well the lathe cuts materials. We encourage you to practice safe wiring techniques and learn more about torque settings. Exploring these topics will make you a better machinist. Keep experimenting and have fun with your projects!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Wiring, Specifically Focusing On Metal Lathes And Torque:Sure! Here are some questions about lathe wiring and torque on metal lathes. 1. How does a metal lathe work? A metal lathe spins a piece of metal. You can shape it using cutting tools. 2. What is torque? Torque is the turning force that makes something spin faster or slower. It helps the lathe cut better. 3. Why is wiring important for a lathe? Wiring gives power to the lathe. Without it, the lathe can’t work. 4. How do we connect the lathe to power? We plug the lathe into an electrical outlet. Some lathes need special wiring. 5. What happens if the wires are broken? If the wires are broken, the lathe won’t work. You need to fix the wires to use it again.

Sure! Please provide the question you’d like me to answer.

What Type Of Electrical Specifications Are Required For Wiring A Metal Lathe To Ensure Optimal Torque Performance?To wire a metal lathe for the best torque, you need to know a few things. First, use the right voltage, usually 220 volts for most lathes. Next, check the amperage rating, which shows how much power the lathe needs. You should also use thick wires that can handle the power without getting hot. Finally, make sure to have safety features, like circuit breakers, to protect the lathe and you.

How Does Motor Torque Directly Impact The Machining Capabilities And Accuracy Of A Metal Lathe?Motor torque is the strength that helps the metal lathe spin the metal. Higher torque means the lathe can cut through harder metals more easily. If the torque is low, the machine may struggle and make mistakes. This can lead to poor shapes or sizes in the final product. So, more torque helps us make better and more precise parts.

What Are The Common Electrical Wiring Configurations For Controlling The Torque Of A Metal Lathe Motor?To control the torque of a metal lathe motor, you can use a few common wiring setups. One is the three-phase system, which uses three wires to provide power. Another is a variable frequency drive (VFD), which changes the motor’s speed. You can also use relays to switch the power on and off. These setups help you manage how hard the motor works.

How Can Improper Wiring Affect The Torque Output Of A Metal Lathe And Potentially Harm The Machine?Improper wiring can cause power problems for a metal lathe. This may reduce its torque, which makes it harder to turn metal pieces. If the lathe doesn’t get enough power, it can overheat. This overheating can damage the machine and make it work poorly. So, correct wiring is very important!

What Are The Best Practices For Troubleshooting Torque-Related Issues In The Wiring System Of A Metal Lathe?To fix torque problems in a metal lathe’s wiring, first, check all wires for damage. Make sure connections are tight and secure. You should also look at the power source to ensure it works properly. If something seems wrong, test the motor, too. Finally, consult the machine’s manual for specific guidance.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Wiring, Specifically Focusing On Metal Lathes And Torque:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are some questions about lathe wiring and torque on metal lathes. 1. How does a metal lathe work? A metal lathe spins a piece of metal. You can shape it using cutting tools. 2. What is torque? Torque is the turning force that makes something spin faster or slower. It helps the lathe cut better. 3. Why is wiring important for a lathe? Wiring gives power to the lathe. Without it, the lathe can’t work. 4. How do we connect the lathe to power? We plug the lathe into an electrical outlet. Some lathes need special wiring. 5. What happens if the wires are broken? If the wires are broken, the lathe won’t work. You need to fix the wires to use it again.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Type Of Electrical Specifications Are Required For Wiring A Metal Lathe To Ensure Optimal Torque Performance?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To wire a metal lathe for the best torque, you need to know a few things. First, use the right voltage, usually 220 volts for most lathes. Next, check the amperage rating, which shows how much power the lathe needs. You should also use thick wires that can handle the power without getting hot. Finally, make sure to have safety features, like circuit breakers, to protect the lathe and you.”}},{“@type”: “Question”,”name”: “How Does Motor Torque Directly Impact The Machining Capabilities And Accuracy Of A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Motor torque is the strength that helps the metal lathe spin the metal. Higher torque means the lathe can cut through harder metals more easily. If the torque is low, the machine may struggle and make mistakes. This can lead to poor shapes or sizes in the final product. So, more torque helps us make better and more precise parts.”}},{“@type”: “Question”,”name”: “What Are The Common Electrical Wiring Configurations For Controlling The Torque Of A Metal Lathe Motor?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To control the torque of a metal lathe motor, you can use a few common wiring setups. One is the three-phase system, which uses three wires to provide power. Another is a variable frequency drive (VFD), which changes the motor’s speed. You can also use relays to switch the power on and off. These setups help you manage how hard the motor works.”}},{“@type”: “Question”,”name”: “How Can Improper Wiring Affect The Torque Output Of A Metal Lathe And Potentially Harm The Machine?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Improper wiring can cause power problems for a metal lathe. This may reduce its torque, which makes it harder to turn metal pieces. If the lathe doesn’t get enough power, it can overheat. This overheating can damage the machine and make it work poorly. So, correct wiring is very important!”}},{“@type”: “Question”,”name”: “What Are The Best Practices For Troubleshooting Torque-Related Issues In The Wiring System Of A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To fix torque problems in a metal lathe’s wiring, first, check all wires for damage. Make sure connections are tight and secure. You should also look at the power source to ensure it works properly. If something seems wrong, test the motor, too. Finally, consult the machine’s manual for specific guidance.”}}]}