Have you ever watched a metal lathe spin? It’s fascinating how it shapes metal with precision. But how does it hold that metal securely? This is where lathe workholding comes in. Proper workholding techniques make all the difference in creating quality parts.

Imagine trying to carve a masterpiece from a block of ice without a proper grip. It would slip and slide everywhere! Just like that ice, metal pieces need to be held tight while the lathe works its magic. A well-designed gear train makes this possible.

Did you know that the gear train helps control the lathe’s speed and power? Without it, the machine wouldn’t function as it should. Understanding how to set up your lathe with the right workholding tools can elevate your metalworking skills.

This article will explore the key aspects of lathe workholding, the gear train, and their roles in ensuring safety and precision. Are you ready to discover the secrets behind your metal lathe?

Lathe Workholding: Understanding Metal Lathe Gear Train Dynamics

Lathe Workholding and Metal Lathe Gear Train

Lathe workholding is crucial for machining. Without proper workholding, your piece might slip or vibrate. This can ruin your project. Did you know that a gear train in a metal lathe helps control the speed and torque? It allows for precise cuts and smoother operations. Understanding how these parts work together can make a big difference in your lathe projects. So, are you ready to take your lathe skills to the next level?What is a Lathe Gear Train?

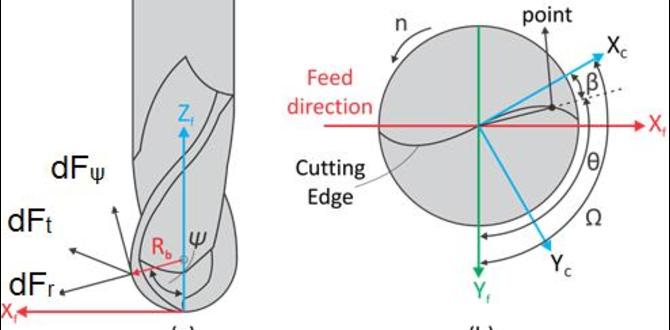

Definition and function of a gear train in a lathe. Types of gear trains commonly used in metal lathes.A gear train in a lathe links gears to control speed and torque. It allows the lathe to spin at different rates, making it useful for various tasks. Common types include:

- Simple gear trains: These have two gears. They are easy to understand and use.

- Compound gear trains: They use more than two gears. They can change speeds more effectively.

- Planetary gear trains: They have gears moving around a central gear. This design is compact and very efficient.

What is the function of a gear train in a lathe?

The function of a gear train is to adjust the speed and power of the lathe. This helps in shaping and cutting metal accurately. Different gear trains give various advantages depending on the job at hand.

Importance of Workholding in Lathe Operations

Explanation of workholding and its significance in precision machining. Common challenges faced in workholding during lathe operations.Workholding is a crucial part of lathe operations. It keeps the metal piece steady while shaping it. This precision helps create accurate and high-quality parts. Without proper workholding, machines may produce mistakes. Common challenges include:

- Pieces slipping during operation

- Inconsistent pressure on the material

- Misalignment affecting shape

These issues can lead to wasted time and material. Good workholding keeps things running smoothly. Using the right tools makes a big difference!

What are the benefits of good workholding?

Good workholding increases accuracy, reduces waste, and enhances safety in lathe operations.

Factors to Consider When Choosing Workholding Devices

Material compatibility and workpiece size considerations. Precision and repeatability needs in lathe workholding.Choosing the right workholding device is like picking the best seat at a concert—you want the right fit! Start by checking material compatibility; some materials are as picky as cats. Next up is workpiece size; make sure your device can handle it. Size matters! Precision and repeatability are key, too. You don’t want your project to look like a wobbly table, right? Here’s a quick look:

| Factor | Consideration |

|---|---|

| Material | Fit for purpose |

| Size | Match your workpiece |

| Precision | Tight tolerances needed |

Choose wisely, and you’ll keep your work smooth and your projects happy!

Understanding Gear Train Configurations

Breakdown of common gear train setups in metal lathes. Influence of gear ratios on machining processes.Many metal lathes use different gear train setups. Each gear arrangement can affect how a machine works. Here are some common configurations:

- Simple Gear Train: Easy to use and understand.

- Compound Gear Train: Offers many speed options.

- Serviceable Gear Train: Smooth and reliable for tasks.

The gear ratios also play an important role. Higher ratios mean more torque, useful for heavy cutting. Lower ratios help with precision machining. Understanding these setups helps you work better with metal lathes!

How do gear ratios affect machining?

Gear ratios determine how fast and powerful the lathe can cut materials. Higher ratios give more strength, while lower ratios provide more control.Best Practices for Setting Up Lathe Workholding

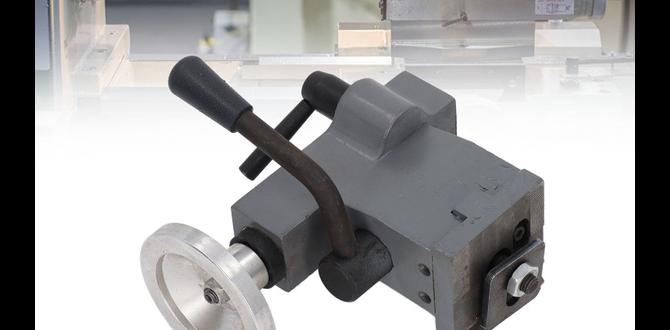

Stepbystep guide to secure workholding setup. Tips for ensuring accuracy and stability during machining.To set up your lathe workholding properly, follow these simple steps. First, clean the lathe and remove any debris. Next, choose the right chuck or fixture for your workpiece. Position the workpiece securely, ensuring it’s not wobbling like your uncle on the dance floor. Tighten everything evenly to keep it stable. Remember, stability means accuracy. A secure piece helps achieve smooth cuts and perfect shapes.

| Steps | Tips |

|---|---|

| Clean the lathe | Keep it tidy to avoid errors. |

| Select the right chuck | Match it to your workpiece. |

| Position and secure | Tighten evenly for balance. |

| Check for wobble | Before you start, give it a gentle shake. |

Following these tips can improve your machining game. Remember, a well-set lathe is like a well-packed suitcase—everything has its place!

Maintenance Tips for Gear Trains in Metal Lathes

Common issues with gear trains and how to address them. Regular maintenance practices for optimal lathe performance.Gear trains in metal lathes can be tricky little creatures. Common issues include wear and tear, causing slippage or noise. To tackle these problems, check for any loose screws or worn-out gears. Regular maintenance is key for keeping your lathe happy. Clean the gears often and lubricate them well. Think of it like giving your lathe a nice spa day! Here are a few tips:

| Maintenance Task | Frequency | Tip |

|---|---|---|

| Check for wear | Monthly | Inspect gears for cracks. |

| Lubrication | Every 500 hours | Use the correct oil. |

| Clean gears | Weekly | Remove dust and debris. |

With these tips, your gear train will run smoother than a hot knife through butter!

Advanced Techniques in Lathe Workholding

Innovative workholding solutions for complex machining tasks. Future trends in lathe workholding technologies.Innovative solutions are changing how we hold workpieces on lathes. For tricky shapes, magnetic and vacuum systems are popular. These tools grip well without a fuss! In the future, we may see smart workholding that uses sensors. They can improve accuracy and speed. Imagine a lathe that adjusts itself while you sip your coffee. Now that’s a dream come true!

| Technique | Benefit |

|---|---|

| Magnetic Holders | Great for smooth surfaces! |

| Vacuum Systems | No scratches or marks! |

| Sensor Integration | Adjusts on its own! |

Conclusion

In conclusion, understanding lathe workholding and gear trains is essential for effective metal lathe operation. Proper workholding ensures safety and accuracy. Gear trains help control speeds and torque, making your projects smoother. To improve your skills, practice using different workholding methods and explore gear train designs. Keep learning and experimenting to become a better lathe operator!FAQs

What Are The Different Types Of Workholding Methods Commonly Used In Metal Lathe Operations, And How Do They Affect Workpiece Stability?In metal lathes, we use different ways to hold the metal pieces. Common methods include chucks, collets, and clamps. A chuck grips the workpiece tightly with metal jaws. Collets are special tubes that hold smaller pieces securely. These methods help keep the workpiece stable, so it doesn’t move around, which is important for making precise cuts.

How Does The Gear Train In A Metal Lathe Contribute To The Precision Of Machining Operations?The gear train in a metal lathe helps us turn materials very accurately. It connects different parts of the lathe so they move together smoothly. This teamwork makes sure the tool cuts in a straight line. When everything works well, we get better and cleaner results. That means our projects look great and fit perfectly!

What Are The Advantages And Disadvantages Of Using A Three-Jaw Chuck Versus A Four-Jaw Chuck In Lathe Workholding?A three-jaw chuck holds round objects tightly and works quickly. It’s easy to use and saves time. However, it can’t hold odd shapes well. A four-jaw chuck is better for strange shapes and can hold things firmly too, but it takes more time to set up. So, for round things, use three jaws; for tricky shapes, use four jaws.

How Can One Determine The Appropriate Gear Ratios In A Lathe’S Gear Train For Various Machining Tasks?To pick the right gear ratios for a lathe, you first think about what you want to make. Different tasks need different speeds. You can check the lathe’s manual for gear options or ratios. Adjust the gears to get the speed or power that matches your task. Practice helps you learn which setups work best for you!

What Safety Precautions Should Be Taken When Setting Up Workholding Systems And Adjusting The Gear Train In A Metal Lathe?When setting up the workholding system on a metal lathe, always wear safety goggles to protect your eyes. Make sure your hair and loose clothing are secured so they won’t get caught in the machine. Before starting the lathe, double-check that all tools are properly placed and that nothing is in the way. When adjusting the gear train, turn off the lathe first to avoid any accidents. Lastly, keep your hands away from moving parts to stay safe.