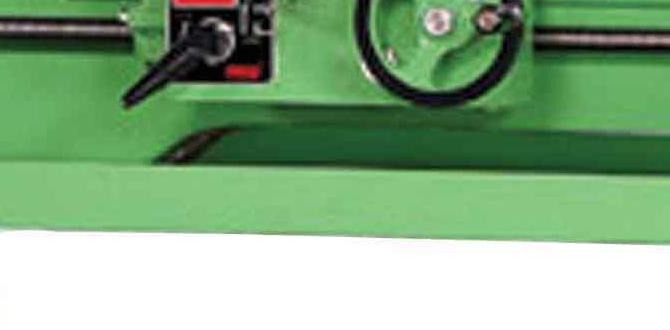

Have you ever watched a metal lathe in action? It’s fascinating! This machine shapes metal with precision. But did you know that how you hold the metal is just as important as the cutting itself? This is where lathe workholding comes into play.

Picture this: You are working on a project using a lathe. Your metal part slips, and all your hard work goes down the drain. Frustrating, right? Proper workholding keeps your metal pieces secure during the shaping process. It helps you achieve neat and accurate results.

In this article, we will explore the different lathe workholding techniques and the parts involved. Each part has a role in keeping your project on track. From chucks to clamps, understanding these components makes you a better machinist. Ready to dive in?

Effective Lathe Workholding For Metal Lathe Parts

Lathe Workholding and Metal Lathe Parts

Lathe workholding involves securing metal pieces so they can be shaped accurately. Without the right workholding tools, your projects can go wrong. Did you know that a simple clamp can make a big difference in precision? Different metal lathe parts, like chucks and tailstocks, help in keeping everything stable. By understanding these components, you can create better pieces and enjoy the process more. So, are you ready to improve your lathe skills?Essential Parts of a Metal Lathe

Detailed description of key components: bed, headstock, tailstock, carriage. Functionality and roles of each part in lathe operations.Every metal lathe has key parts that work together smoothly. The bed holds everything steady and flat. The headstock drives the spindle to spin the material. The tailstock supports the other end, helping with precision. The carriage moves the cutting tool and holds it in place. Each piece plays a big role in making accurate cuts while creating parts.

What are the main parts of a metal lathe?

The main parts of a metal lathe include:

- Bed: Provides support and stability.

- Headstock: Drives the spindle for rotation.

- Tailstock: Holds the workpiece securely.

- Carriage: Moves the cutting tool smoothly.

Types of Workholding Devices

Comparison of chucks, collets, and vises used in lathe workholding. Advantages and disadvantages of each workholding device type.In the world of lathe workholding, three stars shine bright: chucks, collets, and vises. Each has its own charm and quirks. Chucks are popular for their grip, holding larger pieces snug as a bug. Collets, however, love smaller items and offer tight-fitting hugs. Vises are like the strong friends; they hold things still, but sometimes they can be a bit too clumsy. Here’s a quick glance at their strengths and weaknesses:

| Device | Advantages | Disadvantages |

|---|---|---|

| Chuck | Versatile, great for big items | Can slip with small pieces |

| Collet | Precision hold, tight fit | Limited sizes, can be pricey |

| Vise | Sturdy, excellent for stability | Oftentimes bulky, may be overkill |

Choose wisely, and your metal lathe parts will thank you with a smile (and maybe even a shiny finish)!

Choosing the Right Workholding Solution

Factors to consider when selecting workholding systems for specific tasks. Impact of material, size, and shape on workholding choices.Choosing the perfect workholding system is key to a smooth lathe experience. First, think about the material. Metal behaves differently than wood, so pick accordingly. Next, consider the size and shape of your part. A big, round piece needs a different hold than a tiny, square one. Imagine trying to hold a slippery fish in your hands—now, that’s tricky! Use the right tools to keep everything steady and safe.

| Factor | Importance |

|---|---|

| Material | Determines grip type and force needed |

| Size | Affects stability and holding method |

| Shape | Impacts workholding method and tool access |

Setup and Alignment Techniques

Best practices for setting up workholding devices on a lathe. Importance of alignment and its effect on machining accuracy.Setting up workholding devices on a lathe is crucial for great performance. First, make sure everything is clean. Dirt can ruin your amazing plans! Next, adjust the workholding device carefully. If you’re off a little bit, your final piece could end up looking like a wobbly jelly. Proper alignment ensures your measurements are spot-on, leading to better results. Remember, a happy lathe means a happy maker!

| Best Practices for Setup | Effects of Alignment |

|---|---|

| Clean surfaces before setup | Improves machining accuracy |

| Use the right tools | Reduces errors |

| Check for level | Makes shaping parts easier |

In fact, studies show that proper alignment can boost accuracy by up to 50%. So, don’t skip those steps! Following these tips will keep your lathe running as smooth as butter on hot toast.

Common Issues and Troubleshooting

Identification of frequent workholding problems and their causes. Solutions and preventative measures to minimize lathe workholding issues.Many folks face issues with workholding when using a lathe. Common problems include parts slipping or not staying still. This usually happens due to loose clamps or poor setups. Want to avoid mishaps? Make sure everything is tight before starting. Check your tools too! A worn tool can lead to bad results. Here’s a quick checklist to help:

| Problem | Cause | Solution |

|---|---|---|

| Part slips | Loose clamps | Tighten everything! |

| Uneven cuts | Poor tool condition | Sharpen or replace tools. |

Keep your lathe clean and inspect it regularly. Remember, a little TLC goes a long way!

Best Practices for Maintenance and Care

Guidelines for maintaining workholding devices to prolong lifespan and efficiency. Practical tips for ensuring accurate performance of metal lathe parts.Taking care of your workholding devices is crucial for keeping them in tip-top shape! Here are some easy tips to help maintain those metal lathe parts. Clean them regularly to keep grime at bay. Use the right lubricants – it’s not the same as spreading peanut butter! Check for wear and tear often; after all, you wouldn’t want a rusty hunk of metal ruining your masterpiece. Proper storage keeps them safe and sound, too.

| Practice | Description |

|---|---|

| Clean Regularly | Remove dirt and dust to ensure smooth operation. |

| Use Proper Lubricants | Keep parts moving freely without sticky messes. |

| Check for Damage | Inspect for wear to catch issues before they worsen. |

| Store Safely | Protect parts from dust and accidental damage. |

By following these guidelines, you’ll get the most out of your lathe and workholding devices. So, treat them well, and they’ll keep spinning the good stuff!

Conclusion

In conclusion, lathe workholding is essential for shaping metal parts accurately. By knowing the right tools and techniques, you can achieve great results. Always choose the right workholding solutions for your projects. For more tips and details, we encourage you to keep exploring resources on metal lathe parts. Practice makes perfect, so start working on your next project today!FAQs

Certainly! Here Are Five Related Questions On The Topic Of Lathe Workholding And Metal Lathe Parts:Sure! When using a lathe, workholding means keeping the metal piece steady while we shape it. We can use different tools like chucks or vises to hold our metal. These tools help us get accurate shapes and sizes. Always make sure everything is tight before starting. This keeps our work safe and look great!

Sure! Just ask your question, and I’ll be happy to help you out.

What Are The Different Types Of Workholding Devices Used In Metal Lathe Operations, And How Do They Affect Precision Machining?In metal lathe operations, we use different workholding devices to hold metal pieces in place. Some common types are chucks and collets. A chuck grabs the metal tightly, while a collet fits snugly around it. These devices help keep the metal steady, which makes our cuts smooth and accurate. When we use them correctly, we can make precise shapes and sizes easily.

How Do You Select The Appropriate Chuck Type (E.G., Three-Jaw, Four-Jaw, Collet) For Specific Lathe Applications?To choose the right chuck type for a lathe, think about what you’re working on. A three-jaw chuck is great for round pieces, like pipes. A four-jaw chuck is better for more tricky shapes because you can adjust each jaw separately. A collet holds small or odd-shaped tools tightly. Pick the one that fits your project best!

What Are The Advantages And Disadvantages Of Using A Tailstock Versus A Steady Rest For Supporting Long Or Slender Workpieces During Turning?Using a tailstock is great because it helps hold the workpiece steady while you cut it. It gives extra support from the end. However, it can get in the way sometimes. A steady rest offers more support along the length of the piece. But, it’s harder to set up. So, choose based on what you need!

How Can The Use Of Dedicated Fixtures Improve Efficiency And Accuracy When Machining Complex Parts On A Metal Lathe?Using dedicated fixtures helps us keep parts in the right place when we work on them. This means we can make cuts more accurately. When parts fit perfectly, we save time and don’t have to fix mistakes. Overall, we work faster and get better results. This makes our jobs easier and the parts we make more precise.

What Safety Considerations Should Operators Keep In Mind When Securing Workpieces In A Lathe To Prevent Accidents Or Injuries?When you secure a workpiece on a lathe, always make sure it’s tight. Check that the piece won’t move while the lathe is spinning. Keep your hands and clothes away from the moving parts. Wear safety goggles to protect your eyes. Lastly, always follow safety rules to avoid accidents.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Certainly! Here Are Five Related Questions On The Topic Of Lathe Workholding And Metal Lathe Parts:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! When using a lathe, workholding means keeping the metal piece steady while we shape it. We can use different tools like chucks or vises to hold our metal. These tools help us get accurate shapes and sizes. Always make sure everything is tight before starting. This keeps our work safe and look great!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Just ask your question, and I’ll be happy to help you out.”}},{“@type”: “Question”,”name”: “What Are The Different Types Of Workholding Devices Used In Metal Lathe Operations, And How Do They Affect Precision Machining?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “In metal lathe operations, we use different workholding devices to hold metal pieces in place. Some common types are chucks and collets. A chuck grabs the metal tightly, while a collet fits snugly around it. These devices help keep the metal steady, which makes our cuts smooth and accurate. When we use them correctly, we can make precise shapes and sizes easily.”}},{“@type”: “Question”,”name”: “How Do You Select The Appropriate Chuck Type (E.G., Three-Jaw, Four-Jaw, Collet) For Specific Lathe Applications?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To choose the right chuck type for a lathe, think about what you’re working on. A three-jaw chuck is great for round pieces, like pipes. A four-jaw chuck is better for more tricky shapes because you can adjust each jaw separately. A collet holds small or odd-shaped tools tightly. Pick the one that fits your project best!”}},{“@type”: “Question”,”name”: “What Are The Advantages And Disadvantages Of Using A Tailstock Versus A Steady Rest For Supporting Long Or Slender Workpieces During Turning?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Using a tailstock is great because it helps hold the workpiece steady while you cut it. It gives extra support from the end. However, it can get in the way sometimes. A steady rest offers more support along the length of the piece. But, it’s harder to set up. So, choose based on what you need!”}},{“@type”: “Question”,”name”: “How Can The Use Of Dedicated Fixtures Improve Efficiency And Accuracy When Machining Complex Parts On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Using dedicated fixtures helps us keep parts in the right place when we work on them. This means we can make cuts more accurately. When parts fit perfectly, we save time and don’t have to fix mistakes. Overall, we work faster and get better results. This makes our jobs easier and the parts we make more precise.”}},{“@type”: “Question”,”name”: “What Safety Considerations Should Operators Keep In Mind When Securing Workpieces In A Lathe To Prevent Accidents Or Injuries?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When you secure a workpiece on a lathe, always make sure it’s tight. Check that the piece won’t move while the lathe is spinning. Keep your hands and clothes away from the moving parts. Wear safety goggles to protect your eyes. Lastly, always follow safety rules to avoid accidents.”}}]}