Have you ever wondered how metal parts are shaped with perfect accuracy? One of the secrets lies in lathe workholding. It sounds complicated, but it’s quite simple once you get to know it.

When using a metal lathe, a quick change tool post can make a big difference. Imagine you need to switch tools fast while working on a project. With this tool post, you can do just that! It saves time and keeps your work smooth.

Here’s a fun fact: Many metalworkers believe that mastering workholding can make you a better craftsman. Just think of it like this — using the right tools makes all the difference. Why struggle when you can work smarter?

This article will dive into the world of lathe workholding. You’ll learn why the quick change tool post is a must-have for any metal lathe user. Get ready to sharpen your skills and boost your creativity with each turn of the lathe!

Lathe Workholding: Metal Lathe Quick Change Tool Post Techniques

Lathe Workholding: Metal Lathe Quick Change Tool Post

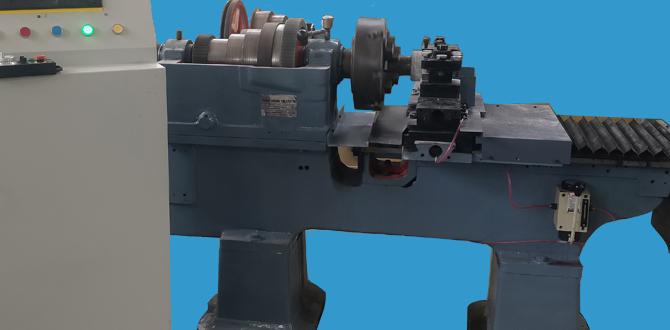

Lathe workholding is key for accurate machining. The quick change tool post is a game changer. Imagine switching tools in seconds instead of minutes! This feature boosts productivity and saves time. Users enjoy improved precision since tools stay aligned better. Did you know that a well-fitted tool post can reduce wear on tools? With a quick change tool post, every project can feel effortless. It’s a must-have for any serious machinist. Wouldn’t you want to make your work easier?Types of Workholding Devices

Description of common workholding devices (chucks, collets, fixtures). Comparison of advantages and disadvantages of each type.Workholding devices are essential for lathe operations. Let’s dive into three common types: chucks, collets, and fixtures. Chucks grip the workpiece firmly and are easy to use. They can handle various sizes. However, they sometimes wobble, which is not ideal. Collets offer a snug fit, making them perfect for small and precise tasks. Yet, they may not accommodate larger items. Fixtures are custom-made holders for specific jobs. They’re strong, but building one can take time.

| Device | Advantages | Disadvantages |

|---|---|---|

| Chucks | Easy to use, versatile | Can wobble, less precision |

| Collets | Snug fit, high precision | Limited size range |

| Fixtures | Very strong, tailored fit | Time-consuming to create |

Choosing the right device is like picking the right pizza topping. It can make all the difference in getting the best result! So, which one do you fancy?

Quick Change Tool Posts: An Essential Component

Explanation of what a quick change tool post is. Benefits of using a quick change tool post in lathe operations.A quick change tool post is a special device on a metal lathe. It allows you to switch tools quickly and easily. This saves time and keeps projects moving smoothly. Using a quick change tool post has many benefits:

- Faster Tool Changes: Change tools in seconds.

- Increased Efficiency: Get more done in less time.

- Better Accuracy: Keep tools aligned correctly.

- Improved Safety: Reduce the chance of errors.

Overall, this tool makes lathe work easier and faster!

What are the benefits of a quick change tool post?

The main benefits include faster tool changes that save time, better accuracy in cuts, and increased safety by reducing mistakes. All these features make it a key part of lathe work.

Installation and Setup of Quick Change Tool Post

Stepbystep guide on installing a quick change tool post. Tips for ensuring proper alignment and secure mounting.Ready to make tool changing a breeze? Start by gathering all your tools. First, remove the old tool post by unscrewing it. Next, place your new quick change tool post where the old one was, making sure it’s aligned properly. Tighten the screws gently, but not too tight! You don’t want to send things flying. Not an acrobat, right? Check your alignment by placing a tool and ensuring it sits snugly. For those who love tables, here’s a quick checklist:

| Steps | Tips |

|---|---|

| 1. Gather tools | Use a soft cloth to avoid scratches. |

| 2. Remove old post | Don’t drop any screws! Use a magnet if needed. |

| 3. Place new post | Make sure it’s aligned like a squad ready for a game! |

| 4. Tighten screws | Don’t play Hulk here—tighten gently. |

| 5. Check alignment | Sit at eye level to inspect. |

Following these steps ensures your quick change tool post is set up right. Happy turning!

Using a Quick Change Tool Post Efficiently

Best practices for switching tools quickly and safely. Common mistakes to avoid when using a quick change tool post.Switching tools on a lathe can feel like playing a game of musical chairs. But, when you use a quick change tool post well, it’s easy-peasy! Here are some best practices: always check that your tools are tight before starting. That way, they won’t go flying off like a rogue frisbee.

Watch out for common mistakes, too. One biggie? Forgetting to align tools properly can ruin your work. Remember: safety first! Follow these tips, and you can be a lathe superhero in no time!

| Best Practices | Common Mistakes |

|---|---|

| Check tool tightness | Misalignment of tools |

| Keep the workspace clean | Skipping tool inspections |

| Use right speed settings | Forgetting to wear safety gear |

Maintenance of Quick Change Tool Posts

Recommended maintenance routines for longevity and performance. Troubleshooting issues with quick change tool posts.Taking good care of quick change tool posts keeps them working well. Regular maintenance helps them last longer. Here are a few tips:

- Clean the tool post regularly to remove dirt.

- Check for wear and tear. Replace damaged parts.

- Lubricate moving parts to prevent rust.

- Ensure tight connections for safety.

If you face problems, try these fixes:

- Check for loose screws or bolts.

- Look for blockages in the tool path.

- Test the alignment of the tool post.

Following these steps can keep your tools in top shape!

How often should I maintain my quick change tool post?

It’s best to maintain your tool post every few weeks or after heavy use. This ensures it works efficiently and lasts longer.

Comparative Analysis: Quick Change Tool Post vs. Traditional Tool Holders

Detailed comparison of quick change tool posts to traditional hold methods. Situations where quick change tool posts may not be ideal.Quick change tool posts are like speedy superheroes for your lathe! They let you swap tools faster than you can say “machine shop.” In contrast, traditional holders take their sweet time, making you feel like you’re waiting for a snail to cross the road. However, quick change posts might not be your best buddy for every job. They can sometimes be tricky for very heavy tools or precise setups. But hey, they shine in fast-paced work where time is money!

| Feature | Quick Change Tool Post | Traditional Tool Holder |

|---|---|---|

| Change Speed | Fast! | Slower |

| Precision | Good | Very Good |

| Tool Weight Limit | Light to Medium | Heavy Duty |

Real-World Applications and Case Studies

Examples of industries and scenarios where quick change tool posts excel. Testimonials and feedback from professionals using these tools.Quick change tool posts are heroes in many industries, from auto repair shops to aerospace manufacturing. These nifty tools save time when switching between tasks. For instance, in a busy fabrication shop, workers can change tools in seconds, boosting productivity. A machinist once exclaimed, “I can’t believe I survived without this!” Feedback like this proves how vital they are. Below is a table showing where quick change tool posts shine:

| Industry | Application |

|---|---|

| Automotive | Precision part making |

| Aerospace | Lightweight components |

| Medical | Custom instrument production |

| Construction | Machine tool repairs |

With quick change tool posts, professionals love feeling like superheroes in their workspaces, wielding tools faster than a speeding bullet!

Future Trends in Lathe Workholding Technologies

Emerging technologies in lathe workholding. Predictions on the evolution of quick change tool posts in the industry.Exciting changes are coming to lathe workholding! New technologies are popping up every day. Smart sensors and automation will soon help tool posts change faster than you can say “lathe.” These nifty gadgets will make work easier and quicker.

| Emerging Technology | Impact |

|---|---|

| Smart Sensors | Help keep track of tool condition |

| Automation | Speed up the tool-changing process |

Experts believe quick change tool posts will evolve to be super user-friendly. Imagine a world where swapping tools is as easy as flipping a pancake! This will boost efficiency on the shop floor. Don’t blink—you don’t want to miss these thrilling trends!

Conclusion

In summary, a quick change tool post makes lathe workholding easier and faster. It allows you to swap tools without delays. You save time and improve your projects. By using this tool, you can focus on creativity and precision. To learn more, explore tutorials online or try it out in your next metalworking project. Happy turning!FAQs

Here Are Five Related Questions On The Topic Of Lathe Workholding, Specifically Focusing On Quick Change Tool Posts For Metal Lathes:Quick change tool posts help you switch tools on a metal lathe quickly. This saves time when you’re working on different tasks. You can easily change tools without using extra tools or making a mess. They make your job easier and more efficient. Using a quick change tool post means you can get your work done faster!

Sure! Please let me know what question you would like me to answer.

What Are The Advantages Of Using A Quick Change Tool Post Over A Standard Tool Post In Metal Lathe Operations?Using a quick change tool post is easier and faster than a standard tool post. You can switch tools in just a few seconds. This saves time and makes your work smoother. You won’t have to waste time fiddling with screws or parts. Overall, it helps you finish your projects more quickly!

How Do You Properly Set Up And Align A Quick Change Tool Post On A Metal Lathe?To set up a quick change tool post on a metal lathe, first, clean the area where it will sit. Next, place the tool post on the lathe’s cross slide and tighten it securely. Then, use a piece of scrap metal to check if the tool is level and straight. Adjust the tool post until it cuts smoothly along the metal. Finally, double-check everything to make sure it’s still tight and aligned.

What Types Of Tool Holders Are Compatible With Quick Change Tool Posts, And How Do They Differ?Quick change tool posts work with special tool holders, like lathe tool holders and turning tool holders. These tool holders fit into the quick change system easily. They are different because some hold tools like drills, while others hold cutting tools. You can swap them quickly without needing extra tools. This saves time when working on projects!

How Can You Troubleshoot Common Issues That May Arise When Using A Quick Change Tool Post On A Metal Lathe?To fix common problems with a quick change tool post on a metal lathe, you can start by checking if the tool is tight. If the tool wiggles, it may need to be clamped down better. Next, make sure the tool is set at the right height. If it cuts unevenly, adjust the height until it looks good. Lastly, if the tool post doesn’t move, clean any dirt or chips around it so it can slide easily.

What Maintenance Practices Should Be Followed To Ensure The Longevity And Accuracy Of A Quick Change Tool Post?To keep a quick change tool post in good shape, you should regularly clean it. Make sure to remove any dust and chips. Check for any rust or damage and fix it right away. Always use the right tools and parts when you change things. Finally, after using it, oil the moving parts to keep everything working smoothly.