Have you ever wondered how metal items are made with such precision? The answer often lies in lathe workholding. This process allows craftsmen to secure a piece firmly in place on a metal lathe. A quill plays a crucial role here. It helps control the tool movement.

Imagine a craftsman creating a beautiful metal vase. The vase starts as a simple round piece of metal. The lathe spins it, allowing the craftsman to carve and shape it. Without proper workholding, that metal would wobble and ruin the design.

Did you know that the right setup can change everything? A stable quill can mean the difference between a perfect cut and a messy fail. This makes learning about lathe workholding essential for anyone interested in metalwork.

So, what makes a great workholding setup? Let’s dive deeper into how the quill and other tools can help you achieve stunning results.

Effective Lathe Workholding: Mastering Metal Lathe Quill Techniques

Discovering Lathe Workholding with Metal Lathe Quill

Lathe workholding is key for precision in metalworking. The metal lathe quill plays an important role here. It secures the workpiece, allowing smooth and accurate cuts. Imagine trying to cut a piece of wood without holding it still. It wouldn’t turn out well, right? Quills can be adjusted for different tasks, making them handy tools. Knowing how to use a quill can enhance your skills and make your projects easier. Whether you’re a pro or just starting, understanding quill usage is vital. It’s a game-changer!Understanding the Metal Lathe Quill

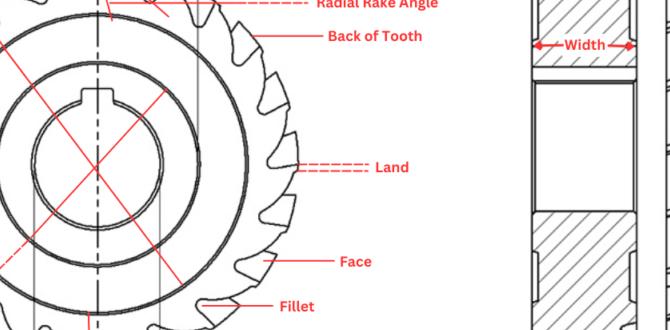

Definition and function of the quill in metal lathes. Different types of quills and their applications.The quill of a metal lathe is like the superhero sidekick. It supports the spindle, holding the cutting tools in place. Depending on the job, there are different types of quills. Some are designed for heavy-duty work, while others are perfect for fine details. The right quill can make or break your project, just like a good sidekick can help you save the day!

| Type of Quill | Application |

|---|---|

| Fixed Quill | Good for standard cuts |

| Adjustable Quill | Best for varied precision tasks |

| Live Quill | Ideal for rotary work or drilling |

Choosing the right quill is important. It can help you work smarter, not harder!

Importance of Proper Workholding

Significance of workholding in achieving precision. Common issues caused by improper workholding.Using the right workholding is key for precision in lathe work. Good workholding grips the material tightly, so it doesn’t move. When materials shift, it can cause a poor cut. This can lead to mistakes and wasted time.

- Common issues with improper workholding include:

- Poor surface finish

- Inaccurate measurements

- Increased tool wear

Keeping the work secure makes for better results. Always check your setup, so you avoid frustrating problems. Remember, “A good grip leads to a perfect cut!”

Why is workholding important?

Proper workholding ensures accuracy and quality in metal lathe projects. It helps create smooth and precise cuts, which are important for any lathe work.

Common Issues with Improper Workholding:

- Poor surface finish

- Inaccurate measurements

- Increased tool wear

Setting Up the Quill for Optimal Performance

Stepbystep guide to calibrating the quill. Tips for ensuring stability and alignment.To get your quill ready for action, start by calibrating it step by step. First, check the quill’s height with a trusty ruler. Adjust until it’s level—like your best friend’s smile! Next, ensure it’s properly tightened; we don’t want any wobbling like a jelly on a rollercoaster. Stability is key!

| Step | Action |

|---|---|

| 1 | Measure quill height |

| 2 | Adjust for level |

| 3 | Tighten securely |

Finally, double-check alignment. You want it straighter than your teacher when grading at midterms! Following these tips will make your lathe work smoother than a peanut butter sandwich. Remember, a well-prepared quill means better results!

Techniques for Effective Workholding

Best practices for securing workpieces in the quill. Techniques for minimizing vibrations and improving accuracy.Effective workholding is key for great results. First, always secure your workpiece tightly in the quill. Use proper clamps to hold it steady. This reduces wobbles. Next, consider the following tips:

- Check your setup before starting.

- Minimize vibrations by tightening all parts.

- Use dampening materials to absorb shocks.

- Ensure a balanced setup to improve accuracy.

These practices help make your lathe work safer and more precise. Remember, a good setup leads to better projects!

How can I secure my workpiece in the quill?

You can secure your workpiece in the quill by using clamps and vices. Tighten them to make sure the piece stays still while you work.

Common Challenges in Lathe Workholding

Identification of typical problems faced by machinists. Solutions and troubleshooting tips for effective workholding.Machinists often face challenges while clamping workpieces in a lathe. One common issue is poor alignment. This can lead to uneven cuts and wasted material. Another problem is vibration, which can make your part dance like it’s at a disco! To tackle these problems, ensure your workpiece is centered and use proper clamps. Regularly check your setup to avoid surprise wobbles.

| Challenge | Solution |

|---|---|

| Poor alignment | Center your workpiece. |

| Excessive vibration | Use sturdy clamps. |

Remember, a little attention can save a lot of headaches. So, let’s keep those quills steady!

Case Studies: Successful Lathe Workholding Applications

Analysis of realworld examples demonstrating effective quill use. Lessons learned from industry leaders in metalworking.In metalworking, using quills effectively can make a big difference. Many successful companies share their stories. Here are some lessons learned:

- Better hold means better quality. A firm grip prevents mistakes.

- Using the right tools saves time. Choosing the best quill can speed things up.

- Training workers is important. Skilled hands create better products.

- Regular maintenance keeps machines running smooth. This prevents costly breakdowns.

Many leaders in this field say, “A smart workspace is a safe workspace.” They stress the value of good planning and safety. Each case teaches us something new about using a lathe effectively.

What are some best practices for lathe workholding?

Best practices include choosing the right quill, training staff, and ensuring regular maintenance of tools. These steps create a safer workspace and improve productivity.

Safety Tips for Lathe Workholding

Essential safety protocols to follow when using metal lathe quills. Common safety hazards and how to avoid them.Using a metal lathe quill can be fun, but safety is key. Always wear safety glasses to protect your eyes. Keep hands away from moving parts. Ensure all tools are sharp and secure. Follow these tips:

- Clear the area of clutter.

- Always use the right tool for the job.

- Check for loose clothing before starting.

- Turn off the machine when not in use.

These steps help prevent injury and accidents. Stay alert and keep your workspace safe!

What are some common safety hazards of lathe workholding?

Common hazards include flying chips, machine contact, and loose clothing. Always stay focused and follow safety rules.

Conclusion

In summary, understanding lathe workholding on a metal lathe quill is crucial for precision. You secure your material properly for better results. This helps you avoid mistakes and makes your projects easier. We encourage you to explore more about lathe techniques and practice them. You’ll improve your skills and create amazing items! Happy turning!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Workholding, Specifically Focusing On The Quill Of A Metal Lathe:The quill on a metal lathe helps hold and move tools to make shapes. It can slide in and out to be very useful. You adjust the quill to get the right depth of cut. This makes sure the tool does its job well. Always be careful when working with the lathe to stay safe!

Sure! Just let me know what question you want me to answer, and I’ll be happy to help!

What Are The Different Types Of Workholding Devices Utilized In Conjunction With The Quill Of A Metal Lathe?In a metal lathe, we use different tools to hold the metal piece while we work on it. A common tool is a chuck, which grips the metal tightly from the outside. There are also centers, which hold the metal by fitting into its ends. We can use clamping bars too, which can squeeze the metal down onto the lathe. Each of these tools helps keep the metal steady while we shape it.

How Does The Quill Of A Metal Lathe Influence The Accuracy And Precision Of Machining Operations?The quill of a metal lathe holds the cutting tool. When the quill is steady and well-aligned, it helps make smoother cuts. This leads to better and more precise shapes on the metal. If the quill is loose or off, it can cause mistakes. So, a good quill makes your work more accurate!

What Are The Advantages And Disadvantages Of Using A Quill Chuck Versus A Tailstock In Lathe Workholding?A quill chuck is great because it holds things tightly and is easy to adjust. You can change the position quickly. But, it can be more expensive than a tailstock. The tailstock is cheaper and very reliable, but it might take longer to set up. We can choose either based on what we need to do!

How Can Proper Alignment Of The Quill Enhance The Overall Performance Of A Metal Lathe During Operations?When the quill is properly aligned on a metal lathe, it helps the machine work better. This means you make smoother and more accurate cuts. If the quill is off, you might end up with mistakes or rough edges. By keeping everything straight, we can make strong and neat pieces of metal. Proper alignment makes our work easier and more fun!

What Safety Considerations Should Be Taken Into Account When Using The Quill For Workholding On A Metal Lathe?When you use the quill to hold your work on a metal lathe, keep safety in mind. Always wear safety goggles to protect your eyes. Make sure your hair and clothes are tied back and not loose. Check that the quill is tight before starting. Stay alert and keep your hands away from moving parts.