Have you ever wondered how metal is shaped into beautiful objects? A lathe workshop is where all the magic happens. Here, skilled builders use a metal lathe to turn raw materials into detailed pieces. But, what makes a workshop truly effective? A well-thought-out lathe workshop setup plays a big role in this.

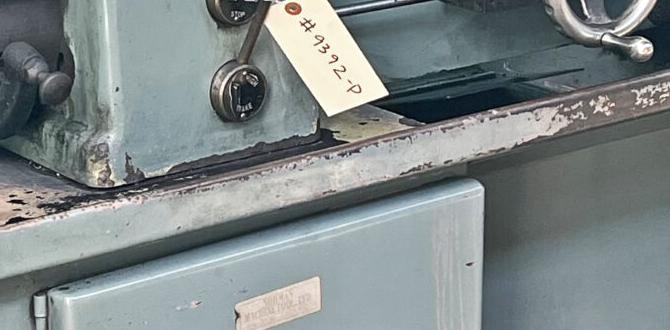

Imagine walking into a workshop filled with the hum of machines and the smell of metal. You see a metal lathe sitting proudly, ready for action. But do you know how to keep it in top shape? Metal lathe maintenance is key to making sure your workshop runs smoothly.

Interestingly, did you know that many famous inventors started their journeys in places just like this? They learned the importance of a tidy workspace and a well-maintained lathe early on. With the right setup and care, anyone can create amazing projects. Let’s explore how to create the perfect space for your metal lathe and ensure it’s always ready to work!

Comprehensive Guide To Lathe Workshop Setup And Metal Lathe Maintenance

Lathe Workshop Setup and Metal Lathe Maintenance

Setting up a lathe workshop can be exciting! First, you need a sturdy workbench and good lighting. Have you ever wondered how to keep your metal lathe running smoothly? Regular maintenance is key. This includes cleaning, oiling parts, and checking for wear. Did you know that small, simple tasks can save you money in the long run? By caring for your lathe, you can create amazing projects with ease. Keep your tools and workspace organized for the best results!Choosing the Right Location for Your Lathe Workshop

Factors to consider: space, ventilation, and safety. Importance of layout for workflow efficiency.Finding the best spot for your lathe can feel like playing a game of “musical chairs.” First, check your space—make sure it’s big enough for your lathe and you! Ventilation is also key; we want fresh air, not that funky smell from old projects. Safety matters too, so pick a place away from clowning around or where tools can wander off. Think about how you move around. A good layout helps you work faster, like knowing the secret shortcut in a video game. Plan wisely!

| Factor | Tips |

|---|---|

| Space | Make sure there’s enough room to move freely. |

| Ventilation | Open windows or fans help keep the air fresh. |

| Safety | Choose a spot away from hazards to avoid mishaps! |

| Layout | Arrange tools so you can grab what you need quickly. |

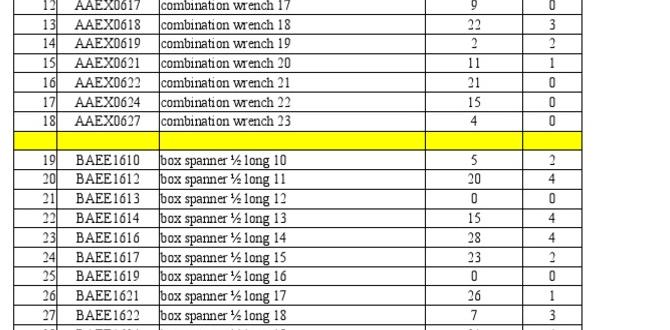

Essential Tools and Equipment for a Metal Lathe Workshop

List of musthave tools for lathe operations. Additional equipment for maintenance and safety.To create a successful metal lathe workshop, having the right tools is crucial. These tools help you work safely and effectively. Here’s a list of must-have tools for lathe operations:

- Metal lathe

- Cutting tools

- Measuring tools

- Chucks

- Tool holders

Besides these, additional equipment is important for maintenance and safety. This includes:

- Safety goggles

- Cleaning brushes

- Lubricants

- Wrenches

- Calipers

What tools do I need for lathe operations?

The essential tools for lathe operations include cutting tools, chucks, and measuring tools. These help you get precise cuts and measurements.

Setting Up Your Metal Lathe: Step-by-Step Process

Key considerations for proper lathe placement and stability. Wiring and power requirements for optimal performance.Choosing the right spot for your metal lathe is crucial. It needs a flat, steady surface. A wobbly table? That’s a recipe for disaster and maybe a flying toolbox! Make sure it’s close to power outlets for easy wiring. Your machine doesn’t like long extension cords. For power, check that your lathe is compatible with the voltage in your workshop. A sudden power surge can ruin your day. Here’s a handy table:

| Consideration | Details |

|---|---|

| Surface | Flat and stable |

| Space | Avoid tight corners; allow movement |

| Power Supply | Correct voltage and nearby outlet |

These tips will help your lathe run smoothly, and keep you in one piece while you spin away!

Workspace Organization and Workflow Optimization

Techniques for organizing tools and materials effectively. Creating a logical workflow to improve productivity.Keeping your workspace tidy is like giving your brain a vacation. Organize tools and materials by using pegboards, bins, and labels. This helps you find things faster and keep clutter at bay. Turn chaos into order! For a smooth workflow, think of your tasks as a dance routine. Move from one step to another without tripping over your own feet. Place tools where you’ll use them, just like a ninja keeps weapons ready!

| Technique | Benefit |

|---|---|

| Pegboards | Easy access to tools |

| Bins | Reduces clutter |

| Labels | Quick find, less stress |

Creating a logical workflow boosts productivity. Move with purpose! Always plan your steps. Since well-organized workshops can improve efficiency by up to 30%, why not give it a shot? It’s like turning your workstation into a well-oiled machine. Keep it clean, keep it fun!

Basic Metal Lathe Maintenance Practices

Routine maintenance tasks to extend the lathe’s lifespan. Importance of cleanliness and lubrication.To keep your metal lathe running smoothly, routine maintenance is essential. A clean lathe helps prevent dust and debris from causing damage. Regularly check and tighten all parts. Lubrication is key too; it keeps moving parts from wearing out.

- Clean the lathe after each use.

- Oil moving parts monthly.

- Inspect belts and gears regularly.

These simple tasks can significantly extend the lathe’s lifespan. Following these practices can save you time and money in the long run.

Why is cleanliness important for my lathe?

Cleanliness prevents rust and wear, helping your lathe run better and longer.

How often should I lubricate my metal lathe?

It’s best to lubricate your lathe monthly, or more often if used heavily.

Advanced Maintenance Techniques for Metal Lathes

Troubleshooting common lathe issues. Calibration and adjustment for precision performance.Metal lathes can have problems, but troubleshooting them can be simple. Check for common issues like strange noises or vibrations. These sounds often mean something may be loose or misaligned. Calibration helps keep your lathe precise. Adjust parts so they fit perfectly, ensuring smooth cuts. Regular checks boost performance and extend your lathe’s life.

What are some common issues with metal lathes?

Common problems include misalignment, vibrations, and excessive noise. These issues can lead to errors in your work.

Tips for Troubleshooting:

- Listen for odd sounds.

- Look for loose parts.

- Check alignment regularly.

Staying on top of these maintenance tasks will ensure amazing results from your metal lathe!

Safety Precautions in the Lathe Workshop

Personal protective equipment (PPE) essentials. Best practices to minimize risks while operating a lathe.Working in a lathe workshop can be exciting, but safety comes first! Always wear personal protective equipment (PPE) like goggles, gloves, and ear protection. It’s like wearing superhero armor, ready to battle flying chips and noise! Stay alert and avoid loose clothing that could get caught in the machine. Before you start, check for any hazards. Ready to make shavings and have fun? Just remember, safety first means you get to keep your fingers and hearing!

| PPE Essentials | Best Practices |

|---|---|

| Goggles | Keep your workspace clean. |

| Gloves | Don’t rush—take your time. |

| Ear Protection | Check tools before you use them. |

Resources for Further Learning and Development

Recommended books, online courses, and forums for lathe enthusiasts. Connecting with local metalworking communities and workshops.Exploring new techniques in metalworking can be tons of fun! For those eager to learn, there are great resources available. Books like “The Metal Lathe” by J. M. Gray offer solid guidance. Online courses on platforms like Udemy and Coursera provide hands-on learning. Don’t forget about forums like The Home Machinist, where you can connect with fellow lathe lovers. Local communities often host workshops, turning metalworking into a group activity. Remember, why work alone when you can have a buddy to help with those tricky cuts?

| Resource Type | Suggestions |

|---|---|

| Books | “The Metal Lathe” by J. M. Gray |

| Online Courses | Udemy, Coursera |

| Forums | The Home Machinist |

| Workshops | Local metalworking community events |

Conclusion

To maintain your lathe workshop, keep your metal lathe clean and lubricated. Regularly check for wear and tear on parts. Organize your workspace for easy access to tools. Follow these tips to ensure smooth operations. You can further enhance your skills by reading more about lathe maintenance techniques or joining a workshop. Start today to become a lathe expert!FAQs

Certainly! Here Are Five Questions Related To Lathe Workshop Setup And Metal Lathe Maintenance:Sure! Here are five questions about setting up a lathe workshop and keeping a metal lathe in good shape: 1. How do you set up a lathe safely? 2. What tools do you need for a lathe? 3. How often should you clean the lathe? 4. What is the best way to check if the lathe works well? 5. How do you fix minor problems with the lathe?

Of course! Please provide me with the question you want answered.

What Are The Essential Tools And Equipment Required For Setting Up A Metal Lathe In A Workshop?To set up a metal lathe in a workshop, you need a few important tools and equipment. First, you need a sturdy workbench to hold the lathe. Next, you should have measuring tools like calipers and a ruler to help you be accurate. You also need cutting tools, like drill bits and blades, to shape the metal. Finally, safety gear like goggles and gloves are important to keep you safe while working.

How Can You Ensure Proper Alignment And Leveling Of A Metal Lathe During Installation?To make sure a metal lathe is level and aligned, first check its feet are on a flat surface. You can use a level tool to see if it’s straight. If it tilts, you can adjust the feet or add shims to balance it. Next, use a ruler to check that the parts of the lathe line up correctly. This way, your lathe will work better!

What Regular Maintenance Practices Should Be Implemented To Prolong The Lifespan Of A Metal Lathe?To help your metal lathe last longer, you should keep it clean. Wipe off dust and metal shavings after each use. Check and change the oil regularly to keep it running smoothly. Tighten any loose parts and look for signs of wear. Lastly, cover it with a cloth when not in use to protect it from dust.

How Can You Identify And Troubleshoot Common Issues That May Arise In The Operation Of A Metal Lathe?To find problems with a metal lathe, you should watch for strange noises or vibrations. Check if the tools are sharp and well-fixed. If your metal piece isn’t shaping right, it may need a better setup. Always clean the lathe after use to keep it working well. If you notice any part that looks broken, ask someone for help.

What Safety Precautions Should Be Taken While Operating And Maintaining A Metal Lathe In A Workshop Environment?When using a metal lathe, always wear safety goggles to protect your eyes. Make sure your hair is tied back and you wear fitted clothing. Keep your hands away from moving parts. Always turn off the machine before changing tools or cleaning. Finally, keep the area around the lathe clean and free from clutter.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Certainly! Here Are Five Questions Related To Lathe Workshop Setup And Metal Lathe Maintenance:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are five questions about setting up a lathe workshop and keeping a metal lathe in good shape: 1. How do you set up a lathe safely? 2. What tools do you need for a lathe? 3. How often should you clean the lathe? 4. What is the best way to check if the lathe works well? 5. How do you fix minor problems with the lathe?”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Of course! Please provide me with the question you want answered.”}},{“@type”: “Question”,”name”: “What Are The Essential Tools And Equipment Required For Setting Up A Metal Lathe In A Workshop?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To set up a metal lathe in a workshop, you need a few important tools and equipment. First, you need a sturdy workbench to hold the lathe. Next, you should have measuring tools like calipers and a ruler to help you be accurate. You also need cutting tools, like drill bits and blades, to shape the metal. Finally, safety gear like goggles and gloves are important to keep you safe while working.”}},{“@type”: “Question”,”name”: “How Can You Ensure Proper Alignment And Leveling Of A Metal Lathe During Installation?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To make sure a metal lathe is level and aligned, first check its feet are on a flat surface. You can use a level tool to see if it’s straight. If it tilts, you can adjust the feet or add shims to balance it. Next, use a ruler to check that the parts of the lathe line up correctly. This way, your lathe will work better!”}},{“@type”: “Question”,”name”: “What Regular Maintenance Practices Should Be Implemented To Prolong The Lifespan Of A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To help your metal lathe last longer, you should keep it clean. Wipe off dust and metal shavings after each use. Check and change the oil regularly to keep it running smoothly. Tighten any loose parts and look for signs of wear. Lastly, cover it with a cloth when not in use to protect it from dust.”}},{“@type”: “Question”,”name”: “How Can You Identify And Troubleshoot Common Issues That May Arise In The Operation Of A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To find problems with a metal lathe, you should watch for strange noises or vibrations. Check if the tools are sharp and well-fixed. If your metal piece isn’t shaping right, it may need a better setup. Always clean the lathe after use to keep it working well. If you notice any part that looks broken, ask someone for help.”}},{“@type”: “Question”,”name”: “What Safety Precautions Should Be Taken While Operating And Maintaining A Metal Lathe In A Workshop Environment?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using a metal lathe, always wear safety goggles to protect your eyes. Make sure your hair is tied back and you wear fitted clothing. Keep your hands away from moving parts. Always turn off the machine before changing tools or cleaning. Finally, keep the area around the lathe clean and free from clutter.”}}]}