Have you ever wondered how metal lathes work? These machines can turn raw metal into amazing shapes. But, have you thought about what it takes to set up a lathe workshop? A good setup is key to making the most of your metal lathe.

Imagine you’re in a workshop filled with tools. You see different metal pieces waiting to be shaped. It excites you, but safety must come first. Setting up your lathe workshop safely can keep you and others out of harm’s way.

Safety is not just a rule; it is a way to enjoy your workshop. For example, did you know that many accidents happen because of a simple mistake? A single misunderstanding about safety can lead to serious injuries. That’s why it’s important to know metal lathe safety tips before you start your project.

This article will guide you through how to set up your lathe workshop safely. From choosing the right space to understanding essential safety gear, you will learn it all. Let’s dive into the world of metal lathes and discover how safety can transform your workshop experience!

Lathe Workshop Setup: Metal Lathe Safety Essentials

Lathe Workshop Setup: Metal Lathe Safety

Setting up a metal lathe workshop safely is crucial for preventing accidents. Always wear safety goggles and keep hands away from moving parts. Did you know that over 50% of lathe accidents happen due to carelessness? Secure your workpiece well to avoid slips. Make sure your workspace is clutter-free. Also, regularly maintain your lathe to ensure it runs smoothly. Remember, safety isn’t just a guideline; it’s essential for every successful project.Understanding Lathe Basics

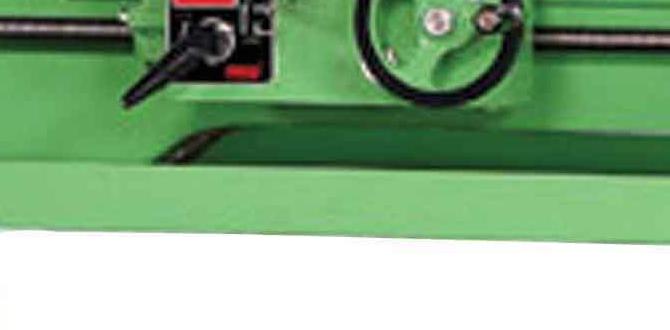

Definition and purpose of a lathe. Various types of metal lathes available on the market.A lathe is a tool used to shape materials like metal or wood. It spins the material, allowing the user to cut it into different shapes. Lathes are essential in many workshops for creating parts and tools. There are different types of metal lathes. Each is designed for specific tasks, making them useful for various projects. Here are some common types:

- Engine Lathe: Great for general purpose work.

- Toolroom Lathe: Used for precise and detailed work.

- CNC Lathe: Computer-controlled for automated tasks.

- Bench Lathe: Small and ideal for hobbyists.

Understanding the lathe helps in making safe and effective designs.

What is the main purpose of a lathe?

The main purpose of a lathe is to shape materials by removing material in a controlled way. It creates various parts, which helps in machines and projects.

Essential Tools and Equipment for a Lathe Workshop

List of necessary tools for lathe operation. Importance of quality and maintenance of tools.Setting up a lathe workshop means having the right tools. Essential tools include:

- Metal lathe

- Chisels and cutting tools

- Measuring tools like calipers

- Workholding devices

- Safety gear (gloves and goggles)

Quality is crucial. Good tools last longer and work better. Maintain them by cleaning and checking them often. This keeps your workshop safe and running smoothly.

What tools are needed for lathe operation?

The main tools you need are metal lathes, chisels, measuring tools, and safety gear. Having these tools helps you work safely and effectively.

Choosing the Right Location for Your Lathe Workshop

Key considerations for space selection. Environmental factors that affect lathe operation.Finding the best spot for your lathe workshop is super important. First, look for enough space to move around without bumping into things. You don’t want to trip over a stray toolbox! Good ventilation is key; it keeps the air fresh and helps with dust. Also, consider the lighting since shadows can be sneaky. If you can avoid windows with direct sunlight, do it! Too much light can blind you during crucial cuts. Here’s a quick table to consider:

| Factor | Importance |

|---|---|

| Space | Allows safe movement |

| Ventilation | Reduces dust and fumes |

| Lighting | Improves visibility |

By picking the right location, you’re already one step closer to a safe and fun workshop!

Setting Up Your Lathe Workstation

Ideal layout for maximizing efficiency. Ergonomic considerations for operator comfort.To create an effective lathe workstation, start with the right layout. Place your lathe in a spot where you have enough space to work and move around. This will help keep things efficient and safe. Make sure tools are within reach. Ergonomic factors are key too! Use tools that feel comfortable in your hands and adjust your chair for better posture. This keeps you relaxed and focused while you work.

- Keep tools organized nearby.

- Ensure good lighting in the area.

- Adjust the height of your lathe to suit your preference.

What is the best layout for a lathe workstation?

The best layout keeps tools close and the workspace clear. This setup saves time and reduces frustration.

Proper Use of Metal Lathes

Stepbystep guide to operating a metal lathe. Importance of following operational procedures.Using a metal lathe can be fun and rewarding. First, always wear safety gear like goggles. Next, follow the steps to operate your lathe safely. Start by checking the machine for any loose parts. Then, secure your material firmly. Don’t forget to adjust the speed based on the type of metal. Always keep your hands away from the cutting area. Remember, safety isn’t just a suggestion; it’s a must! After all, nobody wants to lose a finger while trying to make something cool!

| Step | Action |

|---|---|

| 1 | Wear safety goggles |

| 2 | Check machine parts |

| 3 | Secure the material |

| 4 | Adjust speed |

| 5 | Keep hands clear |

Routine Maintenance and Inspection

Key maintenance tasks to ensure lathe longevity. How to conduct a safety inspection before use.Keeping your lathe in good shape is key for long life and safety. Regular checks can prevent big problems. Here are some important tasks:

- Clean the machine after each use.

- Check and change the oil regularly.

- Inspect belts and parts for wear.

- Keep the workspace tidy.

Before using your lathe, always ensure a safety check:

- Look for loose parts.

- Test safety guards.

- Check power cords and switches.

Doing these things makes your lathe run better and keeps you safe!

Why is lathe maintenance important?

Lathe maintenance is crucial because it helps avoid breakdowns and keeps your projects smooth and safe.

Advanced Safety Tips for Experienced Operators

Best practices for complex operations. Handling unforeseen situations and emergencies.Making your workshop safe is like having a superhero cape—essential for facing challenges! Experienced operators should follow the best practices while working on complex operations. Always wear goggles; we want your eyes safe, not looking like a raccoon! If something goes wrong, stay calm. Most accidents happen when people panic. Have a plan ready for unforeseen situations. Here’s a quick table to help you out:

| Situation | Action |

|---|---|

| Machine stops suddenly | Turn off the power and assess the issue. |

| Tool slips or jams | Stop immediately and safely release the tool. |

| Noise changes | Investigate promptly; strange sounds can mean trouble! |

Remember, safety first! You can never be too careful in a lathe workshop, especially when you’re the master of the machine. Stay sharp, and don’t let surprises catch you off guard!

Resources for Further Learning

Recommended books and manuals on lathe operation. Online courses and workshops for continuous improvement.If you’re eager to master lathe work, several resources can guide you. Start with some recommended books on lathe operations. They spill the secrets to smooth cuts and safe practices. Online courses are a fun way to keep learning, like a video game that never ends! Want to join a workshop? You’ll meet fellow metal-shapers and possibly swap funny horror stories about their mistakes. Here’s a handy table:

| Resource Type | Title | Link |

|---|---|---|

| Book | Machining Fundamentals | Link |

| Online Course | Lathe Basics in 30 Days | Link |

| Workshop | Intro to Metalworking | Link |

These resources will surely help you become a lathe superstar, minus the cape. Happy turning!

Conclusion

In summary, a lathe workshop setup requires careful planning and safety measures. Always wear protective gear, keep tools organized, and maintain a clean workspace. Remember to read the lathe’s manual for specific instructions. By following these steps, you can work safely and effectively. For more tips, consider reading about tool maintenance or workshop organization. Stay safe and enjoy your projects!FAQs

What Are The Essential Safety Measures To Implement Before Operating A Metal Lathe In A Workshop Setting?Before using a metal lathe, you should always wear safety glasses to protect your eyes. Tie back long hair and remove loose clothing to avoid getting caught in the machine. Check that the machine is clean and all parts are working properly. Keep your hands away from moving parts, and make sure others are at a safe distance. Finally, know how to turn off the lathe quickly in case of an emergency.

How Should Personal Protective Equipment (Ppe) Be Selected And Utilized When Working With A Lathe?When using a lathe, you should wear the right personal protective equipment (PPE) to stay safe. First, wear safety goggles to protect your eyes from flying chips. Next, put on gloves to keep your hands safe from cuts. Don’t forget to wear a dust mask if there’s a lot of dust. Always check your PPE before you start working to ensure it fits well and is clean.

What Steps Should Be Taken To Ensure Proper Machine Maintenance And Inspection In Order To Prevent Accidents During Lathe Operations?To keep lathes safe, we should follow some simple steps. First, we must check the lathe for any damage before using it. Next, we clean it regularly to remove dust and chips. We also need to make sure all parts are tight and work well. Finally, we should read the user manual for more safety tips.

How Can The Workspace Layout Impact Safety While Using A Metal Lathe, And What Considerations Should Be Made?The way we arrange our workspace can help keep us safe when using a metal lathe. For example, we should keep tools and materials within easy reach, so we don’t have to stretch or lean too far. It’s also important to have enough space around the lathe so we don’t bump into things. Finally, good lighting helps us see better, which reduces mistakes and accidents.

What Emergency Procedures Should Be Established In A Lathe Workshop To Respond Effectively To Accidents Or Malfunctions?In a lathe workshop, we should have clear emergency procedures. First, know where the first aid kit is and how to use it. Next, learn the emergency stop button’s location and use it for quick stops. We should also have a plan to call for help if someone is hurt. Lastly, practice these steps together so everyone knows what to do in an emergency.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Essential Safety Measures To Implement Before Operating A Metal Lathe In A Workshop Setting? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Before using a metal lathe, you should always wear safety glasses to protect your eyes. Tie back long hair and remove loose clothing to avoid getting caught in the machine. Check that the machine is clean and all parts are working properly. Keep your hands away from moving parts, and make sure others are at a safe distance. Finally, know how to turn off the lathe quickly in case of an emergency.”}},{“@type”: “Question”,”name”: “How Should Personal Protective Equipment (Ppe) Be Selected And Utilized When Working With A Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using a lathe, you should wear the right personal protective equipment (PPE) to stay safe. First, wear safety goggles to protect your eyes from flying chips. Next, put on gloves to keep your hands safe from cuts. Don’t forget to wear a dust mask if there’s a lot of dust. Always check your PPE before you start working to ensure it fits well and is clean.”}},{“@type”: “Question”,”name”: “What Steps Should Be Taken To Ensure Proper Machine Maintenance And Inspection In Order To Prevent Accidents During Lathe Operations? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep lathes safe, we should follow some simple steps. First, we must check the lathe for any damage before using it. Next, we clean it regularly to remove dust and chips. We also need to make sure all parts are tight and work well. Finally, we should read the user manual for more safety tips.”}},{“@type”: “Question”,”name”: “How Can The Workspace Layout Impact Safety While Using A Metal Lathe, And What Considerations Should Be Made? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The way we arrange our workspace can help keep us safe when using a metal lathe. For example, we should keep tools and materials within easy reach, so we don’t have to stretch or lean too far. It’s also important to have enough space around the lathe so we don’t bump into things. Finally, good lighting helps us see better, which reduces mistakes and accidents.”}},{“@type”: “Question”,”name”: “What Emergency Procedures Should Be Established In A Lathe Workshop To Respond Effectively To Accidents Or Malfunctions? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “In a lathe workshop, we should have clear emergency procedures. First, know where the first aid kit is and how to use it. Next, learn the emergency stop button’s location and use it for quick stops. We should also have a plan to call for help if someone is hurt. Lastly, practice these steps together so everyone knows what to do in an emergency.”}}]}