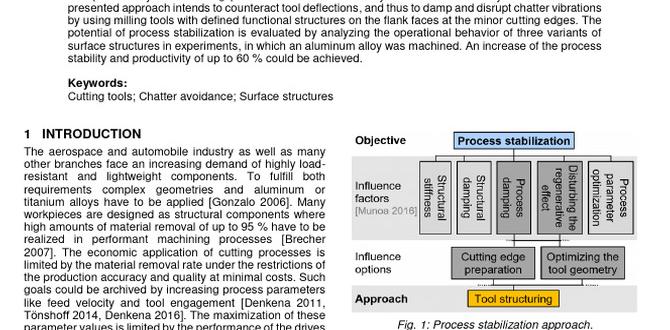

Have you ever stared at a metal lathe and wondered how to use it effectively? If so, you’re not alone. A metal lathe is a fascinating machine that can create amazing parts and shapes. However, understanding how to maintain it is essential for those perfect cuts.

One important feature on a lathe is the threading dial. This little dial helps you make precise threads. But, without proper maintenance, it can become inaccurate. Imagine trying to create a thread and finding out it won’t line up right! What a hassle!

In this article, we’ll explore a maintenance guide for the metal lathe threading dial. You’ll learn tips to keep your lathe in top shape. Plus, you’ll discover why regular checks can save you time and make your projects more fun.

So, ready to dive into the world of metal lathes? Let’s turn that dial! Your lathe is waiting for some expert care.

Comprehensive Maintenance Guide For Metal Lathe Threading Dial

Maintenance Guide for Metal Lathe Threading Dial

Keeping your metal lathe threading dial in top shape is key for smooth operation. Regular checks can prevent costly repairs. Did you know that a simple cleaning can extend the life of your tools? Often, dirt and debris cause the dial to jam. Lubricating moving parts also ensures accuracy when cutting threads. Understanding these basic maintenance steps helps you work safely and efficiently. With a little care, you can keep your lathe running like new!Understanding the Threading Dial

Explanation of the threading dial’s purpose in metal lathes. Different types of threading dials and their features.The threading dial is a key part of metal lathes. It helps you cut threads accurately. By showing you the position of the tool, it makes threading easy and precise.

There are different types of threading dials:

- Star Dial: This type has a star-shaped design. It allows for quick changes and can function well at high speeds.

- Rotary Dial: This one rotates as the lathe turns. It offers consistent readings for better control.

Using the correct threading dial makes your work simpler and helps create better threads.

What is the purpose of a threading dial?

The threading dial helps guide your tool for accurate threading. With it, you can avoid mistakes and make nice threads every time. It is essential for any lathe operator wanting great results!

Importance of Regular Maintenance

Impact of maintenance on threading accuracy and performance. Benefits of a wellmaintained threading dial.Maintaining your threading dial is key to great results. Regular care boosts threading accuracy and keeps your lathe performing well. Good maintenance leads to smooth operation, helping you make perfect threads every time. A well-kept threading dial offers these benefits:

- Increased precision in your work

- Longer tool life

- Reduced risk of accidents

With proper upkeep, you can enjoy stress-free project days. Think of your lathe like a favorite toy; it works best when cared for!

What happens if you don’t maintain the threading dial?

If you don’t maintain the threading dial, it may lose accuracy, causing errors in your work.

Essential Maintenance Tools and Materials

List of tools required for maintenance. Recommended lubricants and cleaning agents.To keep your metal lathe threading dial in top shape, you’ll need a few trusty tools. Grab a set of wrenches and screwdrivers for basic adjustments. Don’t forget the cleaning brushes for those stubborn chips that think they can camp out. For lubrication, good old-fashioned machine oil does wonders, but a quality grease can work magic too! Below is a neat little table of essentials:

| Tool/Material | Purpose |

|---|---|

| Wrenches | Adjustments |

| Screwdrivers | Fastening |

| Cleaning brushes | Chip removal |

| Machine oil | Lubrication |

| Grease | Long-lasting protection |

Keeping things clean and well-oiled means your lathe can work like a charm, and who wouldn’t want that? Remember, little maintenance now saves big headaches later! Plus, your lathe will appreciate the pampering!

Daily Maintenance Checklist

Routine inspections to identify wear and tear. Cleaning procedures to keep the threading dial functional.Keeping your metal lathe threading dial in tip-top shape is important for smooth operations. Start with daily checks to spot any wear and tear. It’s like looking for missing socks; you need to catch them before they vanish! Next, clean the threading dial to prevent gunk buildup. A clean dial means better accuracy and less drama in your projects. Here’s a handy checklist:

| Task | Frequency |

|---|---|

| Inspect for wear and tear | Daily |

| Clean threading dial | Daily |

| Lubricate moving parts | Weekly |

| Check standard settings | Weekly |

Following this checklist will keep your lathe happy and running smoothly. Remember, a little maintenance can save you from big headaches later!

Weekly and Monthly Maintenance Tasks

Detailed actions to take for extended upkeep. Signs that indicate a need for immediate attention.To keep your metal lathe running smoothly, it’s important to perform weekly and monthly maintenance tasks. Check the oil level and clean the machine to avoid dust build-up. Sharp tools increase accuracy, so inspect and replace them as needed. Look for signs like unusual noises or rough operation, which indicate that it’s time for repairs. Regular maintenance not only improves performance but also extends the life of your lathe.

What are the key maintenance tasks for a metal lathe?

Weekly tasks: Check oil levels, clean surfaces, and inspect tools.

Monthly tasks:

- Lubricate moving parts.

- Check belts and adjust tension.

- Examine electrical connections.

Troubleshooting Common Issues

Identifying symptoms of faulty threading dials. Solutions for addressing common problems.Sometimes, the threading dial on your metal lathe can act up. Symptoms of issues include a dial that won’t turn or skips numbers. These problems can cause mistakes while working on projects. Luckily, there are simple fix-it steps. Check the dial for dirt or debris. Clean it gently. If it still won’t budge, adjust its tension. Here’s what you can do:

- Inspect for dirt and clean.

- Check the tension setting.

- Verify all connections.

By following these tips, you can keep your lathe running smoothly.

What should I do if my threading dial doesn’t turn?

First, check for any dirt or blockages. Clean the dial carefully. If it remains stuck, adjust the tension to see if that helps. You may also look at the connections to ensure everything is tight.

Upgrading the Threading Dial

Benefits of upgrading to modern threading dials. Compatibility considerations with existing metal lathes.Upgrading to a modern threading dial can make your metal lathe feel like a shiny new toy! These dials offer better precision, making your threading tasks easier and more efficient. Imagine crafting threads so smooth, they could slide down a slide! Plus, many newer dials are designed to fit old lathes, which saves you the trouble of buying a whole new machine.

| Benefits | Compatibility |

|---|---|

| Increased Accuracy | Many modern dials fit older models. |

| User-Friendly Design | Retrofitting options are often available. |

| Improved Durability | Check dimensions before purchasing. |

So, if your old threading dial is feeling a bit wobbly, consider upgrading. It can make a world of difference in your projects! Remember, it’s all about threading with ease and having fun while doing it!

Maintaining Precision Settings

Techniques for ensuring precise dial settings. Importance of calibration and checks.Keeping those dial settings on point is like being a perfectionist chef, right? You want every measurement to be just right! Start by checking your dials regularly, like checking if your cereal is actually crunchy. Calibration is crucial. This ensures everything is lined up nicely and ready to go. Not calibrating can lead to mistakes, like trying to wear shoes three sizes too big – not fun! To help, here’s a quick reference table:

| Check Point | Frequency | Notes |

|---|---|---|

| Initial Calibration | Every Use | Ensure accuracy right from the start! |

| Weekly Checks | Weekly | Keep it steady and stable! |

| Deep Cleaning | Monthly | Prevent dust from crashing the party! |

Regular maintenance keeps your metal lathe running smoothly and prevents those pesky surprises. Remember, a well-maintained tool is happier, and you’ll have a better experience. Like they say, “A happy lathe makes happy threads!”

Safety Considerations During Maintenance

Essential safety gear for maintenance tasks. Best practices to avoid accidents while servicing the threading dial.Safety is key during maintenance tasks. Always wear proper gear to protect yourself. Essential items include:

- Safety goggles – Protects your eyes from debris.

- Gloves – Keeps your hands safe from cuts.

- Ear protection – Reduces noise exposure.

- Steel-toed boots – Protects your feet from heavy items.

To avoid accidents while servicing the threading dial:

- Always disconnect power first.

- Keep your workspace tidy to prevent trips.

- Use tools properly and follow instructions.

- Work with a buddy when possible.

Remember, wearing safety gear can reduce injuries by 70%! Stay safe and keep those hands safe!

What is the Best Safety Gear for Maintenance?

The best safety gear includes safety goggles, gloves, ear protection, and steel-toed boots. These items help protect against common hazards during maintenance tasks.

Resources for Further Learning

Recommended books and manuals on lathe maintenance. Online forums and communities for advice and guidance.For those keen on mastering lathe maintenance, there are some great resources to explore. Books like “Lathe Fundamentals” and “The Metal Lathe” offer expert tips and tricks. They can turn your lathe into a smooth-operating machine! Want advice? Join online communities like the Machinist Forum. There, you can chat with fellow lathe lovers. Remember, it’s okay to ask questions—after all, we were all newbies once!

| Resource Type | Recommendations |

|---|---|

| Books | “Lathe Fundamentals”, “The Metal Lathe” |

| Online Forums | Machinist Forum, CNC Zone |

Conclusion

In conclusion, a maintenance guide for your metal lathe’s threading dial is essential for smooth operation. Regular checks keep your lathe in top shape. You should clean, lubricate, and calibrate it often. These simple steps improve accuracy and longevity. For more tips, you can read detailed articles or watch helpful videos online. Taking care of your tools makes all the difference!FAQs

What Are The Key Components Of A Metal Lathe Threading Dial That Require Regular Maintenance?The key parts of a metal lathe threading dial that need regular care are the gears, the dial itself, and the pointer. You should check the gears for dirt and keep them clean. Make sure the dial turns smoothly and isn’t stuck. The pointer should be clear and point accurately. Keeping these parts in good shape helps the machine work better.

How Can You Identify Signs Of Wear Or Damage In The Threading Dial Of A Metal Lathe?To check for wear or damage on the threading dial of a metal lathe, look closely at the dial. You should see if it turns easily without sticking. Check for any cracks or chips, as these mean it’s damaged. Also, listen for any strange sounds when you use it. If something doesn’t seem right, it’s best to get help from someone experienced.

What Lubricants Are Recommended For Maintaining A Metal Lathe Threading Dial, And How Often Should They Be Applied?To keep the threading dial of a metal lathe working well, you can use machine oil or light grease. These help the parts move smoothly. You should apply the lubricant every month or whenever you notice it getting dry. Always wipe off any extra oil, so it doesn’t attract dirt.

What Troubleshooting Steps Should Be Taken If The Threading Dial Is Not Functioning Correctly During Operations?If your threading dial isn’t working right, first check if it’s properly attached. You can unscrew it and screw it back on tightly. Next, look for any dirt or dust around the dial and clean it carefully. Make sure the machine is set to the right settings for threading. If it still doesn’t work, ask an adult for help.

Are There Specific Techniques For Aligning The Threading Dial To Ensure Accurate Threading On A Metal Lathe?Yes, there are simple steps to align the threading dial on a metal lathe. First, turn the lathe on and let it spin. Then, move the tool close to the workpiece. When the threading dial shows the right number, you can start cutting. Always check that the dial is set correctly before you begin. This helps make sure your threads are accurate!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Key Components Of A Metal Lathe Threading Dial That Require Regular Maintenance? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The key parts of a metal lathe threading dial that need regular care are the gears, the dial itself, and the pointer. You should check the gears for dirt and keep them clean. Make sure the dial turns smoothly and isn’t stuck. The pointer should be clear and point accurately. Keeping these parts in good shape helps the machine work better.”}},{“@type”: “Question”,”name”: “How Can You Identify Signs Of Wear Or Damage In The Threading Dial Of A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To check for wear or damage on the threading dial of a metal lathe, look closely at the dial. You should see if it turns easily without sticking. Check for any cracks or chips, as these mean it’s damaged. Also, listen for any strange sounds when you use it. If something doesn’t seem right, it’s best to get help from someone experienced.”}},{“@type”: “Question”,”name”: “What Lubricants Are Recommended For Maintaining A Metal Lathe Threading Dial, And How Often Should They Be Applied? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep the threading dial of a metal lathe working well, you can use machine oil or light grease. These help the parts move smoothly. You should apply the lubricant every month or whenever you notice it getting dry. Always wipe off any extra oil, so it doesn’t attract dirt.”}},{“@type”: “Question”,”name”: “What Troubleshooting Steps Should Be Taken If The Threading Dial Is Not Functioning Correctly During Operations? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If your threading dial isn’t working right, first check if it’s properly attached. You can unscrew it and screw it back on tightly. Next, look for any dirt or dust around the dial and clean it carefully. Make sure the machine is set to the right settings for threading. If it still doesn’t work, ask an adult for help.”}},{“@type”: “Question”,”name”: “Are There Specific Techniques For Aligning The Threading Dial To Ensure Accurate Threading On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, there are simple steps to align the threading dial on a metal lathe. First, turn the lathe on and let it spin. Then, move the tool close to the workpiece. When the threading dial shows the right number, you can start cutting. Always check that the dial is set correctly before you begin. This helps make sure your threads are accurate!”}}]}