Have you ever watched a metal lathe in action? It’s fascinating! These machines shape metal with great precision. One key part of that accuracy is the metal lathe carriage stop clamp. This small device plays a big role.

Imagine trying to cut metal and getting it wrong. A simple mistake can ruin the whole project! The carriage stop clamp helps prevent that. It secures the carriage in place, making sure every cut is just right.

Did you know that using a lathe without a reliable stop clamp can lead to accidents? It’s true! This simple tool can save time and keeps you safe. As we explore the world of metalworking, let’s dive deeper into the metal lathe carriage stop clamp. Who knew such a small item could make such a huge difference?

Metal Lathe Carriage Stop Clamp: Essential Tool Guide

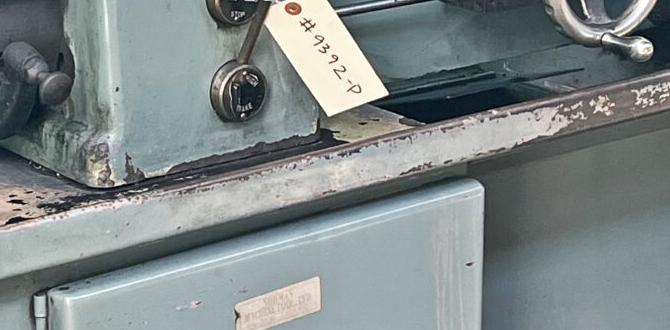

Metal Lathe Carriage Stop Clamp

A metal lathe carriage stop clamp is essential for precision in machining. This tool helps keep the workpiece steady while shaping it. By using a carriage stop, you can save time and create more consistent results. Have you ever struggled to make the same cut twice? This clamp solves that problem! It’s simple to adjust and can be used on many lathe machines. With this tool, your projects will look more professional.Understanding the Metal Lathe Carriage Stop Clamp

Definition and purpose of a carriage stop clamp. Importance in precision machining.A metal lathe carriage stop clamp holds the carriage in place. It prevents unwanted movement during machining. This tool is very important for precision machining. With a clamp, you can create accurate cuts every time. Without it, you might make mistakes that ruin your work. A stop clamp helps you work faster and better, improving the quality of your finished pieces.

What is the purpose of a carriage stop clamp?

The purpose of a carriage stop clamp is to keep the lathe carriage still. It allows you to make precise measurements and cuts. With this tool, every part you create fits perfectly.

Why is it important for precision machining?

- Accuracy: Ensures exact measurements.

- Consistency: Produces similar parts each time.

- Efficiency: Saves time by reducing mistakes.

How to Choose the Right Carriage Stop Clamp

Factors to consider: size, material, compatibility. Tips for selecting based on specific projects or needs.Choosing the right carriage stop clamp can feel like picking a snack at a candy store. It’s important to look at a few factors. First, consider the size—it should fit your lathe nicely. Then, think about the material; metal clamps are super durable! Lastly, make sure it’s compatible with your machine. If you’re working on a special project, choose a clamp that meets your needs. A good rule of thumb: if it doesn’t fit, it shouldn’t sit!

| Factor | Why It Matters |

|---|---|

| Size | A proper fit means better control! |

| Material | Durable materials last longer and handle pressure. |

| Compatibility | Ensure it matches your lathe model for best results. |

Installation Guidelines for Metal Lathe Carriage Stop Clamps

Stepbystep instructions for installation. Common mistakes to avoid.Installing a metal lathe carriage stop clamp is simple, but it’s easy to make silly mistakes! First, secure the clamp on the lathe bed. Make sure to line it up properly. Next, tighten the screws, but don’t go crazy—strip screws are no fun! Common blunders include skipping the instructions and not checking the clamp’s position before use. Remember, double-checking saves headaches later! Use the table below for quick reminders:

| Step | Tip |

|---|---|

| 1 | Secure the clamp tightly. |

| 2 | Align it properly to avoid mistakes. |

| 3 | Check the screws to prevent stripping. |

Now you’re ready to make some precise cuts! Happy lathe-ing!

Adjusting and Calibrating Your Carriage Stop Clamp

Techniques for precise adjustments. Tools needed for calibration.To adjust your metal lathe carriage stop clamp accurately, start with a few basic techniques. First, use clear measurements. Mark your desired stopping point clearly. Second, tighten the clamp firmly to ensure stability. You want it to stay in place while you work. For calibration, gather these tools:

- Ruler or calipers

- Wrench

- Marker

These tools will help you make precise adjustments. Remember, careful calibration leads to better results in your projects.

What techniques help in adjusting a carriage stop clamp?

To adjust a carriage stop clamp effectively, use clear measurements and stable tightening techniques.

Maintenance Tips for Longevity

Best practices for keeping the clamp in optimal condition. Signs of wear and when to replace.Keeping the clamp in good shape is important. Regularly check it for any signs of damage. Clean it often to remove dirt and debris. Lubricate moving parts to ensure smooth operation. Replacing parts when needed can save you trouble later. Watch for these signs:

- Cracks or breaks on the surface

- Difficulty in tightening or loosening

- Unusual noises during operation

Taking these steps helps your metal lathe carriage stop clamp last longer.

What are signs that my clamp needs replacing?

Look for cracks or tightness issues. If you notice any wear, it’s time for a new clamp. Replacements ensure safety and optimal performance.

Troubleshooting Common Issues

Identifying frequent problems and solutions. Tips for preventing issues in the future.Common issues with equipment can be frustrating. Luckily, many problems have easy fixes. Here are some frequent issues you may face with your metal lathe carriage stop clamp:

- Clamp not holding tight: Check for wear on the clamp’s surface.

- Misalignment: Ensure everything is set correctly before use.

- Rust buildup: Clean regularly to avoid friction.

To prevent future headaches, keep your tools clean and lubricated. Regular maintenance can save you from bigger problems later on!

What to do if the clamp isn’t working?

If the clamp isn’t working properly, first check how it’s attached. Make sure it’s secure. Try cleaning it and adjusting any loose parts. A well-maintained clamp can last a long time!

Expert Tips for Enhanced Performance

Insights from seasoned machinists. Advanced techniques for improved accuracy and efficiency.Improving the performance of your lathe can be simple with tips from experienced machinists. First, always keep your tools sharp. Dull tools slow you down, and nobody likes a slowpoke! Next, let precision be your best buddy. Use a metal lathe carriage stop clamp to ensure consistent cuts. This little gadget is like a trusty sidekick, helping you maintain accuracy.

| Tip | Description |

|---|---|

| Sharp tools | Keep your tools well-maintained for better results. |

| Use a clamp | A carriage stop clamp helps achieve precise measurements. |

Remember, practice makes perfect. And don’t forget to have fun while you create! After all, happy machining leads to happy products!

Conclusion

In summary, a metal lathe carriage stop clamp is a useful tool for precise machining. It helps you maintain accuracy while cutting materials. Understanding how to use it can improve your projects significantly. We encourage you to explore tutorials or guides to see it in action. Practice using the clamp, and you’ll become more skilled and confident in your metalworking.FAQs

What Is The Purpose Of A Carriage Stop Clamp On A Metal Lathe And How Does It Enhance Precision In Machining?A carriage stop clamp is used on a metal lathe to help you make cuts at exactly the right spot. It holds the sliding part of the machine in place. This means you can repeat your cuts perfectly without guessing. By using the clamp, we get cleaner and more precise work, which is very important when making parts.

How Do You Properly Adjust A Carriage Stop Clamp To Ensure Consistent Workpiece Length During Lathe Operations?To adjust the carriage stop clamp, first, measure the length you want for your workpiece. Then, slide the clamp to that mark and tighten it securely. Make sure it doesn’t move by giving it a gentle pull. After that, you can start your lathe and check the length of the first piece. If it’s not right, adjust the clamp again until it is perfect.

What Materials Are Commonly Used To Manufacture Carriage Stop Clamps, And What Factors Should Be Considered When Selecting A Material?Carriage stop clamps are usually made from metal, like steel or aluminum. Sometimes, they can be made from strong plastic. When choosing a material, we should think about how strong it needs to be and if it will rust or break. We also need to consider the weight and cost of the material.

Can A Carriage Stop Clamp Be Used With Different Sizes Of Metal Lathes, And What Adjustments Need To Be Made For Compatibility?Yes, you can use a carriage stop clamp on different sizes of metal lathes. First, check the size of the clamp and the lathe. You may need to adjust the clamp to fit properly. Sometimes, you will loosen or tighten screws to make it fit just right. Always make sure it is secure before you start working.

What Are Some Common Issues That Can Arise With Carriage Stop Clamps, And How Can They Be Effectively Resolved During Use?Carriage stop clamps can sometimes get stuck or not hold tight. If they’re stuck, try wiggling them gently to loosen them. If they don’t hold, check if they’re installed correctly and tighten the screws. You can also clean them to remove dirt. With a little care, we can keep them working well!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Is The Purpose Of A Carriage Stop Clamp On A Metal Lathe And How Does It Enhance Precision In Machining? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A carriage stop clamp is used on a metal lathe to help you make cuts at exactly the right spot. It holds the sliding part of the machine in place. This means you can repeat your cuts perfectly without guessing. By using the clamp, we get cleaner and more precise work, which is very important when making parts.”}},{“@type”: “Question”,”name”: “How Do You Properly Adjust A Carriage Stop Clamp To Ensure Consistent Workpiece Length During Lathe Operations? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To adjust the carriage stop clamp, first, measure the length you want for your workpiece. Then, slide the clamp to that mark and tighten it securely. Make sure it doesn’t move by giving it a gentle pull. After that, you can start your lathe and check the length of the first piece. If it’s not right, adjust the clamp again until it is perfect.”}},{“@type”: “Question”,”name”: “What Materials Are Commonly Used To Manufacture Carriage Stop Clamps, And What Factors Should Be Considered When Selecting A Material? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Carriage stop clamps are usually made from metal, like steel or aluminum. Sometimes, they can be made from strong plastic. When choosing a material, we should think about how strong it needs to be and if it will rust or break. We also need to consider the weight and cost of the material.”}},{“@type”: “Question”,”name”: “Can A Carriage Stop Clamp Be Used With Different Sizes Of Metal Lathes, And What Adjustments Need To Be Made For Compatibility? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, you can use a carriage stop clamp on different sizes of metal lathes. First, check the size of the clamp and the lathe. You may need to adjust the clamp to fit properly. Sometimes, you will loosen or tighten screws to make it fit just right. Always make sure it is secure before you start working.”}},{“@type”: “Question”,”name”: “What Are Some Common Issues That Can Arise With Carriage Stop Clamps, And How Can They Be Effectively Resolved During Use? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Carriage stop clamps can sometimes get stuck or not hold tight. If they’re stuck, try wiggling them gently to loosen them. If they don’t hold, check if they’re installed correctly and tighten the screws. You can also clean them to remove dirt. With a little care, we can keep them working well!”}}]}