Metal Lathe Chip Control Methods: Effective Strategies Explained

Metal Lathe Chip Control Methods

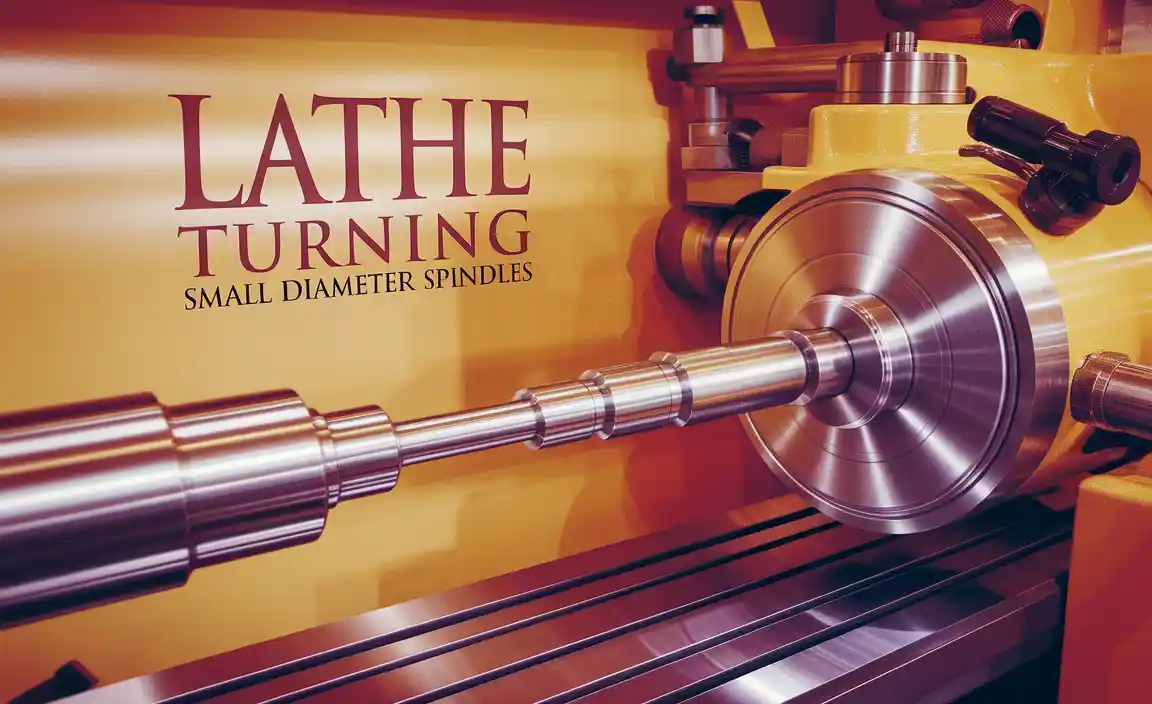

Metal lathe chip control methods are essential for creating a clean workspace. When you machine metal, chips fly everywhere. Have you ever seen a messy workshop? It can be dangerous! You’ll learn about different techniques to manage those flying chips. Methods include using chip conveyors and various coolant systems to keep things tidy. Did you know that effective chip control can also enhance your machining accuracy? Cleaner work areas lead to better results!Understanding Chip Formation

Different types of chips produced in turning operations. Factors influencing chip formation, such as material and cutting speed.In turning operations, different types of chips form from the metal. Some chips are thin and curly, while others are thick and short. These shapes depend on several factors, like the material of the metal and the cutting speed. Here are key influences:

- Material: Softer metals may produce different chips than harder ones.

- Cutting Speed: Faster speeds can create finer chips.

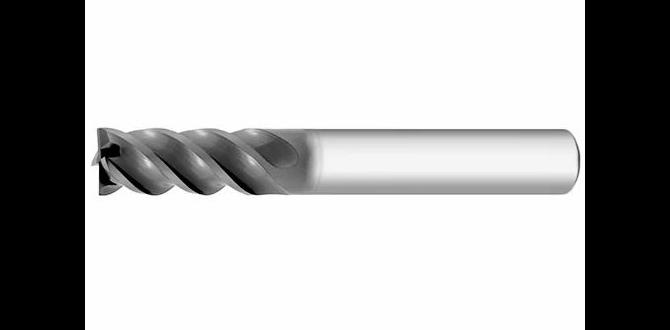

- Tool Shape: A sharp tool can also influence chip formation.

Understanding these factors helps in controlling the chips better.

What are the different types of chips?

Metal chips can vary from fine, long curls to thick, rough ones depending on cutting conditions.

How does cutting speed affect chips?

Higher cutting speeds usually create thinner chips and reduce tool wear.

Importance of Chip Control

Impact on surface finish and tool life. Safety considerations in chip management.Properly managing chips is important for quality work. It can affect the surface finish of your project and help tools last longer. Good chip control methods keep the work area safe. Uncontrolled chips can cause injuries. So, handling them wisely is smart. Here are key points to remember:

- Surface Finish: Fewer chips lead to smoother surfaces.

- Tool Life: Less wear on tools means they last longer.

- Safety: Keeping chips in check prevents slips and cuts.

Why is chip control important?

It helps produce high-quality finishes and keeps tools in good shape while ensuring a safe workspace. Proper control methods lead to better results in less time.

Common Chip Control Methods

Manual chip removal techniques. Use of chip trays and collection systems.Keeping chips under control is important for smooth and safe metal lathe work. One method is using manual chip removal. This means workers often pause to clean up chips by hand. Another method is using chip trays. These trays catch chips as they fall. Some machines even have collection systems that automatically remove chips. This keeps the workspace clean and helps machines run better.

What are manual chip removal techniques?

Manual chip removal techniques involve stopping the machine to clear away chips by hand. This method helps keep your workspace tidy and safe.

What tools are used for chip control?

- Chip shovels

- Brooms

- Vacuum systems

How do chip trays and collection systems work?

Chip trays collect falling chips, while collection systems remove them automatically. These tools help avoid accidents and keep machines running smoothly.

Chemical Lubricants and Their Role

Types of cutting fluids for effective chip control. How lubricants influence chip formation and removal.Chemicals can help when using a metal lathe. Cutting fluids are key. They cool and lubricate the area where the metal is cut. Here are common types:

- Water-Soluble Oils: These mix with water. They cool well.

- Mineral Oils: These are thicker. They help with lubrication.

- Synthetic Fluids: These are made from chemicals. They are effective and good for the environment.

Good lubricants change how chips form and come off the metal. Proper chip control means less mess, safer work, and better products. They make cutting smoother and faster. This leads to better finishing on items made from metal.

How do lubricants help with chip control?

Lubricants help chip removal by reducing friction. This makes chips easier to separate from the metal. When lubrication is right, chips won’t jam or stick.

Innovative Technologies for Chip Control

Smart lathe systems and realtime monitoring. Use of sensors and AI in predicting chip behavior.New technologies help control chips more effectively in metal lathes. Smart lathe systems can track chip formation in real time. They use sensors to gather data and advanced AI to predict what chips will do next. This means better performance and less waste. By making changes based on this data, operators can improve safety and produce better parts quickly.

How do sensors and AI work together in chip control?

Sensors collect data on chip flow, while AI analyzes that data to predict problems before they happen. This helps workers take action quickly. It creates a safer and more efficient work environment.

- Real-time tracking of chip behavior

- Predicts and prevents issues

- Improves efficiency in production

Best Practices for Chip Management

Maintenance routines for chip control systems. Ergonomic considerations for operators handling chips.Proper maintenance is key for chip control systems. Regularly clean and check equipment for any wear. This keeps everything running smoothly and prevents chip buildup. Don’t forget ergonomic tips for operators! Use tools that help lift or navigate chips easily. This makes working more comfortable and safe. Remember, a happy worker is a productive worker, and no one wants to wrestle with a pile of metal shavings!

| Maintenance Routine | Ergonomic Tip |

|---|---|

| Regular cleaning | Use chip trays for easy disposal |

| Inspect for wear | Choose tools that suit your height |

| Lubricate machines | Take breaks and stretch |

Case Studies and Real-World Applications

Examples of successful chip control implementation in industries. Lessons learned from companies in managing metal chips.Many industries have successfully controlled metal chips, improving safety and efficiency. For example, a car manufacturing plant used strong vacuum systems to capture chips. This led to less cleanup time and fewer accidents. Here are some lessons learned:

- Invest in technology to streamline processes.

- Train workers to understand chip management.

- Regularly maintain equipment to ensure peak performance.

These examples show that smart chip control is not just good for business; it also keeps people safe!

What are effective chip control methods?

Effective chip control methods include using chip conveyors, vacuum systems, and coolant management. These methods help maintain a clean workplace and improve productivity.

Conclusion

In summary, effective chip control is crucial for using a metal lathe safely and efficiently. You can manage chips by adjusting tool height, using coolant, and maintaining proper speeds. Experiment with these methods to find what works best for you. For more details, consider reading guides or watching videos on metal lathe techniques. Happy machining!FAQs

Here Are Five Questions Related To Metal Lathe Chip Control Methods:Sure! Here’s a short answer related to chip control on a metal lathe: When you use a metal lathe, it makes small bits called chips. To keep these chips in control, we can use special tools or fans to blow them away. We also can change how fast the lathe spins to cut smoothly. Keeping the area clean helps us see better and prevents accidents with the chips. It’s important to manage these chips for safety and to make good parts!

Sure! Please provide the question you want me to answer.

What Are The Most Effective Chip Control Methods For Reducing Chip Buildup During The Turning Process On A Metal Lathe?To stop chips from piling up on a metal lathe, we can do a few things. First, you should use a good cutting tool made for the job. Next, adjusting the speed can help keep chips from getting stuck. You can also use coolant, which helps cool the metal and makes chips easier to move away. Lastly, changing the tool’s angle can help chips break off better.

How Do Coolant And Lubrication Systems Impact Chip Control And Removal In Metal Lathe Operations?Coolant and lubrication systems help keep the metal lathe cool and smooth. They make cutting easier, so chips, which are tiny pieces of metal, come off quickly. This helps us make better shapes without breaking tools. When we have good coolant, it also washes away the chips, keeping our workspace clean. This makes working safer and faster!

What Role Does Tooling Geometry Play In The Formation And Management Of Chips In Lathe Machining?Tooling geometry is the shape and angles of the cutting tools we use on a lathe. It helps decide how the metal gets cut and how chips, or small pieces of metal, are formed. If the tool is designed well, it makes chips easier to handle and reduces the chance of problems. Good tooling geometry also makes machining faster and cleaner. When we use the right shapes, we can have better results in our work.

How Can Automated Chip Disposal Systems Improve Efficiency In High-Volume Metal Lathe Machining Environments?Automated chip disposal systems help us work faster in metal lathe machining. They quickly remove metal scraps, so we don’t have to stop and clean. This saves time and keeps our machines running smoothly. When we have less mess, we can make more parts and do a better job!

What Specific Challenges Are Associated With Chip Control When Machining Different Materials, Such As Aluminum Versus Steel, On A Lathe?When we machine materials like aluminum and steel, we face different challenges with chips. Aluminum makes big, fluffy chips that can get stuck. Steel creates smaller, sharper chips that can fly away quickly. We need to use the right tools and speeds to manage these chips well. If we don’t control the chips, they can make our work harder and mess things up.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Here Are Five Questions Related To Metal Lathe Chip Control Methods:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here’s a short answer related to chip control on a metal lathe: When you use a metal lathe, it makes small bits called chips. To keep these chips in control, we can use special tools or fans to blow them away. We also can change how fast the lathe spins to cut smoothly. Keeping the area clean helps us see better and prevents accidents with the chips. It’s important to manage these chips for safety and to make good parts!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you want me to answer.”}},{“@type”: “Question”,”name”: “What Are The Most Effective Chip Control Methods For Reducing Chip Buildup During The Turning Process On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To stop chips from piling up on a metal lathe, we can do a few things. First, you should use a good cutting tool made for the job. Next, adjusting the speed can help keep chips from getting stuck. You can also use coolant, which helps cool the metal and makes chips easier to move away. Lastly, changing the tool’s angle can help chips break off better.”}},{“@type”: “Question”,”name”: “How Do Coolant And Lubrication Systems Impact Chip Control And Removal In Metal Lathe Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Coolant and lubrication systems help keep the metal lathe cool and smooth. They make cutting easier, so chips, which are tiny pieces of metal, come off quickly. This helps us make better shapes without breaking tools. When we have good coolant, it also washes away the chips, keeping our workspace clean. This makes working safer and faster!”}},{“@type”: “Question”,”name”: “What Role Does Tooling Geometry Play In The Formation And Management Of Chips In Lathe Machining?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Tooling geometry is the shape and angles of the cutting tools we use on a lathe. It helps decide how the metal gets cut and how chips, or small pieces of metal, are formed. If the tool is designed well, it makes chips easier to handle and reduces the chance of problems. Good tooling geometry also makes machining faster and cleaner. When we use the right shapes, we can have better results in our work.”}},{“@type”: “Question”,”name”: “How Can Automated Chip Disposal Systems Improve Efficiency In High-Volume Metal Lathe Machining Environments?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Automated chip disposal systems help us work faster in metal lathe machining. They quickly remove metal scraps, so we don’t have to stop and clean. This saves time and keeps our machines running smoothly. When we have less mess, we can make more parts and do a better job!”}},{“@type”: “Question”,”name”: “What Specific Challenges Are Associated With Chip Control When Machining Different Materials, Such As Aluminum Versus Steel, On A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When we machine materials like aluminum and steel, we face different challenges with chips. Aluminum makes big, fluffy chips that can get stuck. Steel creates smaller, sharper chips that can fly away quickly. We need to use the right tools and speeds to manage these chips well. If we don’t control the chips, they can make our work harder and mess things up.”}}]}