Have you ever watched a metal lathe in action? It’s fascinating to see how it shapes metal into perfect designs. But did you know that safety is just as important as skill when using one? Installing a metal lathe chip guard is a smart move for any workshop. It helps keep you safe from flying chips and debris.

Imagine standing in front of a spinning metal piece. Suddenly, a sharp chip flies out. Ouch, right? That’s where a chip guard steps in. It acts like a shield, protecting you from harm. In our article, we’ll guide you through the simple steps of metal lathe chip guard installation. You’ll learn the easy tricks to keep your workspace safe and clean.

Many people overlook this important part of their metal lathe setup. But here’s a fun fact: a simple guard can prevent serious injuries. Why take the risk? Let’s explore how you can add a layer of safety to your lathe today!

Metal Lathe Chip Guard Installation: A Step-By-Step Guide

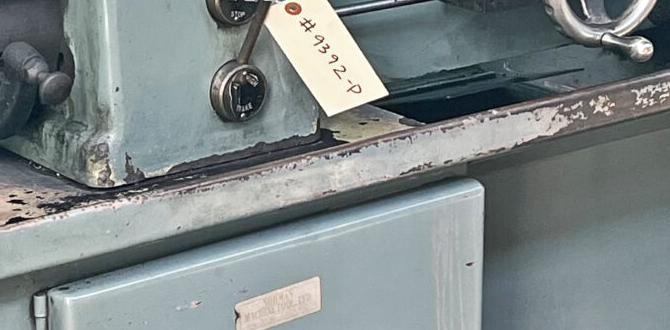

Metal Lathe Chip Guard Installation

Installing a metal lathe chip guard is key to safety. Chip guards protect you from flying debris that can cause injury. First, gather all necessary tools and materials. Then, carefully follow your lathe’s manual for specific guidelines. Did you know that proper installation can extend the life of your equipment? A well-fitted guard helps ensure improved visibility and safety. This simple step can make your workspace much safer and more efficient.Types of Chip Guards Available

Description of various types (e.g., fixed, adjustable, removable). Pros and cons of each type for different lathe models.Chip guards come in a few frosty flavors! We have fixed, adjustable, and removable options dancing in the spotlight. Fixed chip guards stay in one spot, providing solid protection without fuss. But can be a little snug for some machines. Adjustable chip guards are the gymnasts of the group. They can bend and twist to fit your lathe, but they might wobble during wild projects. Finally, removable chip guards give you a break when setting up. Just pop them off! But be careful—they can play hide and seek! Here’s a quick look at their pros and cons:

| Type | Pros | Cons |

|---|---|---|

| Fixed | Steady protection | Limited flexibility |

| Adjustable | Customizable fit | Can be unstable |

| Removable | Easy access | Risk of misplacing |

Choosing the right type depends on your lathe model and how much fun (or mischief) you’re planning to have!

Step-by-Step Installation Process

Detailed instructions for installing a fixed chip guard. Detailed instructions for installing an adjustable chip guard.To install a fixed chip guard, follow these steps:

- Measure the lathe’s dimensions.

- Cut the chip guard to fit.

- Secure the guard using screws or brackets.

- Check that the guard covers the working area well.

For an adjustable chip guard, use these instructions:

- Start by measuring the needed height and width.

- Cut the material accordingly.

- Attach hinges to allow movement.

- Fix the guard at a safe height but still easy to adjust.

What tools are needed for installation?

You need a screwdriver, measuring tape, and a saw for both chip guards. Keep them handy for a smooth installation process!

Common Mistakes to Avoid During Installation

Identification of frequent pitfalls and errors. Tips for troubleshooting and ensuring a successful installation.Installing a metal lathe chip guard can be tricky. Many people face common mistakes during the process. Some errors include:

- Not measuring parts accurately

- Forgetting to secure screws tightly

- Ignoring safety features

To troubleshoot, double-check everything. Make sure you follow the instructions carefully. If something doesn’t fit, reassess your measurements. Remember, careful planning leads to a successful installation!

What are frequent mistakes during installation?

Some common mistakes are missing parts, incorrect measurements, and not securing guards well. Double-check your tools and parts before starting.

Tips for successful installation:

- Read the manual completely.

- Use the right tools for each job.

- Ask for help if unsure.

Maintenance and Care for Your Chip Guard

Guidelines for regular maintenance of the chip guard. Tips for cleaning and inspecting the chip guard for damage.Taking care of your chip guard is like caring for a tiny robot bodyguard. It can protect you well if maintained properly! Regular checks are essential. Clear off any chips or dirt. A simple wipe with a cloth can do wonders. Inspect for cracks or bends; even tiny ones matter! If something looks wrong, get it fixed fast—no one wants flying metal bits! Remember, a clean guard is a happy guard! Your safety is worth it!

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Wipe down the guard | Weekly | Use a dry cloth |

| Inspect for damage | Monthly | Look for cracks or bends |

| Replace worn parts | As needed | Don’t delay if damaged |

Questions pop up! How long should a chip guard last? Well, with great care, many guards can last for years—like a trusty friend! Who wouldn’t want that?

Safety Considerations When Using a Chip Guard

Discussion of safety standards and guidelines for metal lathe operation. Importance of following safety practices while using the chip guard.Keeping safe while using a metal lathe is very important. Following safety rules helps prevent accidents and injuries. A chip guard is a key safety tool. It protects you from flying debris. Everyone using a lathe needs to follow these simple guidelines:

- Wear safety goggles to protect your eyes.

- Keep hands and loose clothing away from moving parts.

- Always check that the chip guard is installed correctly.

- Follow operation guidelines in the user manual.

Remember, safety comes first. If everyone follows these practices, we can enjoy a safer work environment.

What are essential safety practices for metal lathe operation?

The best practices include using a chip guard, wearing protective gear, and keeping the workspace tidy. This ensures the safety of all operators and bystanders.

Frequently Asked Questions (FAQs)

Common queries about chip guard installation and usage. Expert answers to address concerns and misconceptions.Installing a chip guard might seem tricky, but it’s a breeze with the right info! People often wonder, “Do I really need a chip guard?” The answer is a cheerful yes! It keeps those pesky chips from flying into your eyes or coffee. Another common question is, “Will it fit my machine?” Usually, chip guards can be adjusted to fit most metal lathes. Now, let’s clear up some confusion with a handy table!

| Question | Answer |

|---|---|

| Do I need special tools? | Nope! Regular tools will do! |

| Can I install it myself? | Absolutely, it’s DIY friendly! |

| How often do I need to check it? | Give it a look every few projects! |

Easy peasy, right? Now you can work safely and maybe even enjoy a few flying chips without worry!

Conclusion

In conclusion, installing a metal lathe chip guard is crucial for safety and cleanliness. You protect yourself from flying chips and dust. Follow the instructions carefully for the best results. Always check your guard’s fit and condition. We encourage you to read guides or watch videos for further tips. Stay safe and enjoy using your lathe!FAQs

What Are The Essential Safety Features To Consider When Selecting A Chip Guard For A Metal Lathe?When picking a chip guard for a metal lathe, you should look for a few important safety features. First, it should block flying metal chips so they don’t hurt you. Second, it must be strong and sturdy to protect you while you work. Lastly, the guard should be easy to see through, so you can keep an eye on what you’re doing. Always choose a guard that fits your machine well!

How Should The Chip Guard Be Positioned To Ensure Optimal Safety And Visibility During Lathe Operation?To keep safe while using a lathe, you should position the chip guard close to the machine. Make sure it covers your work area well. This way, it blocks flying chips but still lets you see what you’re doing. Always check that it is secure before starting the machine. Remember, safety first!

What Materials Are Recommended For Constructing A Durable And Effective Chip Guard For A Metal Lathe?For a chip guard on a metal lathe, you can use clear plastic or tough acrylic. These materials protect you from flying metal bits. Make sure it’s thick enough, like 1/4 inch, so it won’t break easily. You can also use metal frames for extra strength. Don’t forget to attach it securely so it stays in place!

What Steps Should Be Taken During The Installation Process To Ensure That The Chip Guard Does Not Interfere With The Lathe’S Functionality?To install the chip guard correctly, start by reading the instructions carefully. Make sure you have all the tools you need. Then, check that the lathe can still move freely. Finally, test it before use to ensure everything works well together. This way, you can keep safe while using the lathe.

Are There Specific Maintenance Practices That Should Be Followed To Keep The Chip Guard In Good Condition And Ensure Its Effectiveness?Yes, we can keep the chip guard in good shape! First, we should clean it regularly to remove dirt and chips. Use a soft cloth and gentle soap. Next, check for cracks or damages. If you find any, fix them right away. Finally, make sure it fits well so it can protect you effectively.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Essential Safety Features To Consider When Selecting A Chip Guard For A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When picking a chip guard for a metal lathe, you should look for a few important safety features. First, it should block flying metal chips so they don’t hurt you. Second, it must be strong and sturdy to protect you while you work. Lastly, the guard should be easy to see through, so you can keep an eye on what you’re doing. Always choose a guard that fits your machine well!”}},{“@type”: “Question”,”name”: “How Should The Chip Guard Be Positioned To Ensure Optimal Safety And Visibility During Lathe Operation? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep safe while using a lathe, you should position the chip guard close to the machine. Make sure it covers your work area well. This way, it blocks flying chips but still lets you see what you’re doing. Always check that it is secure before starting the machine. Remember, safety first!”}},{“@type”: “Question”,”name”: “What Materials Are Recommended For Constructing A Durable And Effective Chip Guard For A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “For a chip guard on a metal lathe, you can use clear plastic or tough acrylic. These materials protect you from flying metal bits. Make sure it’s thick enough, like 1/4 inch, so it won’t break easily. You can also use metal frames for extra strength. Don’t forget to attach it securely so it stays in place!”}},{“@type”: “Question”,”name”: “What Steps Should Be Taken During The Installation Process To Ensure That The Chip Guard Does Not Interfere With The Lathe’S Functionality? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To install the chip guard correctly, start by reading the instructions carefully. Make sure you have all the tools you need. Then, check that the lathe can still move freely. Finally, test it before use to ensure everything works well together. This way, you can keep safe while using the lathe.”}},{“@type”: “Question”,”name”: “Are There Specific Maintenance Practices That Should Be Followed To Keep The Chip Guard In Good Condition And Ensure Its Effectiveness?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, we can keep the chip guard in good shape! First, we should clean it regularly to remove dirt and chips. Use a soft cloth and gentle soap. Next, check for cracks or damages. If you find any, fix them right away. Finally, make sure it fits well so it can protect you effectively.”}}]}