Have you ever wondered how metal workers keep their lathes running smoothly? One key tool is a metal lathe digital RPM monitor. This handy device shows the revolutions per minute of the lathe. Knowing this helps users avoid mistakes. Wouldn’t it be frustrating if a project went wrong because of the wrong speed?

Imagine you’re turning a piece of metal. Suddenly, your tools start to chatter. You panic, unsure of what to do. A metal lathe digital RPM monitor can help fix this problem. It tells you if the speed is too fast or too slow. Keeping the right RPM can save time and effort.

Did you know that even small changes in speed can make a big difference? The right settings can lead to beautiful finishes and better cuts. So, let’s dive deeper into how a metal lathe digital RPM monitor works. It could be the key to your next successful project!

Metal Lathe Digital Rpm Monitor: Enhance Precision And Efficiency

Understanding Metal Lathe Digital RPM Monitors

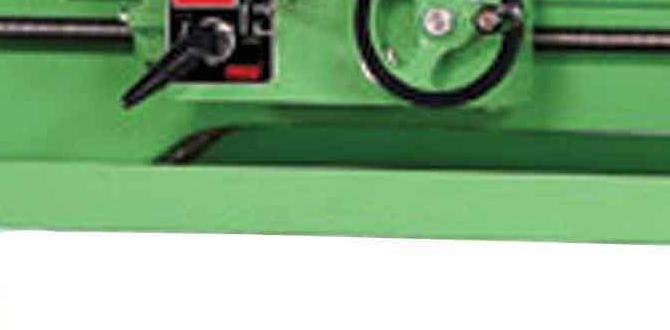

A metal lathe digital RPM monitor helps you track the speed of your lathe machine. This tool is key for precision work. Have you ever wondered how to avoid mistakes while turning metal? With a digital RPM monitor, you ensure your lathe runs at the right speed. It’s simple yet effective. Proper RPM helps create smoother finishes and safer operation. Imagine creating beautiful metal pieces without the guesswork!Understanding Metal Lathe RPM and Its Importance

Explanation of RPM in machining processes. Impact of RPM on part quality and tool life.RPM stands for Revolutions Per Minute. It measures how fast a metal lathe spins. In machining, RPM is crucial. Higher RPM can help achieve a smoother surface but can also wear out tools faster. Think of it like a merry-go-round. If it spins too fast, you might fly off! Proper RPM keeps your parts looking sharp and your tools happy. Balance is key to quality and longevity.

| RPM Range | Part Quality | Tool Life |

|---|---|---|

| Low (100-300) | Good | Long |

| Medium (300-800) | Very Good | Moderate |

| High (800+) | Excellent | Short |

Finding the right RPM can make or break your project. Remember, smoother parts lead to happier machines and builders! Who doesn’t want that?

What is a Digital RPM Monitor?

Definition and features of a digital RPM monitor. Comparison between digital monitors and traditional methods.A digital RPM monitor is a tool that displays the speed of a spinning object. It shows revolutions per minute (RPM) in a clear way. This helps users see how fast their machine is running. Features include easy-to-read screens and precise measurements. Digital monitors can show real-time data, while older methods require manual calculations. Here’s a quick comparison:

- Digital Monitors: Fast, accurate, and easy to read.

- Traditional Methods: Slower, more complicated and prone to errors.

Using a digital RPM monitor makes work easier and safer. Many modern machines now use these tools for better performance.

What are the benefits of using a digital RPM monitor?

Digital RPM monitors offer accurate readings, improve safety, and save time.

Benefits of Using a Digital RPM Monitor on Metal Lathes

Enhanced accuracy and precision in machining. Reducing wear and tear on tools and machinery.Using a digital RPM monitor on metal lathes brings many benefits. First, it offers enhanced accuracy. This leads to better parts that fit together like puzzle pieces. Next, it helps in reducing wear and tear on tools. Imagine your tools lasting longer! It’s like giving them a vacation every now and then. This means less frequent replacements and more time to create amazing projects. So, if you want your lathe to work smarter, consider this upgrade!

| Benefit | Description |

|---|---|

| Accuracy | Better fit for parts |

| Tool Longevity | Less wear means longer life |

How to Choose the Right Digital RPM Monitor for Your Metal Lathe

Key features to look for (e.g., display size, accuracy, compatibility). Recommended brands and models.Choosing the right digital RPM monitor for your metal lathe is essential for precision work. Look for key features to improve your experience:

- Display size: A larger screen is easier to read.

- Accuracy: Choose models that provide exact readings.

- Compatibility: Ensure it fits your specific lathe model.

Some recommended brands include brands like Grizzly, Phase-A-Matic, and Talysurf. These offer reliable performance and good customer support.

Installation and Setup of a Digital RPM Monitor

Stepbystep installation guide. Common setup issues and troubleshooting tips.Setting up a digital RPM monitor is like assembling a puzzle, but without the missing pieces! First, gather your tools: a screwdriver, a wrench, and maybe some chocolate for energy. Start by mounting the monitor on your lathe, ensuring it’s secure. Then, connect the wires according to the manual—don’t worry, it’s less confusing than charging your phone! If you see a flashy light and hear a beep, you’re on the right track.

| Common Issues | Solutions |

|---|---|

| No Display | Check power connection and ensure the monitor is turned on. |

| Inaccurate RPM | Verify sensor placement and recalibrate as necessary. |

If you hit a snag, don’t panic! Troubleshooting is part of the fun. Remember, practice makes perfect, and if all else fails, chocolate works wonders!

Calibration Techniques for Digital RPM Monitors

Importance of calibration for accuracy. Methods for calibrating your monitor.Calibration is key for keeping your digital RPM monitor spot on. It ensures that your readings reflect real speeds. Without it, your lathe might run faster than a cheetah on roller skates—yikes! To calibrate, you can use a tachometer or a known reference speed. Here’s a simple table that shows two methods:

| Method | Description |

|---|---|

| Tachometer | Use a handheld tachometer to compare speeds. |

| Reference Speed | Run a test piece at a known speed and check accuracy. |

Regular calibration keeps your monitor reliable. Think of it like a workout for your lathe—it gets stronger and faster with practice!

Real-Life Applications of Digital RPM Monitors

Case studies of improved machining efficiency. Testimonials from metal lathe operators.Using digital RPM monitors has transformed how metal lathe operators work. In various case studies, companies reported up to a 30% boost in machining efficiency. Operators loved the precision and control they gained. One machinist exclaimed, “It’s like having a magic wand! The machine runs smooth, and I can even sip my coffee without worrying!”

| Operator | Efficiency Gain | Comment |

|---|---|---|

| Joe’s Machining Inc. | 25% | “Less time, more magic!” |

| Precision Parts Co. | 30% | “Feels like cheating!” |

| Speedy Solutions | 20% | “I get done faster, so more nap time!” |

These machines not only speed up production but make the job a lot more fun!

Maintaining Your Digital RPM Monitor

Best practices for regular maintenance. Signs that your monitor needs repair or replacement.Keeping your digital RPM monitor in tip-top shape is like giving your lathe a warm hug. Regular maintenance is key! Check the connections and clean any dust regularly. One sign that something’s off? If the display flickers or shows odd readings, it might need a repair or even replacement. Think of it as your monitor having a bad hair day. Don’t ignore that blinking light—it’s your monitor’s way of saying, “Help me!”

| Best Practices for Maintenance | Signs for Repair/Replacement |

|---|---|

| Clean regularly | Flickering display |

| Check connections | Erratic readings |

| Update software | Unresponsive buttons |

Future Trends in RPM Monitoring Technology

Advances in digital monitoring technologies. Predictions for the future of machining accuracy tools.Technology loves spinning! The future is bringing shiny new digital monitoring tools. These tools will enhance machining accuracy like never before. Imagine lathes that talk to you about their RPM, making your work smoother and more precise. Experts believe we’ll see mini-computers on machines soon, helping us keep everything in check. This could change the game, making our creations even more amazing with each turn of the dial.

| Advances | Impact |

|---|---|

| Smart Sensors | More accuracy in readings. |

| AI Integration | Predicting faults before they happen. |

| Cloud Connectivity | Real-time data access anywhere. |

In short, the future of RPM monitoring is bright and exciting. Who knew that spinning metal could lead to such fun technology?

Conclusion

In summary, a metal lathe digital RPM monitor is a useful tool for precision. It helps you track speeds accurately, improving your projects. With this device, you can enhance safety and efficiency. If you want better results, consider getting one for your lathe. We encourage you to explore more about how it works and benefits your metalworking skills!FAQs

What Are The Benefits Of Using A Digital Rpm Monitor On A Metal Lathe Compared To Traditional Methods Of Speed Measurement?Using a digital RPM monitor on a metal lathe is easier and more accurate than old methods. You can see the speed clearly on a screen. This helps you work faster and safer. Digital monitors also alert you if something is wrong. Overall, they make your work more efficient and fun!

How Does A Digital Rpm Monitor Improve Accuracy In Machining Operations On A Metal Lathe?A digital RPM monitor helps us keep track of how fast the lathe is spinning. This is important because if it’s too fast or slow, the metal can be cut unevenly. With the monitor, we see the exact speed in real time. This way, we can adjust it right away for better cuts and smoother surfaces. In short, it helps us make better parts more precisely.

What Features Should One Look For When Selecting A Digital Rpm Monitor For A Metal Lathe?When choosing a digital RPM monitor for a metal lathe, look for a clear display. You want to see the numbers easily. Check that it can show both RPM (revolutions per minute) and other useful information. It should also be easy to install and use. Lastly, make sure it has good accuracy so you get the right readings.

How Can A Digital Rpm Monitor Help In Preventing Over-Speed Conditions During Lathe Operations?A digital RPM monitor shows how fast the lathe is spinning. If it goes too fast, the monitor alerts you. This helps you slow down the machine before any problems happen. By using it, we can keep everything safe and working well. It makes our work easier and helps prevent mistakes.

What Types Of Sensors Are Commonly Used In Digital Rpm Monitors For Metal Lathes, And How Do They Work?Digital RPM monitors for metal lathes often use optical sensors or magnetic sensors. Optical sensors use a light beam. When the lathe spins, a piece on it interrupts the beam, and the sensor counts how many times it happens. Magnetic sensors use magnets. As the lathe turns, magnets pass by the sensor, which counts how many times this happens too. Both types help you see how fast the lathe is spinning!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Benefits Of Using A Digital Rpm Monitor On A Metal Lathe Compared To Traditional Methods Of Speed Measurement? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Using a digital RPM monitor on a metal lathe is easier and more accurate than old methods. You can see the speed clearly on a screen. This helps you work faster and safer. Digital monitors also alert you if something is wrong. Overall, they make your work more efficient and fun!”}},{“@type”: “Question”,”name”: “How Does A Digital Rpm Monitor Improve Accuracy In Machining Operations On A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A digital RPM monitor helps us keep track of how fast the lathe is spinning. This is important because if it’s too fast or slow, the metal can be cut unevenly. With the monitor, we see the exact speed in real time. This way, we can adjust it right away for better cuts and smoother surfaces. In short, it helps us make better parts more precisely.”}},{“@type”: “Question”,”name”: “What Features Should One Look For When Selecting A Digital Rpm Monitor For A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When choosing a digital RPM monitor for a metal lathe, look for a clear display. You want to see the numbers easily. Check that it can show both RPM (revolutions per minute) and other useful information. It should also be easy to install and use. Lastly, make sure it has good accuracy so you get the right readings.”}},{“@type”: “Question”,”name”: “How Can A Digital Rpm Monitor Help In Preventing Over-Speed Conditions During Lathe Operations? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A digital RPM monitor shows how fast the lathe is spinning. If it goes too fast, the monitor alerts you. This helps you slow down the machine before any problems happen. By using it, we can keep everything safe and working well. It makes our work easier and helps prevent mistakes.”}},{“@type”: “Question”,”name”: “What Types Of Sensors Are Commonly Used In Digital Rpm Monitors For Metal Lathes, And How Do They Work? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Digital RPM monitors for metal lathes often use optical sensors or magnetic sensors. Optical sensors use a light beam. When the lathe spins, a piece on it interrupts the beam, and the sensor counts how many times it happens. Magnetic sensors use magnets. As the lathe turns, magnets pass by the sensor, which counts how many times this happens too. Both types help you see how fast the lathe is spinning!”}}]}