Have you ever watched a metal lathe spin and thought about safety? It can be fascinating but also dangerous. A metal lathe is a powerful tool that shapes metal into amazing pieces. However, it can cause accidents if not handled with care.

Imagine working on a project and suddenly something goes wrong. The machine starts making strange noises, and you feel panic rise. What do you do? This is where the metal lathe emergency stop guide comes into play.

Knowing how to stop a metal lathe quickly can save you from harm. It’s essential to learn the right steps. Did you know that most accidents happen because people don’t know how to react? This guide will help you gain confidence and stay safe while working.

So, are you ready to learn how to protect yourself and others when using a metal lathe? Let’s dive into the important tips and strategies in our emergency stop guide.

Metal Lathe Emergency Stop Guide: Essential Safety Measures

Metal Lathe Emergency Stop Guide

Knowing how to quickly stop a metal lathe can save lives. This guide shares easy-to-follow tips for safely managing emergencies. You’ll learn where the emergency stop button is located and how to use it properly. Did you know that some lathes may have different locations for this crucial button? Understanding this can make all the difference in a moment of crisis. Stay safe and keep your workspace accident-free by following these simple steps.Types of Emergency Stop Mechanisms

Description of various emergency stop options (button, foot pedal, etc.).. Pros and cons of each type of mechanism..When it comes to stopping a metal lathe in a hurry, there are different options to choose from. You can use a stop button, which is easy to reach and simple to press. But watch out—if you hit it too hard, you might send it flying! Then there’s the foot pedal, perfect for hands-free stopping. Just remember, kicking is for football, not lathe stop buttons! Each mechanism has its pros and cons.

| Type | Pros | Cons |

|---|---|---|

| Stop Button | Easy to access | Can be accidentally pressed |

| Foot Pedal | Hands-free operation | Risk of tripping |

Choosing the right stop mechanism can save you from a sticky situation. Just like every superhero needs a reliable sidekick, your lathe needs the best emergency stop!

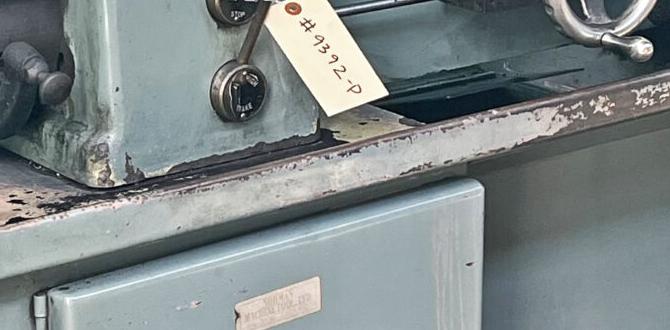

Identifying Emergency Stop Locations

Guidance on where emergency stop buttons should be placed on the machine.. Importance of visibility and accessibility in an emergency..Knowing where the emergency stop buttons are on a metal lathe is super important. You want them to be visible and easy to reach. Imagine trying to find one in a panic—yikes! They should be placed near the operator and not hidden behind any flashy buttons. This way, if something goes wrong, you can stop the machine faster than a cat jumping off a hot tin roof!

| Location Tips | Why It Matters |

|---|---|

| At eye level | Easy to spot during emergencies |

| Within arm’s reach | Quick access means fast response |

| Avoid cluttered areas | Less chance of a brain freeze |

Keep everyone safe and sound by ensuring these buttons are where you need them most! Safety never looked so good!

How to Properly Use the Emergency Stop

Stepbystep instructions on activating the emergency stop.. Discussion of best practices for quick and effective reactions..Imagine your metal lathe is running like a well-oiled machine, then suddenly, it takes a wild spin. Yikes! The emergency stop is your superhero here. To activate it, simply press the bright red button, usually right on the machine. Bam! It’s like hitting the brakes in a race car.

| Step | Action |

|---|---|

| 1 | Locate the emergency stop button. |

| 2 | Press the button firmly. |

| 3 | Assess the situation before restarting. |

For quick reactions, always know where this button lives. Think of it as a lifeguard on duty. If something goes haywire, don’t panic! Press quickly and breathe. Remember, safety isn’t just a rule; it’s your best buddy in the workshop.

Regular Maintenance of Emergency Stop Systems

Importance of regular checks and maintenance for reliability.. List of maintenance tasks and schedules for emergency stop systems..Regular checks on emergency stop systems are crucial for keeping machines safe and reliable. Think of it like checking your bike’s brakes before a race; you want those to work when it counts! Maintenance tasks should include inspecting buttons, testing functionality, and cleaning any dust. Here’s a handy table to guide your maintenance schedule:

| Task | Frequency |

|---|---|

| Inspect emergency stop buttons | Monthly |

| Test system functionality | Quarterly |

| Clean and remove debris | Monthly |

| Replace worn components | As needed |

By sticking to this plan, you’ll help ensure that your emergency stop system is always ready to kick into action. And remember, no one wants to play hide-and-seek with safety!

Training Operators on Emergency Procedures

Tips for developing a training program for lathe operators.. Strategies for conducting drills and assessments..Training operators is key for safe machine use. Start by developing a program that covers emergency stop procedures. Use clear steps and visuals to make learning easier. Regular drills help reinforce this training. Schedule a few drills each month to ensure operators stay prepared. Assess their skills often to spot areas needed for improvement. This boosts confidence and safety awareness.

What are some tips for a successful training program?

Focus on simplicity and hands-on practice. Use real-life scenarios to connect training with actual experiences. Encourage questions to make learning interactive.

Key training tips include:

- Clear instructions for all procedures.

- Frequent practice sessions.

- Feedback after drills for improvement.

Case Studies: Success and Failure of Emergency Stops

Analysis of realworld incidents involving metal lathes and emergency stops.. Lessons learned from both successful interventions and failures..Real-world stories about metal lathes show us both wins and misses with emergency stops. Some workers flipped the stop switch just in time to avoid injury. Other times, machines kept running, causing accidents. Here are key takeaways:

- Success Example: A quick stop saved a worker from harm.

- Failure Example: A failed emergency stop led to a serious accident.

These stories help us see how important it is to know how to use emergency stops correctly. Learning from both good and bad outcomes helps keep everyone safe.

What do metal lathe accidents teach us?

They show us the need for proper training and quick reactions. Understanding emergency stops can save lives. Proper training can make a big difference in safety.

Conclusion

In conclusion, knowing how to use the emergency stop on a metal lathe is crucial for safety. It helps prevent accidents and injuries. Always check the stop button before starting your work. Keep practicing and stay aware of your surroundings. For more information, consider reading guides on metal lathe safety. This way, you can work confidently and safely!FAQs

What Are The Key Features Of An Emergency Stop System For Metal Lathes?An emergency stop system for metal lathes has a few key features. First, it has a big red button that you can push quickly. This button makes the machine stop right away to keep you safe. Second, it has clear labels so you know where the button is. Finally, it should be easy to reach, no matter where you are standing.

How Do You Properly Implement An Emergency Stop Procedure When Operating A Metal Lathe?To stop a metal lathe in an emergency, first, keep calm. Look for the emergency stop button, usually a big red button. Press this button quickly if there’s a problem. If the machine doesn’t stop, you can unplug it from the wall. Always check to make sure everything is safe before starting again.

What Steps Should Be Taken To Ensure That The Emergency Stop Button On A Metal Lathe Is Easily Accessible And Functional?To keep the emergency stop button on a metal lathe easy to reach, you should place it in a spot you can quickly get to. Make sure you can see it clearly, so you know where it is. Regularly check that the button works and isn’t blocked by anything. Also, remind everyone using the lathe how to find and use the button safely.

What Safety Training Should Operators Receive Regarding The Emergency Stop Functions On Metal Lathes?You should learn where the emergency stop button is located on the metal lathe. Practice how to press it quickly if there’s an emergency. You also need to know when to use the emergency stop. We should always keep the area around the machine safe and clear. Regular drills can help us remember what to do.

How Can Operators Identify Potential Emergency Scenarios That Would Necessitate The Use Of The Emergency Stop On A Metal Lathe?To spot emergency situations on a metal lathe, you should look for signs of danger. If you hear strange sounds, see sparks, or notice unusual smoke, these could mean trouble. Always pay attention to any unusual movements or if the tool becomes stuck. If you feel worried or unsure, that’s a good time to use the emergency stop. It helps keep everyone safe!