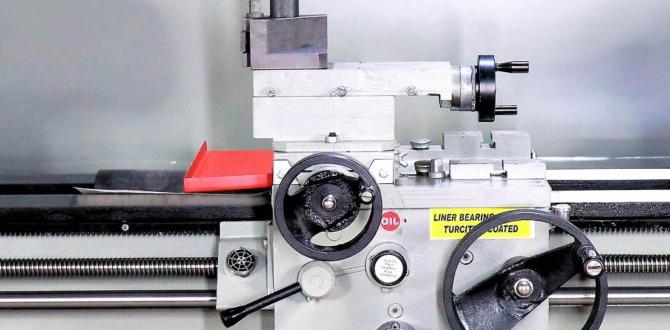

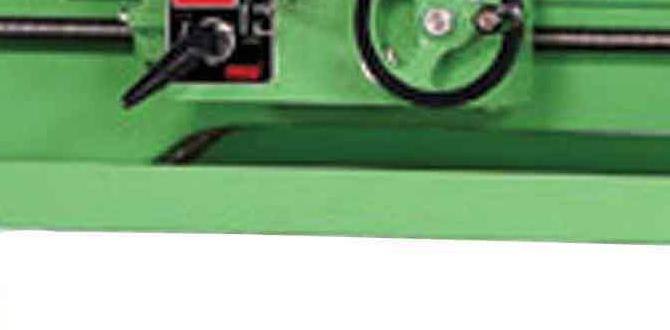

Imagine making a toy car. You spin a metal rod and shape it, just like magic. But, what makes this magic happen? Meet the metal lathe! It’s a special tool that turns metal into art.

But here’s a secret. Not everyone knows the best way to use it. Feed rates make a big difference. They decide how fast or slow the metal moves. This is where a metal lathe feed rates chart helps.

Why should you care? Well, using the right feed rate saves time. It stops mistakes too. It’s like finding the right speed on a bike. If you go too fast, you might fall; too slow, and it gets boring.

Did you know feed rates can change what you make? Yes! Just like a cook uses recipes, machinists use this chart. It tells them the secret for a perfect piece. Fascinating, isn’t it?

Understanding The Metal Lathe Feed Rates Chart When It Comes To Operating A Metal Lathe Efficiently, The Feed Rates Chart Is An Indispensable Tool For Machinists. Proper Understanding And Utilization Of This Chart Can Enhance The Precision And Quality Of Work While Also Extending The Life Of Your Cutting Tools. Here, We Explore The Nuances Of The Metal Lathe Feed Rates Chart, Including Its Components And Significance In Machining Processes. **Components Of The Metal Lathe Feed Rates Chart:** A Metal Lathe Feed Rates Chart Typically Includes Critical Information Such As The Speed Of The Machine, The Type Of Material Being Machined, And The Feed Rate For Different Operations. It Is Crucial For Selecting The Appropriate Settings For Your Lathe Operations. 1. **Speed (Rpm):** This Refers To The Rotational Speed Of The Lathe Spindle, Often Measured In Revolutions Per Minute (Rpm). High-Speed Settings Are Usually Employed For Softer Materials, Whereas Harder Materials Require A Lower Speed. 2. **Material Type:** Different Materials Require Different Feed Rates. For Example, Aluminum Might Need A Higher Feed Rate Compared To Stainless Steel. 3. **Feed Rate (Ipr Or Fpr):** The Feed Rate Is A Measure Of How Fast The Cutting Tool Is Advanced Along The Workpiece, Usually Given In Inches Per Revolution (Ipr) Or Feed Per Revolution (Fpr). Proper Adjustment Of Feed Rate Is Crucial For Maintaining Tool Sharpness And Achieving A Superior Finish. **Significance Of The Feed Rates Chart:** The Precise Selection Of Feed Rates Affects Multiple Aspects Of The Machining Process: – **Surface Finish:** Incorrect Feed Rates Can Lead To Poor Surface Finish Or Even Tool Marks On Your Workpiece. – **Tool Life:** Using The Right Feed Rate Can Prolong Tool Life By Minimizing Excess Wear Or Overheating. – **Efficiency:** High Feed Rates Can Speed Up Production, But Inappropriately High Rates Risk Damaging The Tool Or Workpiece. **Tips For Using The Feed Rates Chart Efficiently:** – **Material Specific Settings:** Always Select Feed Rates That Are Specific To The Material You Are Working With To Avoid Operational Issues. – **Monitor Tool Performance:** Continuously Monitor The Tool’S Performance To Ensure That The Selected Feed Rate Is Providing The Expected Results. – **Adjust For Wear:** As Tools Wear, Adjustments To Feed Rates May Be Necessary To Maintain Quality And Efficiency. Understanding And Utilizing The Metal Lathe Feed Rates Chart Is Essential For Any Machinist Aiming To Improve Operational Efficiency And Product Quality In The Workshop. Familiarity With Its Components And Proper Application Can Be The Difference Between A Successful Project And A Compromised One.

Understanding Metal Lathe Feed Rates Chart

Imagine making a magic wand from a metal rod. You need the right speed for the tool to shape it smoothly. That’s what a metal lathe feed rates chart helps with! This chart tells you how fast the tool should move across the metal. It ensures precise cuts every time. Did you know the wrong speed can break the tool? Learning how to read this chart saves time and prevents mistakes.Components of a Metal Lathe Feed Rates Chart

Explanation of speed and feed tables. Details on units of measurement and significance. How to read and interpret a feed rates chart.Understanding how speed and feed tables work is like unlocking the secrets of a metal lathe. Picture it as a magical treasure map that guides you to the perfect cut! These tables list important details about how fast and deep the tool should move. The units, often RPM and inches per minute, hint at the chart’s importance—it’s like the GPS for machining.

To read a feed rates chart, think of it as a fun puzzle. Check the speed, then match it with the feed—easy-peasy! Here’s a basic example:

| Material | Speed (RPM) | Feed (IPM) |

|---|---|---|

| Aluminum | 3000 | 0.007 |

| Steel | 2000 | 0.005 |

So next time you see these charts, remember: they’re your helpful pals in choosing the right settings for your lathe work. By following these guidelines, you keep your lathe happy and your projects shiny!

Variables Affecting Feed Rates

Material type: steel, aluminum, and more. Tool type and condition. Machine capabilities and limitations.Feed rates in a metal lathe can change based on many factors. Different materials, like steel and aluminum, need different speeds. Steel often requires slower speeds than aluminum because it’s harder. The tool’s type and condition also matter. A sharp, clean tool works better than a dull one. Machine capabilities can limit feed rates too. Older machines might not handle fast speeds. Always check your machine’s manual for the best settings for safety and accuracy.

Why does steel need a slower feed rate than aluminum?

Steel is tougher to cut. It is denser and harder than aluminum, which means cutting it takes more effort. A slower feed rate prevents tool wear and overheating.Key Points

- Steel: Harder, needs slow speed.

- Aluminum: Softer, allows faster speed.

Using the right speed for each material helps achieve precise results and keeps the tools in good shape.

Benefits of Using Accurate Feed Rates

Enhancing machining efficiency. Achieving superior surface finish quality. Improving tool lifespan and reducing wear.Having the right feed rates in machining is like finding the perfect pair of shoes – everything fits just right! This means making your work processes smoother and faster. It helps machines cut better, giving metal pieces a shiny, smooth finish. Plus, using the right rates helps cutting tools last longer, like your favorite pen that never runs out of ink. Imagine a world where machines hum happily and spare you the headache of constant tool changes!

| Benefits | Impact |

|---|---|

| Efficiency | Faster and smoother processes |

| Surface Finish | Smoother, shinier results |

| Tool Lifespan | Longer-lasting tools |

To ensure the best results, use a metal lathe feed rates chart as your trusty guide. It helps you keep everything in line, much like a chore chart keeps chores, well, less of a chore. Engineers often say, “Proper feed rates prevent headaches and save money.” So, if you want to be the superhero of your workshop, keep those charts handy!

Step-by-Step Guide to Calculating the Ideal Feed Rate

Methodology for manual calculation. Utilizing software and digital tools. Tips for adjusting feed rates based on trial and error.Calculating the perfect feed rate for your metal lathe can be tricky but doable. First, learn to calculate manually. You need to consider factors like tool type and material hardness. A pen, paper, and calculator will be your best pals here. Luckily, many modern tools have digital software that does this heavy lifting for you. Handy, right? However, sometimes it’s all about trial and error. You might need to adjust tastes like a chef trying a new recipe! So, give it a go and see what works best.

| Tool Type | Material Hardness | Suggested Feed Rate |

|---|---|---|

| High-Speed Steel | Soft | 0.1 – 0.2 mm/rev |

| Carbide | Hard | 0.15 – 0.3 mm/rev |

Did you know? Trial and error is often how scientists like Einstein made big discoveries! So, don’t fret about trying different feed rates. With time, you’ll find the “Goldilocks” rate – not too slow, not too fast, but just right!

Common Mistakes and How to Avoid Them

Misinterpretation of chart data. Overlooking material and tool compatibility. Ignoring machine specifications.Interpreting feed rate charts can be tricky. A common error is reading the chart wrong, which can lead to lots of confusion. Always double-check the data! Another pitfall is not considering if the tool and material are friends or foes. To avoid damage or poor results, ensure they work well together. Lastly, don’t let your lathe feel ignored. Machines have unique traits; know them well. Here’s a handy reminder:

| Item | Consideration |

|---|---|

| Chart Data | Double-check accuracy |

| Material & Tool | Check compatibility |

| Machine Specs | Understand capabilities |

Machines aren’t mind-readers; they need the right data to work well. It’s like baking a cake: mess up the flour with the sugar, and you’ll have a sweet disaster! So, keep an eye on these tips to keep the lathe happy and productive.

Expert Recommendations for Beginners

Starting points for common materials. Safe practices for experimenting with feed rates. Resources for further learning and practice.Starting with a metal lathe can be like trying to ride a unicycle for the first time—it might wobble a bit. Experts suggest beginning with common materials like aluminum and mild steel, which are more forgiving. A little practice makes it less of a circus act. Remember, safety first! Keep your fingers away from the spinning parts, or you might end up waving hello in a new way. Need more guidance? Plenty of resources await, from friendly YouTube channels to handy books.

| Material | Starting Feed Rate |

|---|---|

| Aluminum | 0.002-0.004 inches per revolution |

| Mild Steel | 0.001-0.003 inches per revolution |

Frequently Asked Questions about Metal Lathe Feed Rates

Addressing common user queries. Debunking myths and misunderstandings.Are you curious about metal lathe feed rates? Many are! It’s essential for accurate machining. People often ask about feed rate settings. Here’s a quick guide.

What is a metal lathe feed rate?

The feed rate is how fast the tool moves across the metal. It’s like how fast you color with a crayon. Go slow, and you get neat lines!

Why is feed rate important?

A good feed rate means smoother cuts. It helps your machine work right and keeps metal from getting damaged.

What are common myths?

Some think faster is better. That’s not true. Fast can mean mistakes. Another myth: all metals need the same feed rate. But each metal is different!

- Aluminum? Go faster.

- Steel? Move slower.

Be careful! Check a metal lathe feed rates chart to pick the right speed. Remember, it’s like baking. Follow the recipe for best results!

Resources and Tools for Optimizing Feed Rates

Recommended charts and databases. Software tools and apps for machining calculations.Optimizing Feed Rates Knows No Bounds

Boost your machining skills with smart tools and resources! Charts and databases show ideal feed rates for different metals. They help with picking the best speed. Software tools help with calculations, too. You can find many machining apps and programs. They keep the process smooth and easy.

- Machinist’s Handbook: This book is a great help. It has a wealth of charts and guides.

- Online Databases: Many websites have free feed rate info.

- Machining Software: Apps like Mach3 and Fusion 360 are useful for axle feed rate calculations.

Why are software tools important?

Software tools help in calculating feed rates fast. They show clear numbers. You can make changes easily based on them. This saves time and cut errors. Faster work means more output and less waste.

Using these resources grows skills. This leads to better results and more successful projects. As quoted, “With the right tools, any job gets half done.”

Conclusion

Understanding a metal lathe feed rates chart is important. It helps us choose the right speed for cutting materials safely and accurately. By following the chart, we can prevent damage and improve our work. To learn more, let’s explore tutorials or guides on using these charts effectively. Keep practicing for better skills!FAQs

How Do I Determine The Appropriate Feed Rate For Different Materials When Using A Metal Lathe?To find the right feed rate for a metal lathe, you need to know what type of material you’re using. Different materials need different speeds. We can look at a chart that shows the best feed rates for each material. Always start slow and watch how the metal shapes. You can adjust the speed if needed to make it work better.

What Are The Consequences Of Using An Incorrect Feed Rate On A Metal Lathe?If you use the wrong feed rate on a metal lathe, it can cause problems. The metal might look rough or uneven. The tool could wear out faster and break easily. This might also make the machine shake or stop working right. Always check the feed rate to keep things safe and smooth.

How Does The Feed Rate Affect The Surface Finish And Tolerances Of A Workpiece On A Metal Lathe?The feed rate is how fast we move the cutting tool across the metal. If you move it slowly, the surface of the metal will be smooth and shiny. However, if you move it too quickly, the surface can become rough and bumpy. Slower speeds also help the metal stay the right size and shape (these are called tolerances). So, controlling the feed rate helps the metal look nice and fit together well with other pieces.

Are There Standard Charts Or Guidelines For Feed Rates When Turning Various Metals On A Lathe?Yes, there are charts to help us! When you use a lathe, different metals need different speeds for cutting. These charts tell us the best feed rates, which is how fast the tool moves. They help make smooth pieces without breaking the tools. It’s like having a helpful guide when you make cool things!

How Can I Adjust The Feed Rate During A Lathe Operation To Optimize Both Productivity And Tool Wear?You can change the speed of the machine to make it work better and protect the tool. If you make the machine go too fast, the tool might break quicker. If it’s too slow, the work takes too long. Try using a medium speed so the tool lasts longer and you get the job done faster. Practice and watch closely to find the best speed.