Setting up a toolroom can be an exciting project. Have you ever wondered how professionals create precise parts? One key tool in their setup is the metal lathe. This machine is a game-changer for anyone serious about machining.

Imagine shaping metal with ease. A metal lathe helps you turn raw materials into functional pieces. It gives you the power to make custom tools and parts. Did you know that a well-set-up lathe can make your work faster and more accurate? With the right features, it becomes a vital part of your toolroom.

Whether you are a beginner or an expert, understanding how to use a metal lathe is essential. This article will guide you through what to consider for your setup. You’ll discover tips that can help you choose the best lathe for your needs.

So, are you ready to take your toolroom to the next level? Let’s dive in and explore the world of metal lathes!

Metal Lathe For Toolroom Setup: A Comprehensive Guide

Metal Lathe for Toolroom Setup

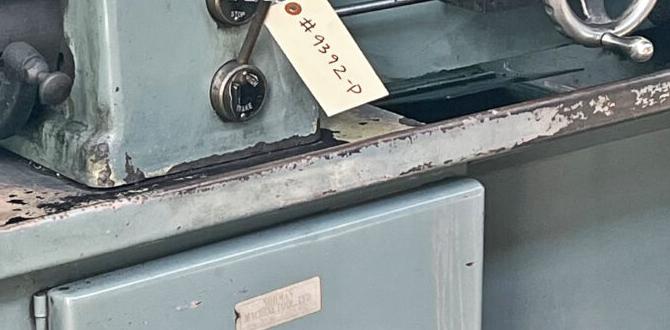

Setting up a metal lathe in your toolroom can transform your workshop. Have you ever tried shaping metal into precise forms? A metal lathe allows you to do just that! It spins the metal, while cutting tools shape it. This setup lets you make everything from small parts to larger items easily. Plus, did you know that metal lathes have been used for centuries? They remain a crucial tool for both hobbyists and professionals today!Understanding Metal Lathes

Definition and purpose of a metal lathe. Types of metal lathes commonly used in toolrooms.A metal lathe is a machine that shapes metal. It spins the metal while a tool cuts it into different shapes. Imagine a magician, making metal disappear into beautiful forms! There are several types of metal lathes used in toolrooms. Engine lathes are common for general work, while CNC lathes use computers for precision. Each type has its charm, just like superheroes of the metal world!

| Type of Metal Lathe | Purpose |

|---|---|

| Engine Lathe | General machining work |

| CNC Lathe | Highly precise and automated tasks |

| Turret Lathe | For repetitive work in sets |

Key Features to Consider in a Metal Lathe

Spindle speed and power. Size and capacity requirements. Accuracy and precision features.Choosing the right metal lathe can make a big difference in your projects. One key feature is spindle speed and power. A higher speed often allows you to work with a variety of materials effectively. The lathe’s size and capacity should match your workspace and project needs. Finally, look for accuracy and precision features. These ensure your cuts are clean and exact, making your work look great.

What are the essential features to look for in a metal lathe?

Consider these points:

- Spindle Speed: Choose a lathe with adjustable speeds for versatile usage.

- Power: Ensure enough horsepower for your tasks.

- Size: Match the lathe to your workspace constraints.

- Precision: Check for digital readouts for accuracy.

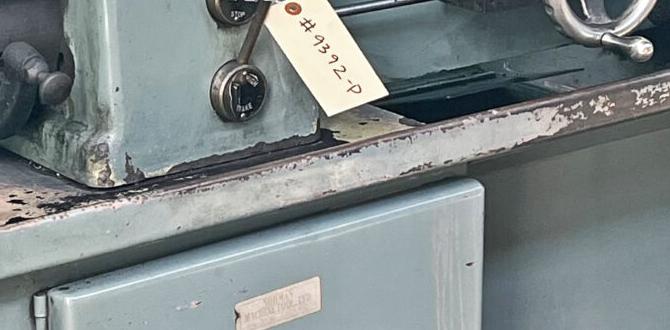

Choosing the Right Metal Lathe for Your Toolroom

Assessing your specific needs and applications. Comparing reputable brands and models.Picking the right metal lathe for your toolroom starts with knowing your needs. Ask yourself what projects you’ll work on. Do you need a small one for simple tasks or a bigger one for complex jobs? Next, check out some popular brands. Compare features and reviews to find the best fit. Some key points to consider include:

- Size and space in your toolroom

- Types of materials you will work with

- Budget and warranty options

Making a smart choice will help you get the most out of your projects!

What should I consider when choosing a metal lathe?

Consider your style of work and specific tasks. Look for features that match your projects to get the best results.

Essential Accessories for Metal Lathe Operations

Tooling options: cutters, chucks, and collets. Measurement tools: calipers, micrometers, and gauges.When working with a metal lathe, having the right accessories is key. You need tools that make your job easier. Here are some important options:

- Cutters: These shape and cut materials.

- Chucks: They hold the workpiece securely.

- Collets: These grip tools tightly for precise work.

Measuring accurately is just as crucial. Use these tools:

- Calipers: Great for measuring width and depth.

- Micrometers: Perfect for very small measurements.

- Gauges: Useful for checking sizes or fittings.

With the right tooling and measuring instruments, you can achieve better results and make your projects easier. So, gear up and start working!

What are essential accessories for metal lathe operations?

The essential accessories include cutters, chucks, collets, calipers, micrometers, and gauges. These tools improve precision and efficiency in your lathe work.

Safety Practices When Using Metal Lathes

Personal protective equipment (PPE) requirements. Proper machine operation protocols.Working with metal lathes can be fun but also dangerous. To stay safe, wear the right personal protective equipment (PPE). Always use safety glasses and ear protection. A dust mask can keep your lungs safe from particles.

Follow proper machine operation steps. Keep your hands away from moving parts. Make sure your work area is clean and tidy. Always check the machine before use. These steps help prevent accidents and keep everyone safe.

What is essential PPE for metal lathe use?

Essential PPE includes safety glasses, ear protection, and gloves. Wearing these items helps protect you from flying debris and loud noises.

Important Operating Practices:

- Keep tools organized.

- Use both hands when operating the machine.

- Never rush your work.

- Report any problems immediately.

Maintenance Tips for Longevity of Metal Lathes

Routine cleaning and lubrication. Troubleshooting common issues.Keeping a metal lathe clean and well-lubricated is key for its long life. Regularly wipe down the lathe to remove dust and metal shavings. Apply lubricant to moving parts to ensure they work smoothly. This helps prevent wear and tear.

If you run into problems, here are some quick tips:

- Check for loose parts and tighten them.

- Inspect the belts for wear and tear.

- Make sure the motor isn’t overheating.

Taking these simple steps can keep your metal lathe running like new!

How can I troubleshoot my metal lathe?

Common issues can often be solved by checking for loose parts or worn-out belts. Listen for strange noises or changes in performance.

Setting Up Your Metal Lathe in the Toolroom

Ideal workspace configuration. Fixture and mounting considerations.Finding the right spot for your metal lathe matters. You need enough space to work safely. The ideal workspace is well-lit and clean. It should allow you to move around comfortably. Think about fixtures and mounts, too. They help hold materials in place. Strong and stable mounts save you time. Use clamps or vises to secure parts while working.

What is important for setting up a metal lathe?

Having a clear and safe workspace is crucial. Also, secure fixtures ensure your tools work well.Key Points:

- Clear space with good lighting

- Stable mounts and clamps

- Easy access to tools

Learning Resources and Training for Metal Lathe Use

Recommended books, manuals, and tutorials. Online courses and local workshops available for training.Many resources exist to learn about using a metal lathe. Books and manuals provide clear instructions and tips. You can find online tutorials that offer visual guidance. Local workshops give hands-on practice and professional help.

- Books: *“Lathe Work: A Complete Guide”*

- Online Courses: Sites like Coursera or Udemy offer metal lathe courses.

- Workshops: Check your local community colleges for classes.

What are the best resources for metal lathe training?

Books, online courses, and hands-on workshops are some of the best resources for learning about metal lathes. You’ll find information that fits your learning style.

Conclusion

In summary, a metal lathe is essential for any toolroom setup. It helps you create precise parts and improves your skills. You should consider size, features, and budget when choosing one. By understanding these basics, you’ll make a smart choice. Dive deeper into metalworking books or online guides to enhance your knowledge and gain confidence in your projects!FAQs

Sure! Here Are Five Related Questions On The Topic Of Metal Lathes For Toolroom Setups:Sure! A metal lathe is a machine that helps shape metal into different parts. It spins the metal while a tool cuts it into the right shape. In a toolroom, we use lathes to make precise tools and parts. They are important for building things like cars and machines. Using a lathe takes practice, but it can be fun and rewarding!

Sure! Please provide the question you’d like me to answer.

What Are The Key Features To Look For When Selecting A Metal Lathe For A Toolroom Environment?When choosing a metal lathe for a toolroom, look for size and weight. It should fit your space and feel sturdy. Check for good speed control so you can adjust how fast it spins. Look for easy-to-use controls and clear markings. Lastly, make sure it has safety features to keep you safe while working.

How Does The Size And Capacity Of A Metal Lathe Impact Its Suitability For Various Machining Tasks In A Toolroom?The size and capacity of a metal lathe help us decide what we can make with it. A bigger lathe can handle larger pieces of metal. This means you can create bigger parts for machines or other projects. If you only have a small lathe, you may need to make smaller items. So, the right size helps you do your job better and faster!

What Types Of Materials Can Be Effectively Machined Using A Metal Lathe In A Toolroom Setup?You can use a metal lathe to shape many materials. It works well with soft metals like aluminum and brass. You can also machine harder metals like steel. Wood and plastic can be shaped on some lathes too. Remember, each material needs special care while you work.

What Are The Most Common Accessories And Tooling Required To Optimize A Metal Lathe’S Performance In A Toolroom?To make a metal lathe work better, we need some tools and accessories. First, you should have cutting tools like drills and different blades. Next, a tool holder keeps these cutting tools in place. We also need a good measuring tool, like calipers, to check sizes. Finally, a chuck is important for holding the metal while we work on it. These tools help us do a great job!

How Do Maintenance Practices Differ Between Manual And Cnc Metal Lathes In A Toolroom Setting?Manual lathes need regular cleaning and oiling to keep them running smoothly. You often check the belts and gears for wear. For CNC lathes, which are computer-controlled, you focus on software updates and electronics. We also make sure the cutting tools are sharp and the machine is calibrated. Both types need care, but their needs are a bit different.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Metal Lathes For Toolroom Setups:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! A metal lathe is a machine that helps shape metal into different parts. It spins the metal while a tool cuts it into the right shape. In a toolroom, we use lathes to make precise tools and parts. They are important for building things like cars and machines. Using a lathe takes practice, but it can be fun and rewarding!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Key Features To Look For When Selecting A Metal Lathe For A Toolroom Environment?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When choosing a metal lathe for a toolroom, look for size and weight. It should fit your space and feel sturdy. Check for good speed control so you can adjust how fast it spins. Look for easy-to-use controls and clear markings. Lastly, make sure it has safety features to keep you safe while working.”}},{“@type”: “Question”,”name”: “How Does The Size And Capacity Of A Metal Lathe Impact Its Suitability For Various Machining Tasks In A Toolroom?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The size and capacity of a metal lathe help us decide what we can make with it. A bigger lathe can handle larger pieces of metal. This means you can create bigger parts for machines or other projects. If you only have a small lathe, you may need to make smaller items. So, the right size helps you do your job better and faster!”}},{“@type”: “Question”,”name”: “What Types Of Materials Can Be Effectively Machined Using A Metal Lathe In A Toolroom Setup?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can use a metal lathe to shape many materials. It works well with soft metals like aluminum and brass. You can also machine harder metals like steel. Wood and plastic can be shaped on some lathes too. Remember, each material needs special care while you work.”}},{“@type”: “Question”,”name”: “What Are The Most Common Accessories And Tooling Required To Optimize A Metal Lathe’S Performance In A Toolroom?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To make a metal lathe work better, we need some tools and accessories. First, you should have cutting tools like drills and different blades. Next, a tool holder keeps these cutting tools in place. We also need a good measuring tool, like calipers, to check sizes. Finally, a chuck is important for holding the metal while we work on it. These tools help us do a great job!”}},{“@type”: “Question”,”name”: “How Do Maintenance Practices Differ Between Manual And Cnc Metal Lathes In A Toolroom Setting?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Manual lathes need regular cleaning and oiling to keep them running smoothly. You often check the belts and gears for wear. For CNC lathes, which are computer-controlled, you focus on software updates and electronics. We also make sure the cutting tools are sharp and the machine is calibrated. Both types need care, but their needs are a bit different.”}}]}