Have you ever wondered how a metal lathe works? These machines shape metal into smooth, precise parts. But what happens when the headstock breaks down? It can feel overwhelming to fix it, right? Don’t worry! A metal lathe headstock rebuild guide can help you.

Rebuilding a headstock isn’t just for experts. Many hobbyists have tackled this task and succeeded! Just imagine bringing your old lathe back to life. With a little patience and the right guidance, it’s possible.

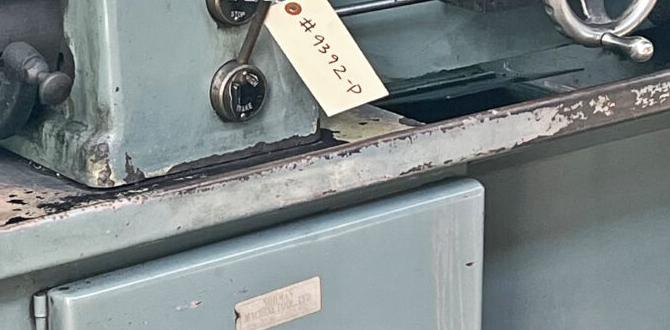

Did you know that many lathes are older than you? Some have been used for decades! When these machines start to fail, they still have lots of potential. A careful rebuild can save them. In this guide, we will explore how to rejuvenate your lathe’s headstock with simple steps.

Get ready to dive into the world of metal lathes. You’ll learn important tips and tricks to help make your project a success. Who knows? You might just become a lathe rebuilding expert!

Metal Lathe Headstock Rebuild Guide: Essential Tips & Techniques

Metal Lathe Headstock Rebuild Guide

Rebuilding a metal lathe headstock can seem tricky, but it’s rewarding. You can extend your lathe’s life with careful steps. First, gather the right tools and parts. Then, take apart the headstock slowly; note where each piece goes. A fun fact: many lathes have hidden wear that can be fixed easily! Once rebuilt, your lathe will run smoothly, allowing you to create amazing projects. Are you ready to give your lathe a fresh start?Understanding the Headstock Functionality

Explanation of the headstock’s role in a metal lathe system. Importance of maintaining the headstock for optimal performance.The headstock is a key part of any metal lathe. It holds the motor and controls the spindle. The spindle spins the workpiece, allowing it to be shaped or cut. If the headstock is not well-maintained, it can cause issues. This can lead to poor precision and quality in the work. Regular checks and repairs keep everything running smoothly.

- Ensures accuracy: A well-functioning headstock helps make precise cuts.

- Increases lifespan: Regular maintenance can extend the headstock’s life.

- Enhances performance: A balanced headstock improves overall lathe efficiency.

Why is headstock maintenance important?

Maintaining the headstock is essential for precision. It ensures smooth operation and helps prevent costly repairs.

Tools and Materials Needed for Rebuilding

List of essential tools required for the rebuild process. Recommended replacement parts and materials necessary for the rebuild.To rebuild a metal lathe headstock, you’ll need some important tools and parts. First, gather these tools:

- Socket set

- Wrenches

- Screwdrivers

- Caliper

- File

- Measuring tape

Next, consider these replacement parts and materials:

- Bearings

- Spindle

- Gears

- Lubricants

- Seals

Having the right tools and materials makes the process smoother and safer. It’s like having a treasure map; you won’t get lost!

What tools do you need for rebuilding a metal lathe headstock?

You need simple tools like wrenches, screwdrivers, and a caliper. These help you take apart and put the lathe back together easily.

Preparing for the Rebuild

Steps to safely disassemble the headstock. Tips for documenting and organizing parts during disassembly.Before you start the headstock rebuild, follow these simple steps to disassemble it safely. First, unplug the machine. Next, remove the screws carefully. Keep parts organized by using small containers. Label each part to avoid confusion later. You can also take pictures during disassembly to help you remember where everything goes.

- Unplug the machine.

- Wear safety goggles.

- Use labeled bags for small parts.

- Document with photos.

What tools do I need for a headstock rebuild?

You need basic tools: a screwdriver, wrench, pliers, and a clean workspace. These tools make the rebuild easier and safer.

Inspecting Components for Wear and Damage

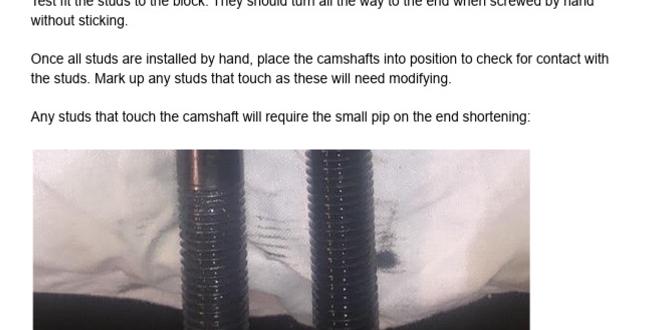

Key components to evaluate for signs of wear. Techniques for assessing the condition of bearings, gears, and spindles.Look closely at your lathe’s key parts to spot wear and tear. Check the bearings, gears, and spindles for any funny sounds or causes of concern. For instance, if the spindle wobbles, your lathe might be dancing instead of working! Use your fingers to feel for rough spots and listen for strange noises. Here’s a quick guide:

| Component | Signs of Wear | Assessment Technique |

|---|---|---|

| Bearings | Roughness, play | Spin and listen |

| Gears | Missing teeth | Visual inspection |

| Spindles | Wobbling | Balance test |

Keep your eye on these parts to avoid clubhouse chaos later!

Cleaning and Restoring Components

Best practices for cleaning different materials found within the headstock. Methods for restoring worn components or deciding when to replace them.Keeping the headstock clean is key to a smooth rebuild. Start with alcohol or a gentle soap solution for aluminum and plastic parts. Use a soft brush to reach tight spots. For steel, a wire brush can help, but be careful not to scratch the surface. If parts are worn out, assess if they can be restored or should be replaced. Sometimes, a simple polish works miracles, while in other cases, a replacement might be cheaper than a pricey repair. Remember, “A clean lathe is a happy lathe!”

| Material | Cleaning Method | Restoration Option |

|---|---|---|

| Aluminum | Alcohol or mild soap | Polish or replace |

| Plastic | Gentle soap solution | Repair or replace |

| Steel | Wire brush | Polish or replace |

Reassembly Process Explained

Stepbystep guide to reassembling the headstock correctly. Common pitfalls to avoid during the reassembly phase.To reassemble the headstock, follow these simple steps:

- First, align all parts carefully.

- Next, secure the bearings tightly.

- Then, attach the spindle with smooth motion.

- Lastly, check for any wobbling or noise.

Be aware of common mistakes:

- Don’t rush; take your time.

- Make sure to use the correct tools.

- Double-check every part fits well.

These tips will help you avoid problems and ensure a successful rebuild! Happy lathing!

What is the first step in the reassembly process?

The first step is to align all parts carefully to ensure a proper fit.

How can I avoid common pitfalls during reassembly?

To avoid mistakes, take your time, use the right tools, and double-check each part.

Calibrating the Headstock After Rebuild

Importance of calibration for accuracy in machining. Procedures for aligning and calibrating the headstock after rebuild.Calibration is key for precise machining. It ensures tools cut exactly as needed. After rebuilding the headstock, follow these steps for alignment:

- Check all parts for tightness.

- Use a level to align the headstock.

- Adjust the spindle using a dial indicator.

- Verify that the tailstock is aligned with the headstock.

Taking time to calibrate will improve your results. A well-calibrated machine runs smoother and lasts longer.

Why is calibration important?

Calibration is important for accuracy. Small errors can lead to big problems during machining. A tiny misalignment can ruin your work.

Maintenance Tips for Longevity

Regular maintenance practices to extend the life of the headstock. Recommended lubrication and inspection schedules.Taking care of your lathe headstock is like watering a plant: a little love goes a long way! Regularly check for wear and tear, and don’t forget to clean out any dust bunnies. Schedule oil checks every month to keep everything running smoothly. You wouldn’t want your machine to sound like a cat trying to purr with a hairball, right? Here’s a handy chart to help you with your maintenance schedule:

| Maintenance Task | Frequency |

|---|---|

| Inspect for wear | Monthly |

| Lubrication | Every 3 months |

| Deep Clean | Every 6 months |

Remember, taking care of your tools means they’ll take care of you! Happy lathe-ing!

Troubleshooting Common Issues

Guide to identifying and fixing common problems postrebuild. Tips for troubleshooting unusual noises or performance issues.After a rebuild, your metal lathe might act a bit quirky. Strange noises or weird vibrations can pop up. Don’t panic! Most issues are just like a cat caught in a tree. They can be figured out!

Start by checking the belt tension. If it’s too loose or tight, it can make a racket! Next, look at the bearings. Worn bearings can sound like a squeaky toy. If you hear something unusual, it’s time to investigate!

| Issue | Possible Cause | Solution |

|---|---|---|

| Noisy Operation | Loose belt or worn bearings | Tighten belt or replace bearings |

| Inconsistent Cutting | Dirty tools or loose setup | Clean tools and tighten all fixtures |

Stay calm, check the basics, and your lathe will purr like a kitten again!

Conclusion

In conclusion, a metal lathe headstock rebuild guide helps you understand important steps for maintenance. You learn about tools, parts, and techniques. This rebuild can improve your lathe’s performance and lifespan. Don’t hesitate to dive deeper into repair resources or tutorials. Start your journey today and enhance your metalworking skills!FAQs

Sure! Here Are Five Related Questions On The Topic Of Metal Lathe Headstock Rebuild:Sure! Here are five questions about rebuilding a metal lathe headstock: 1. What tools do you need for the rebuild? You need basic tools like wrenches, screwdrivers, and possibly some oil. 2. How do you take it apart? You carefully remove the screws and parts, remembering where everything goes. 3. What should you check for damage? Look for cracks or worn-out parts that need to be fixed or replaced. 4. How do you put it back together? Reverse the steps you took to take it apart, ensuring everything fits snugly. 5. How do you test it after rebuilding? Turn it on and watch for smooth movement. Make sure everything works properly.

Sure! Please ask your question, and I’ll be happy to help you with a short answer.

What Are The Common Signs That Indicate A Headstock Rebuild Is Necessary For A Metal Lathe?You might need to rebuild the headstock of your metal lathe if you hear loud noises while it runs. If you notice that the machine shakes or wobbles, that’s another sign. Also, look for changes in how smoothly the lathe turns. If the lathe doesn’t hold its speed or has trouble moving, a rebuild could help fix it.

What Tools And Materials Are Required For A Successful Metal Lathe Headstock Rebuild?For a successful metal lathe headstock rebuild, you need some basic tools and materials. First, gather wrenches and screwdrivers to take everything apart. You will also need a clean cloth to wipe away dirt. Some grease or oil will help everything move smoothly again. Don’t forget new bearings if the old ones are worn out!

How Do I Properly Disassemble A Metal Lathe Headstock Without Damaging Any Components?To disassemble a metal lathe headstock, start by unplugging the lathe for safety. Next, carefully remove any screws and bolts holding the headstock in place. Use a soft cloth to protect the parts while you work. Take pictures as you go, so you remember how to put everything back together. Finally, keep all the small parts organized in a container.

What Are The Key Steps In Aligning And Calibrating The Headstock After A Rebuild?To align and calibrate the headstock after a rebuild, follow these steps. First, make sure the headstock is level. Next, check if the spindle spins straight by using a tool called a dial gauge. Then, adjust the headstock until it is perfectly aligned. Lastly, tighten all the screws and double-check everything to make sure it’s right.

How Can I Prevent Future Issues With The Headstock After Completing The Rebuild Process?To keep the headstock safe after rebuilding, you can follow a few simple steps. First, check the parts regularly to make sure they are tight. Next, keep it clean and free from dust. Also, always handle it gently and avoid dropping it. Finally, store it in a safe place when not in use. These steps will help it last longer!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Metal Lathe Headstock Rebuild:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are five questions about rebuilding a metal lathe headstock: 1. What tools do you need for the rebuild? You need basic tools like wrenches, screwdrivers, and possibly some oil. 2. How do you take it apart? You carefully remove the screws and parts, remembering where everything goes. 3. What should you check for damage? Look for cracks or worn-out parts that need to be fixed or replaced. 4. How do you put it back together? Reverse the steps you took to take it apart, ensuring everything fits snugly. 5. How do you test it after rebuilding? Turn it on and watch for smooth movement. Make sure everything works properly.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please ask your question, and I’ll be happy to help you with a short answer.”}},{“@type”: “Question”,”name”: “What Are The Common Signs That Indicate A Headstock Rebuild Is Necessary For A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You might need to rebuild the headstock of your metal lathe if you hear loud noises while it runs. If you notice that the machine shakes or wobbles, that’s another sign. Also, look for changes in how smoothly the lathe turns. If the lathe doesn’t hold its speed or has trouble moving, a rebuild could help fix it.”}},{“@type”: “Question”,”name”: “What Tools And Materials Are Required For A Successful Metal Lathe Headstock Rebuild?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “For a successful metal lathe headstock rebuild, you need some basic tools and materials. First, gather wrenches and screwdrivers to take everything apart. You will also need a clean cloth to wipe away dirt. Some grease or oil will help everything move smoothly again. Don’t forget new bearings if the old ones are worn out!”}},{“@type”: “Question”,”name”: “How Do I Properly Disassemble A Metal Lathe Headstock Without Damaging Any Components?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To disassemble a metal lathe headstock, start by unplugging the lathe for safety. Next, carefully remove any screws and bolts holding the headstock in place. Use a soft cloth to protect the parts while you work. Take pictures as you go, so you remember how to put everything back together. Finally, keep all the small parts organized in a container.”}},{“@type”: “Question”,”name”: “What Are The Key Steps In Aligning And Calibrating The Headstock After A Rebuild?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To align and calibrate the headstock after a rebuild, follow these steps. First, make sure the headstock is level. Next, check if the spindle spins straight by using a tool called a dial gauge. Then, adjust the headstock until it is perfectly aligned. Lastly, tighten all the screws and double-check everything to make sure it’s right.”}},{“@type”: “Question”,”name”: “How Can I Prevent Future Issues With The Headstock After Completing The Rebuild Process?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep the headstock safe after rebuilding, you can follow a few simple steps. First, check the parts regularly to make sure they are tight. Next, keep it clean and free from dust. Also, always handle it gently and avoid dropping it. Finally, store it in a safe place when not in use. These steps will help it last longer!”}}]}