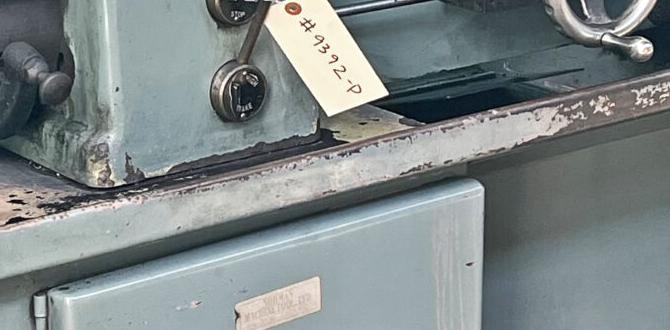

Have you ever used a metal lathe? It’s a powerful tool that can shape metal with precision. But what happens when the lead screw nut becomes loose or broken? Suddenly, that amazing tool becomes difficult to control and frustrating to use.

You might wonder, “How can I fix a lead screw nut?” This common issue can stop your projects in their tracks. Luckily, fixing a metal lathe lead screw nut is easier than you might think. With a few simple steps, you can get back to creating with confidence.

Did you know that some metal lathes are over a century old? People still use them because they are reliable and durable. However, like anything else, they need maintenance. Addressing the lead screw nut problem quickly is key. It can save you time and helps you complete your projects smoothly.

So, what’s the first step to tackling this fix? Let’s dive into the details. You’ll be glad you did, and your lathe will thank you!

Metal Lathe Lead Screw Nut Fix: A Comprehensive Guide

Metal Lathe Lead Screw Nut Fix

Fixing a lead screw nut on a metal lathe might sound daunting, but it can be simple! A loose nut can cause problems like poor machining and inaccurate cuts. To solve this, you can often replace or adjust the lead screw nut easily. Regular checks can prevent issues and keep your lathe working well. Did you know that a well-maintained lathe can last for decades? Discovering this fix can save you time and money in the long run!Understanding the Lead Screw Nut

Definition and function of the lead screw nut in metal lathes. Importance of lead screw nut in precision machining.The lead screw nut is a nifty part of metal lathes. Think of it as the best buddy of the lead screw! This little guy helps move the machine’s tools smoothly along the material, ensuring precision. Without it, the lathe would wobble like a jelly on a rollercoaster. In precision machining, the lead screw nut is vital. It makes sure everything fits snugly and works correctly. Remember, a happy lead screw nut means happy machining!

| Function | Importance |

|---|---|

| Guides the tool movement | Ensures accurate cuts |

| Supports the lead screw | Reduces wear and tear |

| Transmits rotation to linear motion | Helps achieve precise dimensions |

Common Problems with Lead Screw Nuts

Signs of wear and tear in lead screw nuts. Impact of a malfunctioning lead screw nut on lathe performance.Lead screw nuts can show signs of wear over time. You might notice issues like unusual noises or slipping movement. These problems can greatly affect your lathe’s performance. If the lead screw nut fails, it can cause jagged cuts and uneven surfaces on your workpieces. Regular checks help catch these problems early, ensuring smooth operation and better accuracy.

How can I tell if my lead screw nut needs fixing?

Look for signs like noises, slipping, and rough movements. These may mean your lead screw nut is wearing out.

Impact of a malfunctioning lead screw nut:

- Unstable cuts

- Increased wear on other parts

- Poor surface finish

Assessing Lead Screw Nut Damage

Methods to inspect and diagnose lead screw nut issues. Tools and techniques for accurate assessments.When checking your lead screw nut for trouble, look closely! Start by examining for any wear, cracks, or unusual bumps. A flashlight can help you spot hidden issues. Use a caliper to measure the nut’s dimensions; it should fit snugly on the screw. If it’s loose or too tight, you know there’s a problem. Remember, finding issues early can save you from bigger headaches later! A confused lead screw nut is about as useful as a chocolate teapot!

| Inspection Method | Tools Needed |

|---|---|

| Visual Inspection | Flashlight, Magnifying Glass |

| Dimensional Check | Caliper, Ruler |

| Movement Test | Allen Wrench (if applicable) |

Step-by-Step Guide to Fixing Lead Screw Nuts

Essential tools and materials required for the repair. Detailed instructions for disassembly, inspection, and replacement.To fix the lead screw nuts, gather these important tools:

- Wrench

- Screwdriver

- Replacement nuts

- Lubricant

- Measuring tape

Start by turning off the machine. Next, remove the cover carefully. Inspect the lead screw and nuts for wear. If they look damaged, replace them with new ones. Reassemble the parts in reverse order. Don’t forget to add some lubricant for smooth operation!

What tools do you need to fix a lead screw nut?

You need a wrench, screwdriver, replacement nuts, lubricant, and measuring tape.

Preventative Maintenance Tips for Lead Screw Nuts

Best practices to extend the life of lead screw nuts. Recommended maintenance frequency and procedures.To keep lead screw nuts working well, regular care is important. Here are some best practices:

- Clean the nuts regularly to remove dust and debris.

- Apply a light lubricant to prevent wear.

- Check for loose parts and tighten as needed.

- Inspect for damage or signs of wear every month.

Doing these tasks often can help extend the life of lead screw nuts. Regular maintenance saves time and money in the long run. Remember, a little care goes a long way!

How often should I maintain lead screw nuts?

Check lead screw nuts monthly for wear. This keeps them in good shape and helps avoid bigger problems later.

Alternative Solutions and Upgrades

Comparison of standard vs. aftermarket lead screw nuts. Pros and cons of adjustable and nonadjustable options.Choosing between standard and aftermarket lead screw nuts can be tricky. Aftermarket options often offer better customization. They may improve performance but can be more expensive. Standard parts are easier to find but sometimes lack updates. It’s wise to consider adjustable versus nonadjustable nuts:

- Adjustable Nuts: These let you fine-tune the fit. More control is a big plus.

- Nonadjustable Nuts: These are simple and reliable but don’t allow for adjustments.

Overall, think about what you need most. Performance? Cost? Each choice has its own benefits.

What are the benefits of aftermarket lead screw nuts?

Aftermarket lead screw nuts can enhance performance, offer better fit, and possibly extend the life of your lathe.

Is it better to have adjustable or nonadjustable nuts?

Adjustable nuts provide more control, while nonadjustable ones are simpler and more reliable.

Frequently Asked Questions (FAQs)

Common queries regarding lead screw nut repairs. Troubleshooting tips for ongoing issues.Many people have questions about fixing the lead screw nut on a metal lathe. Here are some common queries.

How do I know if my lead screw nut is worn out?

The signs include:

- Increased backlash: You notice a lot of movement in the handle.

- Surface wear: The nut looks rough or uneven.

- Difficulty moving: The screw feels stiff or stuck.

What should I check if my lathe still has issues?

If you have ongoing problems, inspect these parts:

- Alignment: Make sure everything is straight.

- Lubrication: Ensure you use enough oil.

- Set screws: Tighten any loose screws holding the nut.

By following these tips, you can keep your lathe running well. Remember, regular checks can prevent a lot of problems!

Resources for Further Learning

Recommended books, websites, and forums for metalworking enthusiasts. How to connect with professional machinists for advice.| Resource Type | Recommendations |

|---|---|

| Books | “Machinery’s Handbook” and “The Essential Guide to Metalworking” |

| Websites | Metalworking Fun and CNC Zone |

| Forums | The Home Machinist and Practical Machinist |

Looking to dive deeper into metalworking? Grab some great books like “Machinery’s Handbook”, which is like a treasure chest for machinists. Search online! Websites such as Metalworking Fun will help you learn and connect. Don’t forget the forums! They’re buzzing with pros ready to share tips. If you want to chat with experienced machinists, join local workshops and ask questions. Remember, even the best need help sometimes!

Conclusion

In summary, fixing the lead screw nut on your metal lathe can improve accuracy and performance. Understanding its function helps you maintain your equipment better. You can replace or adjust it easily with the right tools. We encourage you to explore more guides or videos to learn these skills. Happy machining, and keep your lathe in top shape!FAQs

Sure! Here Are Five Related Questions On The Topic Of Fixing A Metal Lathe Lead Screw Nut:To fix a metal lathe lead screw nut, first, you need to find the problem. Check if the nut is worn out or too loose. You can replace it with a new one if needed. Make sure everything is clean and tight before you start using it again. Always be careful when working with tools and machines!

Sure! Please provide the question you’d like me to answer.

What Are The Common Signs That Indicate A Lead Screw Nut Needs To Be Repaired Or Replaced On A Metal Lathe?If your metal lathe isn’t moving smoothly, it might be time for a check. You might notice weird noises when you use it. The lead screw nut may feel loose or wobbly. Also, if it’s hard to turn or gets stuck, that’s a sign. Look for wear or damage, too, like cracks or pieces missing.

How Can I Determine The Correct Size And Type Of Lead Screw Nut For My Specific Metal Lathe Model?To find the right lead screw nut for your metal lathe, start by checking your lathe’s manual. It usually has the size you need. You can also measure the old nut with a ruler. Look for a nut that fits snugly and works well with your lead screw. If you’re unsure, ask a friend or a local expert for help.

What Tools And Materials Are Required To Replace A Worn Lead Screw Nut On A Metal Lathe?To replace a worn lead screw nut on a metal lathe, you need a few tools and materials. First, get a wrench to loosen bolts. Then, have a screwdriver ready for other screws. You will also need a new lead screw nut to replace the old one. Lastly, don’t forget some oil to help the parts move smoothly after you finish.

Are There Any Specific Techniques For Adjusting A Lead Screw Nut To Improve Precision And Reduce Backlash On A Metal Lathe?Yes, there are ways to adjust a lead screw nut for better precision and less backlash. First, you can loosen the screws that hold the nut in place. Then, gently move the nut closer to the lead screw. Tighten the screws again while making sure it’s not too tight. Finally, check if the movement feels smooth and steady.

What Preventative Maintenance Steps Can I Take To Prolong The Lifespan Of The Lead Screw Nut On My Metal Lathe?To keep the lead screw nut on your metal lathe working well, clean it regularly. Use a soft cloth to wipe away dust and oil. You should also check it for wear and tear. It’s good to add a little grease to help it move smoothly. Finally, make sure everything is tight, so it doesn’t move too much.