Imagine crafting something amazing with a metal lathe! It’s exciting but not without danger. Did you know that even the tiniest mistake can cause big trouble? A metal lathe risk assessment checklist can help keep you safe. Picture a knight going into battle. He needs his armor just like you need the right safeguards when using a lathe. Ever wonder how many accidents happen in workshops? It’s more than you think! A simple checklist can be your shield.

Many people don’t think about risks. They focus only on their project. Wouldn’t it be great if you had a quick, easy guide to stay safe? Think about it. You wouldn’t cross the street without looking both ways, right? A risk assessment checklist is like checking both ways, but for using a lathe.

Do you want to make sure that your fun project stays fun? Let’s explore how a few simple steps can prevent accidents. Ready to dive into the world of metal lathe safety? It starts with understanding and preparing with the right tools.

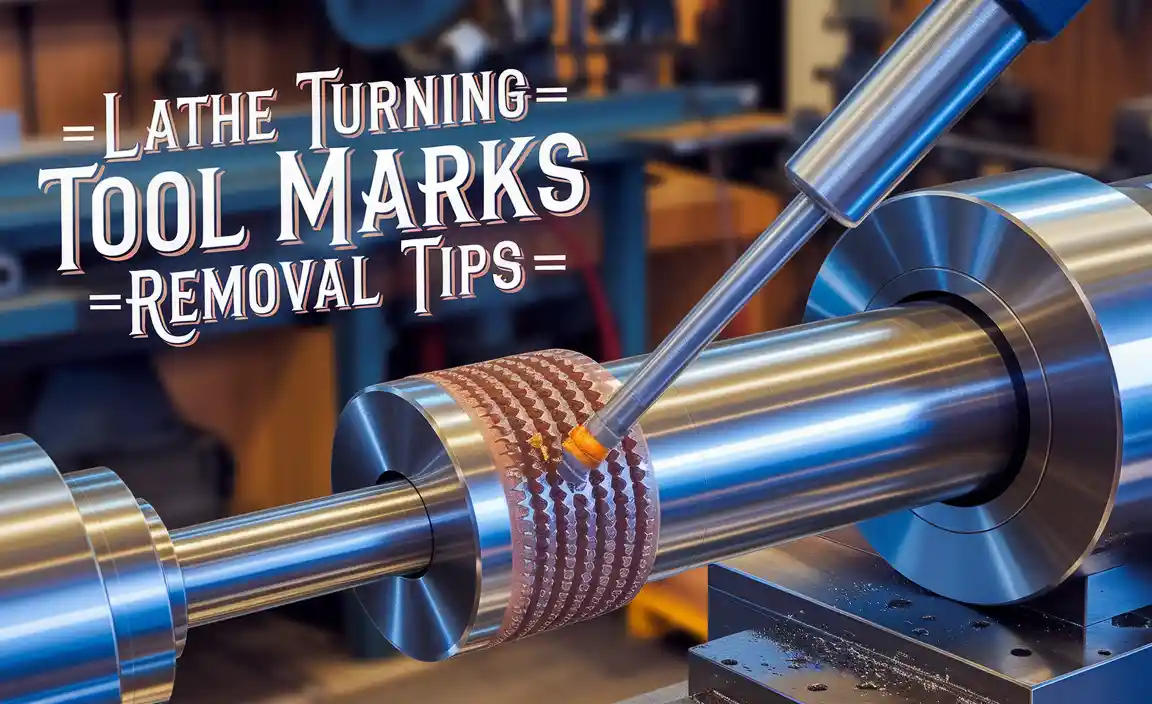

Comprehensive Metal Lathe Risk Assessment Checklist

Metal Lathe Risk Assessment Checklist

Imagine you’re crafting a beautiful sculpture from a metal block. A metal lathe helps with this, but there’s a catch. It can be risky if you’re not careful. That’s why a metal lathe risk assessment checklist is vital. This checklist keeps you safe by ensuring you have the right protective gear, understand machine controls, and know emergency procedures. Did you know that using the checklist reduces accident chances? Stay safe while creating wonders!Understanding the Importance of Risk Assessment in Metal Lathing

Explaining the significance of risk assessment in the workplace. The impact of proper assessments on safety and efficiency.Risk assessment is key in metal lathing. It keeps workers safe and helps in doing tasks right. By checking dangers, we avoid accidents and make work smooth. Why is this vital? Because it protects lives and ensures everything runs well. Think of it as a shield protecting the workshop. Proper checks lead to fewer injuries and more success.

Why is risk assessment crucial in metal lathing?

Risk assessment is crucial because it spots dangers before work starts. This keeps everyone safe and operations smooth. Imagine it as finding hidden traps before stepping forward. By knowing risks, we can make better plans and reduce harm.

Effective risk assessment gives workers confidence. They know someone is watching out for them. A safe place to work makes every day better, and jobs get done faster. In sum, risk assessment is like a game plan. It helps identify the potential hazards and ensures workers’ safety, leading to increased productivity and efficiency.

Identifying Common Hazards Associated with Metal Lathes

Highlighting typical physical and operational hazards. Potential consequences of unaddressed hazards.Metal lathes can be dangerous if hazards are not recognized. Common risks include:

- Moving Parts: They can pinch or grab fingers.

- Sharp Edges: Cuts can happen from tools or materials.

- Flying Debris: Chips can fly and hit eyes.

- Noise: Loud sounds can cause hearing loss.

If these hazards are ignored, severe injuries can occur, including:

- Loss of Limbs: Fingers or hands can be lost.

- Eye Injuries: Vision loss is possible without protective gear.

- Hearing Damage: Prolonged noise exposure can be harmful.

Awareness of these risks is key for safety.

What should I look out for with metal lathes?

Look out for moving parts, sharp tools, and chips flying around your workspace. These hazards may lead to serious injury if not addressed promptly.

Essential Safety Precautions for Operating a Metal Lathe

Personal protective equipment (PPE) requirements. Safe operating procedures and best practices.Safety is super important when using a metal lathe. First off, wearing the right Personal Protective Equipment (PPE) is key. This means safety goggles, gloves, and sturdy shoes. They protect you from flying metal bits. Second, follow safe operating procedures. Always keep your workspace clean and organized. Don’t wear loose clothing; it might become friends with the lathe! Finally, knowing how to use the lathe properly is essential. Before you start, double-check everything. Remember, safety first, fun second!

| PPE Item | Purpose |

|---|---|

| Safety Goggles | Protect eyes from debris |

| Gloves | Prevent cuts and scrapes |

| Sturdy Shoes | Protect feet from heavy objects |

Developing a Customized Metal Lathe Risk Assessment Checklist

Key elements to include in a checklist. Steps in customizing the checklist to fit specific environments.Creating a metal lathe risk assessment checklist is like building a safety net for your workshop. Start by including key elements like machine settings, operator training, and personal protective equipment. Next, customize your checklist by assessing unique factors in your workspace, like space layout or specific materials used. Don’t forget to add a pinch of humor—like asking if everyone knows where the fire extinguisher is or if it’s playing hide and seek! Check out the table below for a clear overview:

| Key Elements | Customization Steps |

|---|---|

| Machine settings | Identify unique workspace factors |

| Operator training | Gather team feedback |

| Protective equipment | Consider specific materials |

Step-by-Step Guide to Performing a Risk Assessment

Detailed steps for conducting an effective risk evaluation. Tools and techniques for hazard documentation and analysis.To conduct a thorough risk assessment, start with identifying hazards in your workspace. Make a list of things that could go wrong and check them off as you go. Next, think about who might be affected. Is it just you, or does the whole team need a heads-up? Use tools like checklists or charts for easy tracking. Also, gather input from coworkers; even the funniest guy in the shop might have valuable insights!

| Step | Action |

|---|---|

| 1 | Identify Hazards |

| 2 | Evaluate Risks |

| 3 | Document Findings |

| 4 | Review Regularly |

Once you’ve documented these points, take time to prioritize the risks. Note which areas could cause the most trouble. And remember, a well-documented risk assessment is like having a safety net. It won’t catch you if you slip, but it could prevent you from taking the leap in the first place!

Implementing Corrective Measures and Mitigation Strategies

Strategies for mitigating identified risks. Procedures for rectifying hazardous situations.To keep everyone safe, it’s important to act quickly when risks are found. First, make a list of all the danger spots on your metal lathe. Then, use these methods to reduce the risks:

- Install safety guards to prevent accidents.

- Use warning signs to remind everyone to stay alert.

- Train staff on safe operating practices.

- Regularly check equipment for any problems.

If a dangerous situation arises, follow these steps:

- Stop the machine immediately.

- Clear the area of any workers.

- Report the problem to a supervisor.

- Fix the issue before starting again.

What are the key steps for hazard correction?

Identify the risk, stop work, inform a supervisor, and make necessary repairs or adjustments. This will help keep everyone safe!

Training and Educating Personnel on Metal Lathe Safety

Importance of ongoing employee training. Recommended training programs and resources.Keeping everyone safe is key when using metal lathes. Regular training helps employees remember safety rules. Think of it like practicing to ride a bike; the more you do it, the better you get! Consider these fun training programs:

| Program Name | Description |

|---|---|

| Safety First! | Focuses on essential safety practices and emergency procedures. |

| Hands-On Training | Practical sessions for real-life metal lathe operation. |

| Safety Leaders | Train employees to become safety mentors for others. |

Getting trained is like wearing a seatbelt; it saves lives! Remember, a well-trained worker is a happy worker. So, keep up with ongoing training, and everyone can work safely! It’s way less dramatic than a surprise plot twist in a movie!

Regular Review and Updating of the Risk Assessment Checklist

Importance of periodic reviews and updates. Indicators that necessitate a reassessment.It’s crucial to check your risk assessment checklist regularly. Why? Because things change! New tools may pop up, or old ones might wear out. Keeping the checklist fresh helps spot possible dangers before they surprise you, like a sneaky raccoon in your trash can. If an accident happens or if you hire new workers, it’s time for an update. Here’s a quick table showing signs you need to reassess:

| Indicator | Action Required |

|---|---|

| New Machines | Update checklist |

| Injuries Reported | Review risk |

| Changes in Staff | Reassess |

Remember, a checklist that sits unused is about as helpful as a chocolate teapot! Keep it alive and kicking to ensure safety in your workplace.

Documenting and Reporting Risk Assessment Findings

Best practices for documentation and reporting. Utilizing reports to improve safety measures and protocols.Keeping track of safety findings is very important. Good documentation helps everyone stay safe. Reports should be clear and easy to read. Use the following best practices:

- Write down all safety risks clearly.

- Update documents regularly.

- Share reports with your team.

Using these reports can help improve safety measures. For example, teams can spot problems and change rules. This makes the work environment better for everyone.

Why is risk assessment reporting important?

Risk assessment reporting highlights safety issues and helps teams fix them. It also shows how well safety rules are working. Teams can share successes and learn from mistakes.

Conclusion

A metal lathe risk assessment checklist helps keep you safe while using the machine. It guides you to identify hazards, check safety gear, and ensure proper training. Use it before each project to prevent accidents. Explore more on workshop safety to stay informed and protected. Always prioritize safety and encourage others to do the same.FAQs

Sure! Here Are Five Related Questions For A Metal Lathe Risk Assessment Checklist:Sure! Here are five questions we can ask for a metal lathe safety checklist: 1. Do you wear safety glasses to protect your eyes? 2. Is the area around the lathe clean and free of clutter? 3. Are your long hair and loose clothes tied back or tucked in? 4. Is the machine properly working before you start using it? 5. Do you know the emergency stop button’s location? These questions help keep you safe while using the lathe!

Sure! Just let me know what question you’d like me to answer.

What Specific Safety Precautions Should Be Taken Before Operating The Metal Lathe To Prevent Injuries?Before using a metal lathe, you should always wear safety glasses to protect your eyes. Tie back long hair and remove loose clothing to avoid getting caught in the machine. Make sure your work area is clean and free of clutter. Check that all guards and safety devices are in place and working properly. Lastly, never use the lathe without proper training or supervision.

Are All Operators Trained And Certified In Metal Lathe Operation And Safety Protocols?Yes, all operators need to be trained and certified to use a metal lathe. This means they learn how to use the machine safely. They also learn important safety rules to follow. Training helps keep everyone safe while working. It’s very important that they know what to do!

What Personal Protective Equipment (Ppe) Is Required For Employees Working With The Metal Lathe?When you work with a metal lathe, you need to wear special gear to stay safe. First, put on safety goggles to protect your eyes from flying bits of metal. Next, wear gloves to keep your hands safe from sharp edges. A face mask helps keep dust out of your lungs. Lastly, wear sturdy shoes to protect your feet.

How Is The Work Area Organized To Prevent Hazards, Such As Ensuring Clear Access To Emergency Stop Controls?We keep the work area neat and tidy. This way, you can easily find things. We make sure emergency stop buttons are clear and easy to reach. This helps everyone stay safe. Always look for obstacles and remove anything blocking your way!

Are Regular Maintenance And Inspection Schedules In Place For The Metal Lathe To Ensure It Is Functioning Safely And Effectively?Yes, we have regular maintenance and inspection schedules for the metal lathe. This means we check it often to make sure it works well. We clean it, check for problems, and fix anything that’s broken. This helps keep everyone safe and makes sure the lathe works properly.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions For A Metal Lathe Risk Assessment Checklist:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are five questions we can ask for a metal lathe safety checklist: 1. Do you wear safety glasses to protect your eyes? 2. Is the area around the lathe clean and free of clutter? 3. Are your long hair and loose clothes tied back or tucked in? 4. Is the machine properly working before you start using it? 5. Do you know the emergency stop button’s location? These questions help keep you safe while using the lathe!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Just let me know what question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Specific Safety Precautions Should Be Taken Before Operating The Metal Lathe To Prevent Injuries?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Before using a metal lathe, you should always wear safety glasses to protect your eyes. Tie back long hair and remove loose clothing to avoid getting caught in the machine. Make sure your work area is clean and free of clutter. Check that all guards and safety devices are in place and working properly. Lastly, never use the lathe without proper training or supervision.”}},{“@type”: “Question”,”name”: “Are All Operators Trained And Certified In Metal Lathe Operation And Safety Protocols?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, all operators need to be trained and certified to use a metal lathe. This means they learn how to use the machine safely. They also learn important safety rules to follow. Training helps keep everyone safe while working. It’s very important that they know what to do!”}},{“@type”: “Question”,”name”: “What Personal Protective Equipment (Ppe) Is Required For Employees Working With The Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When you work with a metal lathe, you need to wear special gear to stay safe. First, put on safety goggles to protect your eyes from flying bits of metal. Next, wear gloves to keep your hands safe from sharp edges. A face mask helps keep dust out of your lungs. Lastly, wear sturdy shoes to protect your feet.”}},{“@type”: “Question”,”name”: “How Is The Work Area Organized To Prevent Hazards, Such As Ensuring Clear Access To Emergency Stop Controls?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “We keep the work area neat and tidy. This way, you can easily find things. We make sure emergency stop buttons are clear and easy to reach. This helps everyone stay safe. Always look for obstacles and remove anything blocking your way!”}},{“@type”: “Question”,”name”: “Are Regular Maintenance And Inspection Schedules In Place For The Metal Lathe To Ensure It Is Functioning Safely And Effectively?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, we have regular maintenance and inspection schedules for the metal lathe. This means we check it often to make sure it works well. We clean it, check for problems, and fix anything that’s broken. This helps keep everyone safe and makes sure the lathe works properly.”}}]}