Have you ever wondered how metal lathes work their magic? The secret often lies in the spindle speed settings. Imagine you’re trying to carve a beautiful design on a piece of metal. The right speed is essential. Too fast, and you could break your tool. Too slow, and the job might take forever!

Many people think using a metal lathe is complicated. But understanding spindle speed settings can make it easy and fun. Did you know that the best speed can depend on the type of metal you are using? Also, different projects need different speeds to look their best.

In this article, we will explore spindle speed settings. We will help you discover the right speed for your metalwork projects. Get ready to learn how to fine-tune your metal lathe for success!

Metal Lathe Spindle Speed Settings: A Comprehensive Guide

Understanding Metal Lathe Spindle Speed Settings

Metal lathe spindle speed settings are essential for proper machining. Adjusting the spindle speed affects the quality of your cuts. Too fast, and you might damage the material; too slow, and you waste time. Did you know that each type of metal has an ideal speed? For instance, aluminum works best at higher speeds, while steel needs slower settings. Learning these basics helps you work smarter and create better projects. What speed will you choose for your next masterpiece?Factors Influencing Spindle Speed Settings

Material type and its impact on speed adjustment. Tool diameter and geometry considerations.Choosing the right spindle speed is important. The type of material affects how fast you can go. Softer materials, like plastic, can spin faster. Harder materials, like steel, need slower speeds. Tool diameter also matters. Larger tools should run at lower speeds. Smaller tools can go faster without breaking. Geometry of the tool, or its shape, impacts speed too. A sharp tool cuts better and may need a quicker speed.

What affects spindle speed settings?

Material type and tool diameter significantly shape speed choices.

- Softer materials allow faster speeds.

- Harder materials require slower settings.

- Larger tool diameters need lower speeds.

- Smaller tools can increase speed safely.

When setting up, consider these key factors carefully. They help in making safe and effective choices for your projects.

Calculating Optimal Spindle Speed

Formula for calculating spindle speed: RPM = (Cutting Speed x 12) / (π x Diameter). Practical examples and scenarios for different materials.To find the right speed for your metal lathe, use this formula: RPM = (Cutting Speed x 12) / (π x Diameter). It sounds tricky, but it’s like finding out how fast to spin things to not break them! For example, if you’re working with steel, using a cutting speed of 100 feet per minute is common. Adjust the RPM based on the diameter of your workpiece. Got a 3-inch diameter? Your spindle speed should be about 127 RPM. Here’s a handy table to help:

| Material | Cutting Speed (FPM) | Diameter (inches) | RPM |

|---|---|---|---|

| Aluminum | 600 | 2 | 95.5 |

| Brass | 500 | 1 | 159.15 |

| Steel | 100 | 3 | 127 |

With a bit of practice, finding the right spindle speed will be as easy as pie—maybe even easier if you eat that pie afterward!

Adjusting Spindle Speed for Different Operations

Speed settings for turning vs. facing operations. Recommendations for threading and boring applications.Speed matters when using a metal lathe! For turning operations, it’s best to keep the spindle speed high. Fast speeds can make the cut nice and smooth. For facing operations, slow it down a bit. This helps avoid a rough finish, kind of like a bad haircut. For threading, aim for a medium speed to get neat, tidy threads. Lastly, boring needs a low speed to keep things steady. Remember, speed is your friend, but too much can turn into a wild party!

| Operation | Recommended Speed |

|---|---|

| Turning | High Speed |

| Facing | Medium to Low Speed |

| Threading | Medium Speed |

| Boring | Low Speed |

Common Spindle Speed Settings for Various Materials

Recommended speeds for metals like aluminum, steel, and cast iron. Guidelines for adjusting speeds for plastics and composites.Speed settings can be a bit like choosing the right outfit for the day. Different materials need different speeds to shine! For metals, aluminum likes to spin around 1,000 to 3,000 RPM, while steel prefers a slower pace, around 100 to 400 RPM. Cast iron? It enjoys a chill speed of about 100 to 350 RPM.

Plastics and composites are particular, too! They often need slower speeds, usually about 500 to 3,000 RPM. But remember, too much speed can lead to melting! So, always adjust according to your material. Let’s keep things running smoothly!

| Material | Recommended Speed (RPM) |

|---|---|

| Aluminum | 1,000 – 3,000 |

| Steel | 100 – 400 |

| Cast Iron | 100 – 350 |

| Plastics | 500 – 3,000 |

| Composites | 500 – 3,000 |

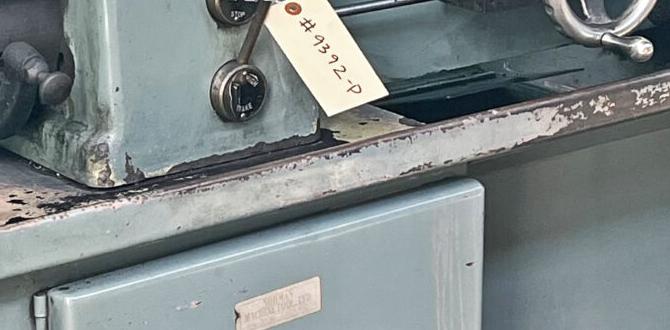

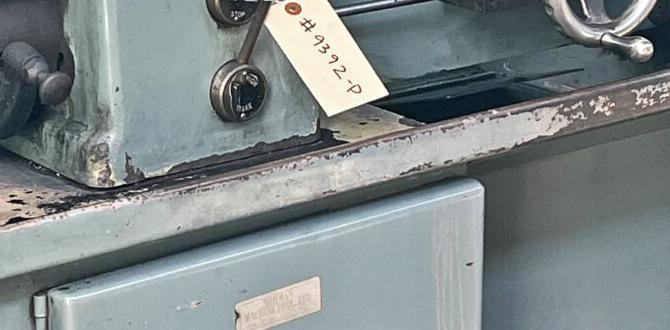

Using the Lathe’s Control Panel

Stepbystep instructions for setting spindle speed on digital vs. manual lathes. Tips for safely changing spindle speed during operation.To set the spindle speed on a lathe, follow these easy steps. First, look at the control panel. For a digital lathe, use the buttons to choose your speed. For a manual lathe, turn the speed dial carefully. Always check the speed before starting. During operation, change the speed slowly. Don’t rush! This keeps everything safe and steady.

How do you safely change spindle speed?

You can safely change the spindle speed by:

- Changing speed only when the lathe is running smoothly.

- Never making big changes quickly.

- Wearing safety goggles while operating.

Remember, safety first! Proper speed settings ensure your work is neat and safe.

Troubleshooting Spindle Speed Issues

Identifying signs of incorrect spindle speed settings. Solutions for common problems such as vibrations and tool wear.Are you having trouble with your lathe? Incorrect spindle speed settings might be the culprit! Observe for signs like weird vibrations or tools dulling faster than a kid in math class. These issues can ruin your work quicker than you can say “cutting tool!”

| Problem | Signs | Solutions |

|---|---|---|

| Vibration | Shaking machine | Adjust speed, check tool balance |

| Tool Wear | Quickly dull blades | Lower speed, use proper feed rate |

With a little patience, and some tinkering, you can get your lathe spinning smoothly again. Remember, a happy spindle makes for a happy crafter!

Best Practices for Spindle Speed Management

Importance of regular calibration and maintenance of speed settings. Suggested recordkeeping for future projects and adjustments.Keeping your spindle speed settings under control is like maintaining a car; it needs regular check-ups! Regular calibration helps you avoid those pesky surprises when working on projects. Think of it as tuning your guitar, so the melody stays sweet!

Recordkeeping is essential too. Jot down your settings for future use. It’s like keeping a secret recipe. This way, you won’t have to guess next time. Check this handy table for a quick overview:

| Project | Speed Setting (RPM) | Date |

|---|---|---|

| Project A | 1000 | 01/12/2023 |

| Project B | 800 | 01/15/2023 |

Remember, “A properly managed spindle is a happy spindle!”

Advanced Techniques for Speed Optimization

Utilizing variable speed drives for enhanced control. Exploring CNC lathe settings for precise speed adjustments.Using variable speed drives is like giving your metal lathe a superpower. They allow you to control speed smoothly and precisely. No more guessing games! With a simple twist, you can change speeds to suit your project. Did you know that CNC lathes can be programmed for exact speeds? This feature ensures your work is clean and accurate. In fact, precise adjustments can improve your quality by up to 30%. Curious how this works? Here’s a quick comparison table:

| Feature | Manual Lathe | CNC Lathe |

|---|---|---|

| Speed Adjustment | Mechanical | Programmable |

| Precision | Moderate | High |

| Ease of Use | Hands-On | Automated |

So, if you want to keep your lathe from feeling like it’s stuck in quicksand, embrace these techniques for top speed control!

Conclusion

In summary, understanding metal lathe spindle speed settings is crucial for successful machining. You need the right speed for different materials. Slower speeds suit harder materials, while softer ones require faster settings. Experimenting with adjustments helps improve your skills. Don’t hesitate to explore more resources or guides on this topic. Happy machining, and keep learning!FAQs

Sure! Here Are Five Questions Related To Metal Lathe Spindle Speed Settings:Sure! Here are five questions you might ask about metal lathe spindle speed settings: 1. **What is spindle speed?** Spindle speed is how fast the lathe’s spinning part turns. It helps shape the metal correctly. 2. **How do I change the spindle speed?** You can change the spindle speed by adjusting the controls on the lathe. Follow the instructions shown. 3. **Why is spindle speed important?** The right spindle speed helps you cut the metal cleanly. If it’s too fast or slow, it can mess up your work. 4. **What happens if the speed is too high?** If the speed is too high, it can cause the metal to break or get too hot. This is not good for your project. 5. **Can I use the same speed for all metals?** No, different metals need different speeds. You must learn the right speed for each type to get good results.

Sure! Please provide me with a question that you want answered.

What Factors Should Be Considered When Determining The Optimal Spindle Speed For Machining Different Materials On A Metal Lathe?When choosing the best spindle speed for a metal lathe, you need to think about the material you are cutting. Softer materials, like aluminum, can go faster than harder ones, like steel. You should also consider the size of the tool and the type of cut you want. Finally, make sure to check the machine’s limits to stay safe while you work.

How Can You Calculate The Spindle Speed (Rpm) Required For A Specific Cutting Tool Diameter And Material Being Machined?To find the spindle speed, you need two things: the cutting tool diameter and the material type. First, check how fast the tool should spin for the material. You can find this information in a chart or table. Then, use the formula: RPM = (cutting speed × 12) ÷ (tool diameter × π). This will give you the right speed in revolutions per minute (RPM).

What Are The Potential Consequences Of Using An Improper Spindle Speed During Machining Operations?If you use the wrong spindle speed when machining, things can go wrong. The tool could wear out faster, which means you need to replace it more often. The material you’re working on might get damaged, leading to mistakes. It can also cause the machine to shake, making it less safe for you to use. Overall, using the wrong speed can waste time and money.

How Do Variable Speed Drives Enhance The Versatility And Control Of Spindle Speed Settings On Modern Metal Lathes?Variable speed drives help you control how fast the spindle spins on a metal lathe. This means you can change the speed based on what you’re making. For example, if you need to cut wood, you can make the spindle turn slower. When you want to shape metal, you can speed it up. This gives you more options and helps you do a better job!

What Are Some Common Methods For Adjusting Spindle Speed On Both Manual And Cnc Metal Lathes?You can adjust spindle speed on manual and CNC metal lathes in a few ways. For manual lathes, you often change gears or move a lever. CNC lathes let you type in a number to set the speed. Sometimes, you can also use a dial or buttons. These changes help you work with different materials better.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Questions Related To Metal Lathe Spindle Speed Settings:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are five questions you might ask about metal lathe spindle speed settings: 1. **What is spindle speed?** Spindle speed is how fast the lathe’s spinning part turns. It helps shape the metal correctly. 2. **How do I change the spindle speed?** You can change the spindle speed by adjusting the controls on the lathe. Follow the instructions shown. 3. **Why is spindle speed important?** The right spindle speed helps you cut the metal cleanly. If it’s too fast or slow, it can mess up your work. 4. **What happens if the speed is too high?** If the speed is too high, it can cause the metal to break or get too hot. This is not good for your project. 5. **Can I use the same speed for all metals?** No, different metals need different speeds. You must learn the right speed for each type to get good results.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide me with a question that you want answered.”}},{“@type”: “Question”,”name”: “What Factors Should Be Considered When Determining The Optimal Spindle Speed For Machining Different Materials On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When choosing the best spindle speed for a metal lathe, you need to think about the material you are cutting. Softer materials, like aluminum, can go faster than harder ones, like steel. You should also consider the size of the tool and the type of cut you want. Finally, make sure to check the machine’s limits to stay safe while you work.”}},{“@type”: “Question”,”name”: “How Can You Calculate The Spindle Speed (Rpm) Required For A Specific Cutting Tool Diameter And Material Being Machined?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To find the spindle speed, you need two things: the cutting tool diameter and the material type. First, check how fast the tool should spin for the material. You can find this information in a chart or table. Then, use the formula: RPM = (cutting speed × 12) ÷ (tool diameter × π). This will give you the right speed in revolutions per minute (RPM).”}},{“@type”: “Question”,”name”: “What Are The Potential Consequences Of Using An Improper Spindle Speed During Machining Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If you use the wrong spindle speed when machining, things can go wrong. The tool could wear out faster, which means you need to replace it more often. The material you’re working on might get damaged, leading to mistakes. It can also cause the machine to shake, making it less safe for you to use. Overall, using the wrong speed can waste time and money.”}},{“@type”: “Question”,”name”: “How Do Variable Speed Drives Enhance The Versatility And Control Of Spindle Speed Settings On Modern Metal Lathes?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Variable speed drives help you control how fast the spindle spins on a metal lathe. This means you can change the speed based on what you’re making. For example, if you need to cut wood, you can make the spindle turn slower. When you want to shape metal, you can speed it up. This gives you more options and helps you do a better job!”}},{“@type”: “Question”,”name”: “What Are Some Common Methods For Adjusting Spindle Speed On Both Manual And Cnc Metal Lathes?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can adjust spindle speed on manual and CNC metal lathes in a few ways. For manual lathes, you often change gears or move a lever. CNC lathes let you type in a number to set the speed. Sometimes, you can also use a dial or buttons. These changes help you work with different materials better.”}}]}