Imagine you’re building a cool race car model. Ever wonder how certain parts fit so perfectly? It’s no magic trick; it’s the work of a metal lathe thread cutting dial. These special dials are like a secret tool. They help make precise cuts on metal rods. Without them, car parts might not fit well!

Metal lathe machines hold the key to many things we use daily. Have you ever seen those giant screws? Or maybe you’ve noticed bolts that twist so smoothly? It’s all because of this tiny dial.

Here’s a fun fact: skilled workers didn’t always have them. Can you believe they used to do this by hand? Now, the dial makes it all easy and quick.

But how exactly does it work? And why is it so important for these perfect fits? Let’s dive in and uncover the secrets behind this fascinating tool.

Mastering Metal Lathe Thread Cutting Dial Techniques Thread Cutting On A Metal Lathe Is A Crucial Skill For Machinists, And The Thread Cutting Dial Is An Essential Tool In This Process. Understanding How To Properly Utilize A Thread Cutting Dial Can Significantly Enhance The Precision And Efficiency Of Your Threading Projects. What Is A Thread Cutting Dial? A Thread Cutting Dial Is A Device Mounted On The Apron Of A Lathe. It Is Specifically Used To Synchronize The Rotation Of The Lathe’S Leadscrew With The Spindle, Allowing The Machinist To Accurately Cut Threads On A Workpiece. By Aligning The Thread Cutting Process With The Dial’S Indications, One Can Ensure That The Threading Starts At The Same Point On Every Subsequent Pass. Importance Of A Metal Lathe In Thread Cutting A Metal Lathe Is A Versatile Machine Tool Capable Of Performing Multiple Operations, Including Cutting, Sanding, Knurling, And Threading. It Is Especially Vital When Precision And Custom Thread Fabrication Are Required. The Thread Cutting Dial, In Conjunction, Streamlines The Process Of Engaging The Half-Nuts At The Right Time, Thereby Enabling Consistent And Accurate Threading Operations. Setting Up The Thread Cutting Dial 1. **Engage The Half-Nut Lever**: Before Starting The Threading Process, Make Sure The Lathe Is Set To The Correct Pitch Using The Gear On The Leadscrew. The Half-Nut Lever, When Engaged, Connects The Carriage To The Leadscrew, Which Is Fundamental For Threading. 2. **Zero The Dial**: It’S Important To Zero The Thread Cutting Dial At The Beginning Of The Threading Process. This Step Ensures That Each Pass Of The Threading Tool Aligns Perfectly With The Previous One. 3. **Follow The Dial’S Indicators**: As You Perform The Threading, Align The Position Of The Dial With The Indicator Marks To Ensure Each Threading Pass Begins In The Correct Location. Tips For Using The Thread Cutting Dial – **Use The Right Gear**: Depending On The Thread Pitch, Ensure Your Lathe’S Gearing Is Set Up Correctly To Work In Sync With The Leadscrew. – **Consistent Starting Points**: Always Engage The Half-Nut Lever At The Same Indicator Mark On The Thread Cutting Dial For Each Pass. – **Regular Maintenance**: Regularly Clean And Lubricate The Dial To Prevent Inaccuracies Caused By Dust And Debris Build-Up. Common Challenges And Solutions – **Misalignment**: If Threads Are Not Aligning Correctly, Check For Wear Or Slippage In The Half-Nut System And Recalibrate The Dial As Necessary. – **Tool Wear**: Ensure That Cutting Tools Are Sharp And Suitable For The Material You Are Threading. Replace Or Sharpen Tools As Needed To Maintain Precise Threading. Conclusion Mastering The Use Of A Metal Lathe Thread Cutting Dial Is Crucial For Precise And Efficient Thread Creation. By Understanding And Following These Guidelines, Machinists Can Enhance Their Craftsmanship And Achieve Consistent Results.

Understanding the Metal Lathe Thread Cutting Dial

Imagine building anything without precise measurements. Confusing, right? The metal lathe thread cutting dial makes threading easier and more accurate. Ever wonder how to cut threads like a pro? This tool helps you line up threads on a spinning lathe. It’s like having a trusty sidekick for every threading job. Did you know this tiny dial speeds up the process, saving you time? With it, crafting perfect threads becomes child’s play!The Basics of Thread Cutting Dials

Definition and purpose in metal lathes. Key components and their functions.Thread cutting dials are like the unsung heroes of metal lathes. They help spin up the magic of making threads without going wonky. The dial ‘tells’ the operator when to start cutting, ensuring that every thread lines up perfectly and not like spaghetti.

Now, these dials might seem like humble discs, but they pack some cool parts:

| Key Components | Functions |

|---|---|

| Dial Face | Displays numbered points to sync threads. |

| Engaging Lever | Connects the dial to the lead screw for threading action. |

A wise lathe operator once said, “With the right tools, precision is effortless.” This captures the essence of the thread cutting dial nicely. Want threads that hug your screws like a best friend? Trust the dial.

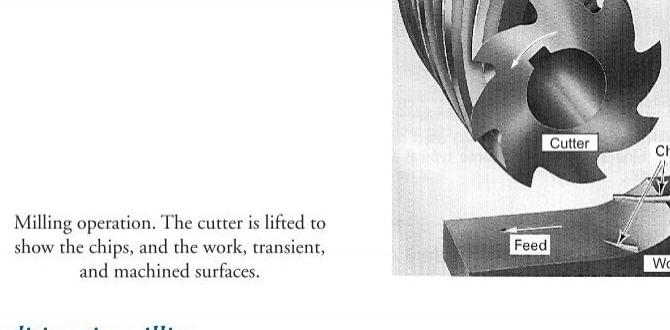

How Thread Cutting Dials Work

The mechanism of thread engagement. Importance of gear ratios in threading.Ever wondered how a metal lathe performs its magic trick with thread cutting? It’s all about the thread cutting dial. Essentially, this dial is like a map, directing the tool to engage the right thread at the right time. The secret sauce here is the gear ratios. Different gears mean different threads! If the gear ratios are off, you’ll end up with threads that are more ‘oops’ than ‘wow’. So, remember, the right gears play a big role in threading success.

Now, let’s break it down a little more with this handy table:

| Gear Ratio | Thread Type |

|---|---|

| 1:1 | Standard Thread |

| 1:2 | Fine Thread |

| 2:1 | Coarse Thread |

So next time you’re near a metal lathe, think of the gear ratio as the DJ setting the playlist hit. Without the right tunes, you can’t dance, and without the right gear ratio, the threads won’t groove together just right!

Types of Thread Cutting Dials

Different models based on lathe type. Advantages and disadvantages of each type.Thread cutting dials come in different forms. Each type works with specific lathes. Let’s explore them:

- **Manual Dials:** Best for simple lathes. They cost less but take time to use.

- **Electronic Dials:** Fit for advanced lathes. They offer accuracy but need power.

Consider your needs before picking. Manual ones need patience, while electronic choices offer precision but at higher costs. Which one would you choose?

What is a thread cutting dial used for?

A thread cutting dial helps line up threads on a metal lathe. It ensures cuts start at the same point. This saves time and improves accuracy. Would you like your work more precise?Selecting the Right Thread Cutting Dial

Factors to consider for specific lathes. Compatibility considerations.Picking the best thread cutting dial for a metal lathe can make you feel like a detective on a mission. Each lathe wants its own special dial. It’s like finding the perfect pair of socks. Lathes can get grumpy if their dial doesn’t fit. If you try to force them, it might result in a metal meltdown! Before getting a dial, check these:

| Factor | What to Check |

|---|---|

| Thread Type | Ensure the dial fits the thread style. |

| Size Fit | The dial size must match the lathe’s spindle. |

| Material | Durable material avoids dial disasters. |

| Brand Compatibility | Some brands are like cats and dogs—they just don’t mesh. |

Always check the manual of your specific lathe model. You may also consult old Mr. Google or ask your local workshop guru. A well-matched dial can save you from future headaches and keep your projects spinning smoothly! As they say, “Measure twice, cut once.” Here, it’s more like “Dial twice, panic never.”

Step-by-Step Guide to Using a Thread Cutting Dial

Preparation and setup procedures. Precise measurements and adjustments.Before becoming the master of threads, your first mission is to prepare and set up your metal lathe. Start by ensuring it is clean and safe. Think of it as getting dressed for a fancy party—you wouldn’t want to show up with spaghetti on your shirt! Next, take precise measurements. Use a ruler or calipers, making sure your workpiece fits just right.

Now, let’s talk about adjustments, where every tiny twist counts. It’s like setting your radio to the exact station, so you don’t get static. Adjust the cutting tools, check the thread depth, and align the thread cutting dial. Don’t forget to test it on a scrap piece first.

| Preparation Steps | Key Actions |

|---|---|

| Clean the Lathe | Remove dust, oil, and chips |

| Measure the Workpiece | Check diameter and fit |

| Adjust Tools | Set depth and alignment |

By following these steps, you’ll be threading like a pro in no time. Remember, patience and precision are your best buddies here! As the great machine said, “Measure twice, cut once!”

Troubleshooting Common Issues

Identifying and resolving alignment problems. Tips for preventing threading errors.Machines sometimes act like moody cats—especially metal lathes. If things aren’t cutting smoothly, it might be an alignment problem. To fix it, make sure the gears are in their proper place. This keeps the lathe aligned. A properly maintained machine decreases threading errors. A quick check now and then can save you a headache later. Prevent thread mishaps by keeping cutting tools sharp.

Need a quick guide? Check below!

| Problem | Solution |

|---|---|

| Misalignment | Adjust gears and check alignment regularly. |

| Threading Errors | Keep tools sharp and maintain the thread-cutting dial. |

Remember, “A stitch in time saves nine.” With proper maintenance, your lathe won’t turn into a naughty machine!

Maintenance and Care for Thread Cutting Dials

Routine cleaning and lubrication tips. Inspection practices to ensure longevity.Taking care of your thread cutting dial on a metal lathe can be easy and even fun! First, keep it clean. Just like how socks get lost in the laundry, dust likes to hide in tiny parts. Wipe it with a soft cloth and use a bit of oil once a week. Next, check for damaged teeth. A broken tooth on a dial is as unpleasant as a missing tooth on a teddy bear! Routine inspections ensure everything runs smoothly. Keep your dial happy, and it will serve you well.

| Maintenance Task | Frequency |

|---|---|

| Cleaning | Weekly |

| Lubrication | Weekly |

| Inspection | Monthly |

Proper maintenance increases the life of your equipment, much like brushing your teeth! Lubricate to prevent parts from grinding like an old door. And always inspect parts regularly to avoid wearing them out faster. Remember, a well-cared-for dial is a happy dial!

Enhancing Thread Cutting Efficiency

Best practices for consistent results. Tools and accessories to improve accuracy.Cutting threads on a metal lathe can be tricky. To get consistent results, follow these tips. Always check your tools. Make sure they are sharp and well-fit. It helps to use a thread cutting dial, which guides you to start the cut at the right time. Be patient and take care with details.

- Use a thread gauge to measure accuracy.

- Keep a good light on your workspace.

- Wear safety glasses.

These actions make thread cutting easier and more accurate.

### **What is a thread cutting dial used for?**A thread cutting dial helps align the lathe for starting the thread cut. It shows when to engage the lever for each pass. This ensures the tool starts at the right place each time. Proper use helps in achieving precise thread spacing, avoiding overlaps or gaps.

Conclusion

A metal lathe thread cutting dial helps you cut precise threads. It tracks the spindle’s rotations, ensuring even cuts. Understanding this tool improves your skills and projects. We encourage you to explore more about lathe operations. Practice using the thread cutting dial to become a more confident and skilled metalworker. Keep learning and experimenting!FAQs

How Does A Thread Cutting Dial Function On A Metal Lathe And What Role Does It Play In Ensuring Precision During Threading Operations?A thread cutting dial on a metal lathe helps line up the tool to cut threads accurately. Imagine it as a special clock that tells you when to start cutting. You wait for the pointer on the dial to reach the right number before you begin. This makes sure you cut clean, even threads every time. That’s how your toy screws can fit perfectly!

What Are Some Common Problems Encountered With Thread Cutting Dials On Metal Lathes, And How Can They Be Resolved?Thread cutting dials can have some problems. Sometimes they get jammed with tiny metal pieces called swarf. You can fix this by cleaning the dial with a brush and oil. Another problem is the dial not turning properly. You can solve this by making sure it’s attached tightly and adjusting it if needed.

How Do You Select The Correct Change Gears On A Metal Lathe For Thread Cutting Using A Thread Cutting Dial?To cut threads with a metal lathe, you first pick the right change gears. These gears decide how the lathe spins and cuts. Look at a chart on the lathe that shows which gears to use for your thread. After choosing, follow the chart, and set the gears in place, so it works right. Then, you can turn the lathe on and cut the threads you need!

Can You Describe The Process Of Calibrating A Metal Lathe Thread Cutting Dial To Ensure Accurate Threading?Sure! To get the thread cutting dial on a metal lathe just right, first, you need to make sure everything is clean and free of dirt. Then, line up the tool, which cuts the thread with the part that spins round and round, called the workpiece. We check the gears to make sure they match the threads we want to cut. Finally, as the lathe spins, we watch closely to ensure everything lines up and cuts smoothly. With practice, the threads will be perfect!

What Safety Precautions Should Be Taken When Using A Thread Cutting Dial On A Metal Lathe To Prevent Accidents Or Damage To The Workpiece?When using a thread cutting dial on a metal lathe, always wear safety goggles to protect your eyes. Keep your fingers and clothing away from the spinning parts to avoid getting hurt. Make sure the workpiece is secure so it doesn’t move around. Always double-check your settings before you start cutting.