Have you ever wondered how a metal lathe works? This amazing machine shapes metal into all sorts of objects. However, to make different parts, you need to change tools. This sounds simple, right? But there’s a right way to do it!

Performing a proper metal lathe tool change procedure ensures your project runs smoothly. Imagine trying to carve a statue but using the wrong chisel. It would not turn out well! Understanding how to change the tools correctly can save time and prevent mistakes.

Many people don’t realize that each tool has its job. By knowing the tool change steps, you can unlock the full power of your lathe. Want to make your projects easier and more fun? Let’s dive into the tool change process and learn the best practices!

Metal Lathe Tool Change Procedure: A Step-By-Step Guide

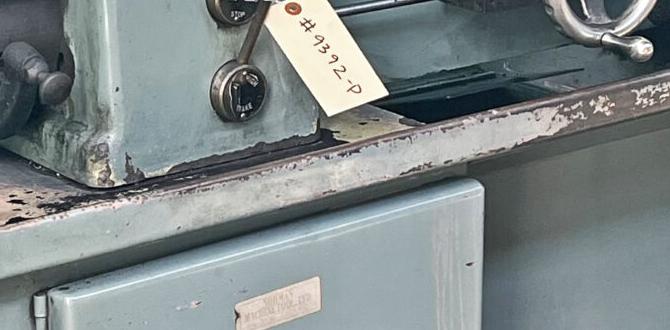

Metal Lathe Tool Change Procedure

Changing tools on a metal lathe may seem tricky, but it’s straightforward once you understand the steps. Begin by ensuring the lathe is off and safe. Next, use the tool post to remove the old tool without damaging the setup. Did you know that the right tool can significantly enhance your work? Once you’ve installed the new tool, double-check its alignment. Following these steps ensures smooth cutting and expert results every time.Safety Precautions

Personal protective equipment (PPE) requirements. Safety checks before starting the tool change.Before changing tools on a metal lathe, safety is key. Wearing proper personal protective equipment (PPE) is a must! This includes safety goggles to protect your eyes and gloves to keep your hands safe—unless you want to audition for a horror movie! Always check the machine before starting. Make sure to inspect for loose parts and ensure everything is in top shape. Trust me, it’s better to check twice than to fix once!

| PPE | Requirements |

|---|---|

| Safety Glasses | Protect your eyes from flying debris! |

| Gloves | Keep your hands safe, but avoid loose ends! |

| Ear Protection | Watch out for the loud noises; they’re not music! |

| Steel-Toe Boots | Protect your toes from getting squished! |

Preparation for Tool Change

Confirming the lathe settings and specifications. Gathering necessary tools and equipment.Before making a tool change, it’s wise to ensure everything is set correctly. Check the lathe settings and specifications. You don’t want to be surprised by a rogue screw! Next, gather all necessary tools and equipment. This includes wrenches, new tools, and safety gear. Having everything ready prevents last-minute scrambles that could leave you scratching your head like a confused chicken. Below is a quick checklist to help you prepare:

| Task | Status |

|---|---|

| Confirm lathe settings | ✅ |

| Gather tools | ✅ |

| Put on safety gear | ✅ |

Step-by-Step Tool Change Procedure

Detaching the current tool: methods and techniques. Securing the new tool: aligning and tightening methods.Changing a tool on a metal lathe is simple when you break it down. First, detach the current tool. You can do this by loosening the tool holder. Use a wrench or a special key to remove it safely. Next, grab the new tool. Make sure it fits properly. Align it correctly in the holder. Tighten the screws with the wrench until it is secure. This keeps the tool in place while you work.

What are some methods for detaching and securing tools?

Detach with a wrench and loosen all screws. Secure by aligning the new tool straight and tightening to prevent movement.

- Use the correct tools like a wrench.

- Align the tool properly in the holder.

- Tighten securely to avoid slips.

Adjusting Lathe Settings Post Tool Change

Calibrating tool height and centerline. Checking and adjusting tool offsets.After changing your tool, it’s super important to adjust the lathe settings. First, make sure to calibrate the tool height and centerline. This will help ensure everything lines up just right, and you won’t end up with a surprise that resembles a snail rather than a nice curve. Then, check and adjust the tool offsets. This keeps the cutting edge in the right spot. Here’s a quick reference:

| Adjustment Step | Action Required |

|---|---|

| Tool Height | Measure and adjust to match the workpiece centerline |

| Tool Offset | Check and update to ensure correct positioning |

Following these steps keeps your lathe running smoothly. A well-tuned machine is like a happy puppy – ready to perform tricks!

Troubleshooting Common Tool Change Issues

Identifying misalignments and faults. Solutions for tool binding and vibrations.Tool change mishaps can be annoying! Sometimes, the tools just don’t align right, leading to misfits and faults. Check if everything is snug and secure. If tools are binding, give them a gentle wiggle! This often helps them slide into place, like a dance partner that just needs a little coaxing. If there’s vibration, it could mean something is loose. Tighten those screws like they owe you money!

Here’s a quick guide to solving common issues:

| Issue | Solution |

|---|---|

| Misalignment | Check screws; adjust if needed |

| Tool Binding | Wiggle tool; ensure it’s clean |

| Vibration | Tighten screws; inspect for wear |

Remember, a well-aligned tool is a happy tool! Don’t let small issues spin you out of control.

Maintenance Tips for Longevity

Regular inspections and maintenance routines. Best practices for tool storage and handling.Keeping your metal lathe happy is like caring for a pet goldfish—pay attention, and it’ll last longer! Regular inspections are key. Check for any wear or tear, just like you check your shoes before a game. Make a weekly routine to keep everything running smoothly.

And let’s talk about storage. Tools are like a superhero team; they need everyone in their place to fight bad cuts. Store them in a cool, dry spot. Use a clean cloth to wipe them after use—just like washing your hands, but for tools!

| Tip | Description |

|---|---|

| Regular Inspections | Check for wear and tear weekly. |

| Tool Storage | Keep in a dry spot to avoid rust. |

| Cleaning | Wipe tools after use; it helps. |

Following these practices can save you time and money. Besides, a well-maintained lathe is like a good friend: it always delivers!

Advanced Tool Change Techniques

Multitool changers and automation. Utilizing tool presetters for efficiency.Tool changers make switching tools quick and simple. They can change multiple tools automatically, saving time. This advanced technique is especially useful in busy workshops. Another tool for efficiency is the tool presetter. It prepares tools before use, ensuring they’re ready for action. This helps reduce downtime and increases productivity. Here are some benefits:

- Faster tool changes

- Less human error

- Improved workflow efficiency

Using these methods can help your metal lathe work better.

What are multitool changers and automation?

Multitool changers allow machines to switch between different tools automatically. This speed boosts production and helps keep projects on track.

FAQs Regarding Metal Lathe Tool Changes

Common questions about procedures and best practices. Resources for further learning and support.Many wonder about the best ways to change tools on a metal lathe. One common question is, “How often should I change the tool?” The answer is simple: whenever it becomes dull or damaged. Another question is about safety. Remember to always wear goggles and gloves! For more tips, you might check out videos or guides online. The right resource can make your work easier. Here’s a quick reference table with common tools and their uses:

| Tool | Use |

|---|---|

| Cutting Tool | Shaping metal |

| Drill Bit | Making holes |

| Facing Tool | Flattening surfaces |

So, remember, keep your tools sharp and use the right one for the job. Then, you’ll be a metal lathe wizard in no time!

Conclusion

In conclusion, understanding the metal lathe tool change procedure is essential for safe and effective machining. Always follow the steps closely to avoid mistakes. Remember to wear safety gear and keep your workspace organized. You can practice these skills through hands-on experience or guides. Keep learning, and soon you’ll feel confident with tool changes!FAQs

What Are The Safety Precautions To Follow During A Tool Change On A Metal Lathe?When changing tools on a metal lathe, always turn off the machine first. Make sure to wear safety glasses to protect your eyes. Keep your hands away from moving parts to avoid getting hurt. Use the right tools for the change, so it’s safe and easy. Lastly, double-check that everything is tight and secure before starting again.

How Do You Properly Remove And Install Cutting Tools In A Metal Lathe?To remove a cutting tool from a metal lathe, first, turn off the machine and let it cool down. Next, use the right tool to loosen the screws or clamps holding the cutting tool in place. Carefully take the old tool out, making sure not to touch any sharp edges. To install a new cutting tool, slide it into the holder and tighten the screws securely. Make sure everything is tight before turning the machine back on.

What Types Of Tool Holders Are Commonly Used In Metal Lathes, And How Do They Differ?Metal lathes use different tool holders to hold cutting tools. The most common types are quick-change tool holders and standard tool holders. Quick-change tool holders let you swap tools fast, which saves time. Standard tool holders are more basic and take longer to change tools. Each type helps cut metal in different ways but fits in the lathe.

How Can You Ensure Accurate Alignment And Positioning Of Tools After A Change On A Metal Lathe?To make sure your tools are lined up right on a metal lathe, you should first turn off the machine. Then, check your tool holders to see if they are tight. Next, use a ruler or caliper to measure the tool’s position carefully. Adjust the tool until it matches the right measurements. Finally, do a quick test spin to check if everything works smoothly.

What Common Mistakes Should Be Avoided When Changing Tools On A Metal Lathe?When changing tools on a metal lathe, you should avoid rushing. Take your time to make sure everything is tight and safe. Always turn off the machine before you change the tools. Check that you have the right tool for the job before starting. Finally, keep your hands and clothes away from moving parts to stay safe.