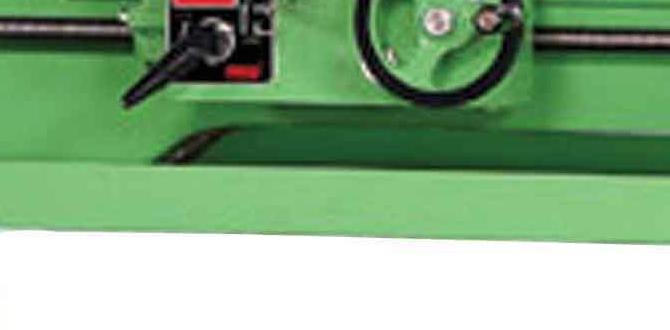

A midi wood lathe with a digital display offers incredible precision and ease of use, making it a genius essential tool for beginners and seasoned woodturners alike. It simplifies measurements for smoother operation and more accurate results, taking the guesswork out of your projects.

Hey there, fellow makers! Daniel Bates here, your guide from Lathe Hub. Ever stared at a piece of wood on your lathe and wished you could be absolutely sure about its dimensions? That little bit of uncertainty can be frustrating, especially when precision matters. It’s like trying to bake a cake without a measuring cup – you might get close, but perfection is harder to reach. Well, I’ve got some fantastic news for you. We’re diving into a tool that’s revolutionizing small-scale woodturning: the midi wood lathe with a digital display. It’s a game-changer, and by the end of this, you’ll see exactly why it might be the genius addition your workshop has been waiting for.

Why a Midi Wood Lathe? And What’s With That Digital Display?

So, what exactly is a midi wood lathe, and why should you care about the digital display part? Let’s break it down simply.

The “Midi” Advantage

A midi wood lathe is essentially a smaller, more compact version of a full-sized lathe. Think of it as the perfect sweet spot for many home workshops. They’re:

- Space-Saving: They don’t take up a huge amount of floor space, making them ideal for garages, basements, or even larger craft rooms.

- Versatile: Despite their size, they can handle a surprising range of projects, from decorative bowls and pens to smaller furniture components.

- Beginner-Friendly: Their smaller scale often means less intimidation and easier operation for those just starting out.

- Affordable: Generally, midi lathes are a more budget-friendly entry point into woodturning compared to their larger counterparts.

The Digital Display: Your New Best Friend

Now, let’s talk about that digital display. This is where the “genius” part really shines. Traditionally, measuring on a lathe involves stopping the machine and using calipers or rulers, which can be a bit fiddly and interrupt your workflow. A digital display, often built into the headstock or tailstock, shows you real-time measurements as you work.

Imagine this: you’re turning a spindle to a specific diameter. With a digital display, you can watch the numbers change as you carefully shave away wood with your chisel. You can set target dimensions and get immediate feedback, allowing you to stop precisely where you need to be. No more second-guessing or multiple measurements! This dramatically reduces errors and speeds up your turning process.

The Genius of Precision: How the Digital Display Works

The magic behind the digital display lies in its ability to accurately track the position of the tool rest or the tailstock quill. This is usually achieved through sensors that read a specialized scale or encoder. Here’s a simplified look:

- Encoder Technology: Many digital readouts (DROs) use optical or magnetic encoders. As a part of the lathe moves (like the tailstock quill extending or retracting for depth), the encoder detects this movement and sends signals to the display unit.

- Real-Time Feedback: The display unit then translates these signals into precise measurements, showing you the exact position in millimeters or inches.

- Presetting Capabilities: Some advanced digital displays even allow you to preset a desired measurement. The display will then count down or up, letting you know when you’ve reached your target.

This level of precision is incredibly valuable. For instance, when drilling a hole squarely into the end of a turning project, you can precisely control the depth of the tailstock quill. Similarly, when hollowing out a bowl, you can monitor the wall thickness with greater confidence.

Essential Features to Look For in a Midi Wood Lathe With Digital Display

When you’re ready to shop, here are some key features to keep an eye out for. Not all midi lathes with digital displays are created equal, so knowing what to prioritize will help you make a smart choice.

1. Digital Readout (DRO) Accuracy and Type

The most crucial element is the digital display itself. What kind of accuracy does it offer? Is it easy to read under workshop lighting? Some common features include:

- Accuracy Rating: Look for a display that’s accurate to at least 0.01 inches or 0.1 mm for most woodworking tasks.

- Display Size and Brightness: A larger, brighter display is easier to see at a glance, especially if you have dust in the air.

- Units: Ensure it can switch between inches and millimeters easily.

- Zeroing Function: The ability to zero out the display at any point is essential for relative measurements.

- Presetting (Optional but great): The ability to pre-set a specific dimension you want to reach.

2. Lathe Motor Power and Speed Control

Even with a great display, the lathe needs to be capable of handling your projects. Consider:

- Motor Horsepower (HP): For midi lathes, 3/4 HP to 1 HP is common and sufficient for most beginner to intermediate projects. More power means it can handle slightly larger or denser woods without bogging down.

- Variable Speed Control: This is a must-have. Being able to adjust the spindle speed on the fly is critical for safety and for achieving the best finish on different wood types and project sizes. Look for a wide speed range (e.g., from 250 RPM to 3500 RPM).

For more on motor power and speed, you can find helpful guidance from resources like Wood Magazine’s guide to choosing a wood lathe.

3. Swing and Distance Between Centers

These specs determine the maximum size of projects you can work on:

- Swing: This is the widest diameter of a workpiece the lathe can accommodate. A midi lathe typically has a swing of 10-14 inches.

- Distance Between Centers: This is the maximum length of a workpiece that can be mounted between the headstock and tailstock. Look for at least 16-18 inches for good versatility.

4. Bed Construction and Stability

A sturdy bed is essential for vibration-free turning and accuracy. Cast iron is generally preferred for its mass and damping qualities.

- Material: Look for a cast iron bed.

- Rigidity: The lathe should feel solid and not wobble, even at higher speeds.

5. Tool Rest and Tailstock Quill Features

These components are directly involved with your work. Ensure:

- Tool Rest: It should be easy to adjust in both height and angle, and lock securely in place. A comfortable grip on the adjustment knob is also a plus.

- Tailstock Quill: It should extend smoothly and lock firmly. The digital display is often integrated here or on the tailstock assembly.

Step-by-Step: Using Your Midi Wood Lathe With Digital Display

Alright, let’s get hands-on! Here’s a simple walkthrough to get you started with your new midi wood lathe and its fantastic digital display.

Step 1: Safety First – Always!

Before you even plug in the lathe, this is non-negotiable. Woodturning can be dangerous if safety precautions aren’t followed. Always wear:

- Safety Glasses or a Full Face Shield: Protect your eyes from flying debris.

- Dust Mask or Respirator: Wood dust can be harmful to your lungs.

- Hearing Protection: Lathes can be noisy.

- Appropriate Clothing: Avoid loose sleeves, jewelry, or anything that could catch on the rotating workpiece. Tie back long hair.

Familiarize yourself with the lathe’s emergency off switch. For more detailed safety guidelines, OSHA’s general industry safety and health regulations offer a foundational understanding of workplace safety, which is directly applicable to your workshop.

Step 2: Mounting Your Workpiece

Securely attach your piece of wood between the headstock (where the motor is) and the tailstock (the movable part). Ensure the wood is centered and the drive spur and live center are firmly engaged.

Tip: For larger or uneven blanks, consider using a faceplate or a chuck to ensure maximum security.

Step 3: Preparing for the First Turn

Turn on the lathe at its lowest speed setting. Slowly bring your tool rest close to the workpiece, leaving a small gap (about 1/8 inch or 3 mm). Lock the tool rest firmly in place.

Digital Display Check: If your DRO is integrated with the tool rest assembly, you might zero it out now if you plan to make a measurement relative to its current position. If it’s on the tailstock quill, ensure it’s set appropriately for your task.

Step 4: Rough Turning the Blank

Using a turning gouge (like a spindle gouge for beginners), gently start removing wood from the rotating blank. Begin at the headstock end and work your way towards the tailstock. Don’t try to hog off too much material at once, especially with softer woods.

Using the DRO: Let’s say you want to turn a spindle down to a specific diameter. You’ll gradually turn the wood, making light passes with your tool. Watch the digital display as the diameter decreases. You can set a target diameter if your DRO has that feature, or simply keep an eye on the numbers. Aim to get close to your target, then switch to a scraper or different tool for final smoothing.

Step 5: Shaping and Refining (Where the DRO Shines!)

This is where the digital display becomes incredibly useful:

- Turning to Diameter: As you approach your desired diameter, make very light passes. The DRO shows you exactly how far you are from your goal. If you need a section to be precisely 1 inch in diameter, you can turn until the display reads 1.000 inches (or 25.4 mm). This eliminates the need for constant caliper checks.

- Drilling Depth with the Tailstock: If you’re drilling a hole (e.g., for a pen blank or decorative element), you can extend the tailstock quill using its DRO. Set your desired depth, and stop precisely when the display indicates you’ve reached it. This ensures consistency and prevents over-drilling.

- Replicating Features: If you’re making multiple identical parts, the DRO allows you to precisely replicate dimensions from one to the next. This is invaluable for sets of items or components that need to mate together.

Step 6: Sanding and Finishing

Once the shaping is complete, you’ll typically sand the piece while it’s still on the lathe. Gradually increase sandpaper grit for a smooth finish. Clean off dust before applying any finishes.

Step 7: Dismounting and Cleanup

Turn off the lathe. Once the workpiece has completely stopped spinning, you can remove it. Clean your lathe, chisels, and the surrounding area. Always put your tools away safely.

Midi Wood Lathe With Digital Display: Pros and Cons

Like any tool, there are advantages and disadvantages to consider. For a beginner, the pros often significantly outweigh the cons.

Pros:

- Enhanced Accuracy: The primary benefit. Reduces errors and allows for precise replication of dimensions.

- Improved Workflow: Less time spent measuring, more time turning. Keeps you in the moment with your project.

- Reduced Guesswork: Takes the anxiety out of achieving specific sizes.

- Great for Learning: Helps beginners understand dimensions and tolerances more intuitively.

- Useful for Repetitive Tasks: Ideal for projects requiring multiple identical components (e.g., table legs, pen barrels).

- Often More Affordable than larger DRO-equipped lathes: Provides high-tech benefits without the full-size price tag.

Cons:

- Initial Cost Premium: Lathes with built-in digital displays are typically more expensive than basic models.

- Potential for Damage: The digital display components can be sensitive to dust and impact. Proper care is needed.

- Reliance on Power: The display needs power, usually from batteries or a small AC adapter. If the power source fails, the DRO stops working.

- Not Always Essential for Artistic Turning: For purely freehand artistic pieces where exact dimensions aren’t critical, a DRO might be overkill.

Comparison: Digital Display vs. Traditional Measurement

Let’s look at how using a digital display stacks up against traditional methods.

| Feature | Midi Wood Lathe With Digital Display | Traditional Midi Wood Lathe (No Digital Display) |

|---|---|---|

| Measurement During Turning | Real-time, continuous reading shown on display. | Requires stopping the lathe to use calipers, rules, or tapes. |

| Accuracy Achievement | Easier to achieve exact target dimensions consistently. | Relies more on user skill and feel, with potential for minor variations. |

| Workflow Efficiency | Faster, as measuring is integrated into the turning process. | Slower due to the need to stop and measure. |

| Learning Curve (for precision) | More intuitive for understanding and achieving precise sizes. | Requires learning to use measuring tools effectively and developing good “turning feel. |

| Cost | Generally higher initial investment. | Lower initial investment. |

| Complexity & Maintenance | Electronic components may require care against dust/impact. | Simpler mechanical components. |

Projects Perfect for Your New Midi Lathe

With the precision offered by a digital display, you can tackle a variety of projects with confidence. Here are a few ideas:

- Pen Turning: Achieving consistent barrel diameters and precise fitting for pen kits is much easier.

- Spindles: For furniture projects, craft items, or even decorative pieces, turning identical spindles is a breeze.

- Bowl Turning: While freehand bowls are an art, the DRO can help you achieve consistent wall thicknesses or set specific exterior diameters.

- Hollowing Cylinders: For items like candle holders or small vases, precisely controlling the internal and external dimensions is simplified.

- Small Toy Parts: Turning dowels, wheels, or other uniform components for wooden toys.

Maintaining Your Midi Wood Lathe and its Digital Display

To ensure your lathe and its digital display serve you well for years to come, a little regular maintenance goes a long way. This is crucial for longevity and continued accuracy.

- Dust Management: This is the biggest enemy of electronic components. Keep your lathe and the DRO sensors clean. A soft brush and compressed air can be very effective. Avoid spraying cleaners directly onto the display or sensors.

- Lubrication: Follow the manufacturer’s recommendations for lubricating bed ways, tailstock threads, and any moving parts.

- Checking Alignment: Periodically check that the headstock and tailstock are properly aligned. For most midi lathes, this involves ensuring the tailstock can traverse to form a perfect circle with the headstock spur.

- Sensor Cleaning: If you notice inconsistent readings, gently clean the optical or magnetic scales of the DRO. Consult your lathe’s manual for specific instructions.

- Battery Replacement: If your DRO is battery-powered, keep an eye on battery life. Replacing them before they die unexpectedly means the display won’t cut out mid-project.

For detailed maintenance advice, always refer to your specific lathe’s user manual. Manufacturers like Sherline and Proxxon, known for their precision benchtop machinery, often provide excellent downloadable manuals online.

What to Expect Next: Expanding Your Skills

Once you’re comfortable with basic turning and leveraging your digital display for precision, the world of woodturning opens up even further. You might consider:

- Different Turning Tools: Exploring bowl gouges, skew chisels, and scrapers for more complex shapes.

- Advanced Techniques: Learning about chuck mounting for coring bowls, turning segmented wood, or creating intricate joinery.

- Finishing Techniques: Experimenting with oils, waxes, lacquers, and other finishes to enhance the beauty of your work.