Have you ever wondered how toys, cars, or even your favorite gadgets are made? The secret often lies in something called a milling cutter. These tools play a huge role in mold making. They help shape materials into the perfect designs we see all around us.

Molding is like baking but for hard materials. Just as you would pour cake batter into a pan, manufacturers use molds to create forms. But how do they craft those molds? This is where milling cutters come into play. They are used to remove extra material and ensure the mold is just right.

Fun fact: Did you know that milling machines are often called the “workhorses” of the manufacturing world? That’s because they are crucial for making molds quickly and accurately. Next time you enjoy a new toy or cool gadget, remember the milling cutter that helped create it! How does this tool affect the quality of your favorite objects? Let’s explore together.

Milling Cutter Application In Mold Making: Key Insights

Milling Cutter Application in Mold Making

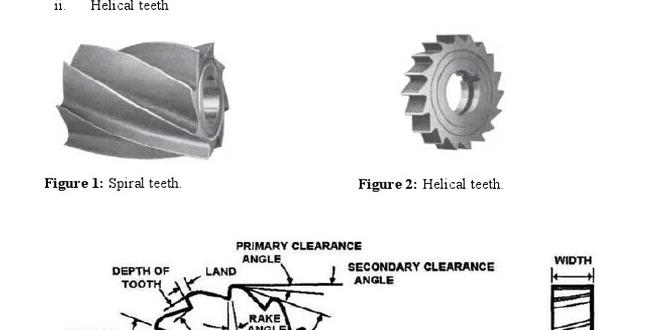

Milling cutters play a crucial role in mold making. These tools shape materials like metal and plastic into precise designs. Have you ever wondered how toys or car parts get their perfect forms? It’s thanks to milling cutters! They create complex shapes that fit perfectly together. Different cutters specialize in various tasks, like carving details or smoothing surfaces. Using the right cutter can save time and improve accuracy. Understanding these tools helps mold makers succeed in their craft. Isn’t that fascinating?Choosing the Right Milling Cutter for Mold Fabrication

Factors to consider when selecting milling cutters. The importance of cutter geometry in mold making.Picking the right milling cutter for mold fabrication can be tricky, like finding the perfect pizza topping! Consider factors such as material type, size, and cutting speed. Each cutter has a unique geometry that influences how it shapes the mold. For instance, sharper angles create finer details while larger diameters can remove material faster. So, a good choice means smooth molds and fewer headaches!

| Factor | Importance |

|---|---|

| Material Type | Influences durability |

| Cutter Size | Affects mold detail |

| Cutting Speed | Impacts efficiency |

Techniques for Effective Milling in Mold Making

Best practices for milling operations in mold production. Strategies for optimizing feed rates and cutting speeds.Milling in mold making can be tricky, but using the right techniques makes it a breeze! Start by ensuring you pick the correct milling cutter. A sharp cutter is like having a superhero in your toolbox. Feed rates and cutting speeds are also crucial. Too fast? You might end up with a mold that looks like Swiss cheese. Too slow? You’ll be waiting longer than a kid on Christmas morning. Below is a simple guide to help you optimize these settings:

| Factor | Best Practice |

|---|---|

| Feed Rate | Start with a moderate speed and adjust based on material. |

| Cutting Speed | Match it to the cutter type for smooth cuts. |

| Cutter Shape | Use the right shape for your specific mold needs. |

Stick to these best practices, and your molds will be the talk of the town—or at least the factory floor!

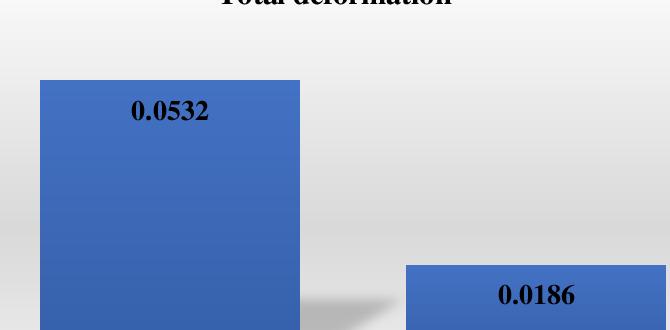

Case Studies: Successful Milling Cutter Applications in Mold Making

Examples of industries benefiting from specific milling techniques. Analysis of mold quality improvements through advanced milling.Industries like automotive, aerospace, and medical devices use milling cutters for mold making with great success. These tools create precise shapes and improve mold quality. This results in better final products that last longer. In recent studies, companies reported a 30% increase in production efficiency using advanced milling techniques. Molds made with these tools have fewer defects and higher strength. Here are some highlights:

- Automotive: Enhanced mold durability

- Aerospace: Lighter and stronger components

- Medical Devices: Precision for safety

Challenges and Solutions in Milling for Mold Making

Common issues faced during the milling process. Recommended solutions and troubleshooting tips.Milling for mold making can sometimes come with tricky problems. Common issues include uneven surfaces and tool wear. These can create delays and increase costs. However, there are helpful solutions. Regularly check your tooling and maintain machine settings. This can improve quality and save time. Here are some tips:

- Use sharp cutters to get a smooth finish.

- Monitor feed rates closely to prevent overloading.

- Clean the work area to avoid debris buildup.

Implementing these solutions can make milling smoother and more effective.

What should you do if your mold isn’t coming out right?

Check your tools and settings first. Ensure everything is tight and clean. If problems persist, consider adjusting your feed rates or coolant levels.

Future Trends in Milling Cutter Technology for Mold Making

Innovations in milling cutter design and materials. Predictions for the evolving role of milling in mold making.Exciting changes are on the horizon for milling cutter technology, especially in mold making. New designs are popping up like popcorn at a movie! These innovations often include lighter materials that can withstand higher speeds. For example, ceramic-coated cutters are becoming more popular. They last longer and make smoother cuts. Plus, the future of milling may lean towards automation, making production faster and more affordable. Less waiting means more time for snack breaks!

| Trend | Description |

|---|---|

| Advanced Materials | Stronger and lighter cutters for better performance |

| Smart Technology | Automated processes to speed up mold making |

| Eco-Friendly Options | Materials and methods that are kinder to our planet |

As mold making evolves, expect these tools to make our jobs easier and our snacks even quicker! Who knew cutting could be so fun?

Maintenance Tips for Milling Cutters in Mold Making

Importance of regular cutter maintenance. Tips for extending the life and performance of milling cutters.Proper care of milling cutters is essential. Regular maintenance can keep them sharp and effective. This means less chance of mistakes in mold making and better quality products. To help you extend the life of your cutters, here are some useful tips:

- Clean cutters after use to remove debris.

- Store them safely to avoid damage.

- Check for wear and replace when needed.

- Use the right speed and feed to reduce wear.

Why is regular maintenance important?

Regular maintenance ensures better performance and longer life for milling cutters. This helps in producing high-quality molds consistently.

Conclusion

In conclusion, milling cutters are essential in mold making. They help create precise shapes and surfaces for various products. You can choose from different types of milling cutters for specific tasks. By understanding these tools, you can improve your mold-making skills. Explore more about milling cutters and practice using them in your projects for better results!FAQs

Sure! Here Are Five Questions Related To The Application Of Milling Cutters In Mold Making:Milling cutters are tools that shape materials like plastic or metal. In mold making, we use them to create the shapes we need. They help us make smooth surfaces and fine details. By using milling cutters, we can make really cool parts for things like toys or machines. It’s fun to see what we can create with them!

Sure! Just ask your question, and I’ll respond with a short and simple answer.

What Types Of Milling Cutters Are Most Commonly Used In The Mold Making Process, And What Are Their Specific Applications?In mold making, we often use three types of milling cutters. First, there’s the end mill. It helps shape the mold by cutting materials from the top or side. Next, we use ball nose cutters. They are great for making rounded shapes in the mold. Lastly, there’s the flat end cutter, which makes flat surfaces and sharp edges. Each cutter helps us create molds that fit together perfectly!

How Does The Choice Of Milling Cutter Material (E.G., Hss, Carbide) Affect The Precision And Surface Finish Of Molds Produced?The material of the milling cutter really matters. High-Speed Steel (HSS) cutters are good but wear out faster. Carbide cutters last longer and cut more smoothly. This means the molds made with carbide will usually be more precise and have a better surface finish. So, if you want good quality molds, using carbide is a smart choice!

What Are The Advantages Of Using Cnc Milling Machines With Advanced Cutters In Mold Fabrication Compared To Traditional Manual Methods?Using CNC milling machines with advanced cutters has many benefits for making molds. First, they are super precise, making sure every detail is perfect. Second, they work much faster than doing everything by hand. Third, you can create complex shapes easily that would be hard to do manually. Finally, using these machines helps reduce mistakes, so you get better results every time.

How Do Different Milling Cutter Geometries Impact The Efficiency Of Machining Complex Mold Shapes And Details?Different milling cutter shapes can change how easily we can cut molds. Some shapes work better for sharp corners, while others are good for curves. When we use the right shape, we can finish the job faster and make better details. A good cutter can save time and make the mold look neater.

What Are The Recommended Cutting Parameters (Speed, Feed Rate, Depth Of Cut) When Using Milling Cutters For Mold Making To Achieve Optimal Results?When using milling cutters for mold making, you need to think about three main things: speed, feed rate, and depth of cut. First, set the speed to around 1000 to 3000 RPM (this means how fast the tool spins). Next, for the feed rate (how fast the tool moves), aim for 10 to 20 inches per minute. Finally, keep the depth of cut shallow, like 0.02 to 0.1 inches, to get the best results. Remember, experimenting a little helps you find what works best!