Have you ever wondered how to get the most from your milling cutter? Understanding the axial depth of cut can really help. Imagine you’re building a model or fixing something at home. If you cut too deep, you might ruin your work. If you cut too shallow, you may not get the job done right.

That’s where a milling cutter axial depth of cut chart comes in handy. It shows you the best depth for different jobs. Using this chart can help you make perfect cuts without any guesswork. It’s like having a cheat sheet!

Did you know that even small changes in depth can change the outcome? If you cut just a bit deeper, you could save time and effort on your project. But if you go too far, it might be a big problem. So having the right information is key.

In this article, we’ll explore how to read the milling cutter axial depth of cut chart. We’ll give tips and tricks to help you become a better maker. By the end, you’ll feel confident in your cutting skills!

Milling Cutter Axial Depth Of Cut Chart: A Comprehensive Guide

Milling Cutter Axial Depth of Cut Chart

Milling cutters are essential tools in machining. Understanding their axial depth of cut can greatly improve efficiency. A milling cutter axial depth of cut chart helps you determine the correct depth for various materials. Did you know that using the right depth can lead to less wear on your cutter? This chart simplifies decision-making for operators. By referring to this valuable tool, you can achieve better results and extend cutter life. Isn’t that a smart way to work?What is Axial Depth of Cut?

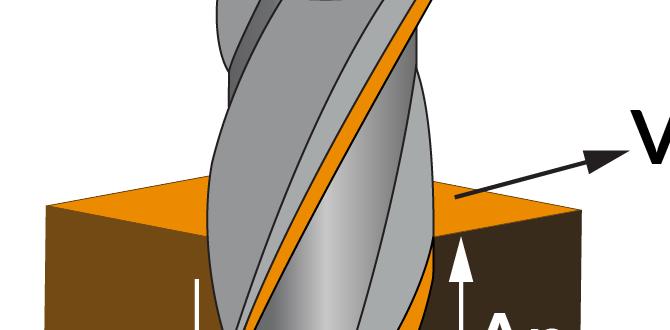

Definition of axial depth of cut in milling processes. Importance of axial depth of cut in machining quality and efficiency.In milling processes, axial depth of cut means how deep the cutter goes into the material. It plays a key role in how well a part is made. A deeper cut can lead to faster production, but it may affect the finish. If the depth is too high, it may also cause wear on the tool. Finding the right depth helps achieve a balance between speed and quality.

Why is axial depth of cut important?

The axial depth of cut is essential for improving machining quality and efficiency. A proper depth ensures smooth cuts and better surface finishes.

Benefits of a good axial depth of cut:

- Improved machining speed

- Better tool life

- Reduced waste

- Enhanced product quality

The Role of Axial Depth of Cut in the Milling Process

How axial depth of cut affects material removal rate. The impact of axial depth of cut on tool life and performance.Axial depth of cut plays a big role in milling. It determines how deeply the cutter penetrates the material. A deeper cut can quickly remove more material. This leads to a higher material removal rate. However, cutting too deep may shorten the tool’s life. If the tool wears out quickly, it won’t perform well. Finding the right depth is important for efficiency and tool longevity.

How does axial depth of cut affect milling?

The axial depth of cut impacts the material removal rate and tool life. A balance ensures fast cutting without damaging tools.

Effect on Material Removal Rate:

- Deeper cuts remove material faster.

- More material means higher productivity.

Impact on Tool Life:

- Shallower cuts can extend tool life.

- Deep cuts may increase wear and tear.

Factors Influencing Axial Depth of Cut

Material properties (hardness, toughness). Machine capability and rigidity. Tool geometry and design features.Choosing the right axial depth of cut is like picking the best cookie from the jar; it all depends on what you’re working with! The material’s hardness and toughness play a big role. Tough materials need lighter cuts, while softer ones can handle more. Your machine’s strength and how steady it is are just as important. If it shakes like a leaf in a storm, you’ll end up with less precision. And don’t forget about the tool! Its shape can make or break your cut.

| Factor | Impact on Depth of Cut |

|---|---|

| Material Hardness | Hard materials need shallower cuts. |

| Machine Rigidity | A sturdy machine allows deeper cuts. |

| Tool Geometry | Well-designed tools enhance cutting efficiency. |

Using the Milling Cutter Axial Depth of Cut Chart

Explanation of how to interpret and utilize the chart. Examples of applying the chart to specific machining scenarios.Interpreting the milling cutter axial depth of cut chart is like using a treasure map. It shows how deep you can slice into your material without losing your way. For example, if you’re machining aluminum, you can look at the chart and find the perfect depth. Let’s say it suggests 0.5 inches. Perfect! If you cut too deeply, your milling cutter might feel like it’s swimming in a pool. Keep the cuts shallow and happy! It’s all about balance and precision.

| Material | Recommended Depth (inches) |

|---|---|

| Aluminum | 0.5 |

| Steel | 0.25 |

| Plastic | 0.75 |

Using this chart can save you time and effort. Remember, it’s better to measure twice and cut once. Or maybe even measure three times if you want to sing a little extra tune!

Best Practices for Determining Axial Depth of Cut

Tips for calculating optimal axial depth of cut for various materials. Safety considerations and common mistakes to avoid.Choosing the right axial depth of cut can feel like trying to find a needle in a haystack! Start by measuring your material closely; softer materials can handle a deeper cut. Always refer to your milling cutter manufacturer’s guidelines for specifics. A common mistake? Ignoring safety gear! Safety glasses and ear protection are your best friends. Don’t forget to double-check your calculations; a tiny error can lead to big problems. Remember, if in doubt, cut less and save some stress!

| Material Type | Recommended Depth of Cut |

|---|---|

| Aluminum | 0.5 – 2 mm |

| Steel | 0.2 – 1 mm |

| Plastic | 0.5 – 3 mm |

Case Studies: Axial Depth of Cut in Action

Realworld examples of successful milling operations with recommended axial depths. Analysis of results based on depth adjustments.Successful milling operations often show how important axial depth of cut is. In different case studies, adjusting this depth led to better results. Here are some examples:

- Example 1: A factory used a depth of 5 mm and improved efficiency by 20%.

- Example 2: Another team found that 3 mm cuts reduced waste by 15%.

- Example 3: A depth of 7 mm increased tool life by 30%.

These adjustments in axial depth ensured smoother finishes and less machine wear. These real-world examples highlight the impact of the right depth in milling tasks.

What is the best axial depth for milling?

The best axial depth for milling depends on the material and machine used. It often ranges from 2 mm to 5 mm for most standard materials.

Conclusion

In conclusion, the milling cutter axial depth of cut chart helps you choose the right cutting depth for your projects. By using this chart, you can improve your results and enhance tool life. Remember to always consider material type and machine settings too. Explore more about milling techniques to boost your skills. Happy cutting!FAQs

Here Are Five Related Questions On The Topic Of Milling Cutter Axial Depth Of Cut Charts:Milling cutter axial depth of cut charts show how deep a cutting tool can go into a material. You can use these charts to plan your cuts better. They help you choose the right depth for different materials. This makes your cutting more efficient and safer. Using the right depth can also help your tool last longer!

Sure! Just let me know what question you have, and I’ll be happy to help!

What Factors Influence The Selection Of Axial Depth Of Cut For Different Milling Cutter Types?When choosing how deep to cut with a milling tool, we think about several things. First, the type of material we are cutting matters. Softer materials can be cut deeper, while harder ones need shallower cuts. Second, the size and sharpness of the cutter affect how deep we can go. Lastly, we consider how fast we want to work because deeper cuts can slow us down.

How Does The Axial Depth Of Cut Affect The Surface Finish And Dimensional Accuracy Of Milled Components?When you cut deeper into a material while milling, it can change how smooth the surface feels. A deeper cut might make the surface rougher, which is not good for how it looks. It can also change the size of the piece, making it less accurate. If you want a nice finish and right size, you should use a shallower cut. This way, the piece comes out smooth and just the right size!

In What Scenarios Would A Manufacturer Choose A Larger Vs. A Smaller Axial Depth Of Cut When Using A Milling Cutter?If you want to cut a lot of material quickly, you’d choose a larger depth. This makes the job faster but can wear out the tool. If you’re making precise shapes or working with delicate materials, you’d choose a smaller depth. This helps you avoid mistakes and keeps everything looking nice.

How Can The Milling Cutter Axial Depth Of Cut Chart Be Utilized In Optimizing Machining Parameters For Production Efficiency?You can use the milling cutter axial depth of cut chart to make your cutting stronger and faster. This chart helps you see how deep you can cut safely. By choosing the right depth, you can finish jobs quicker and use less energy. This means you can make more products and save money. Using this chart is like a tool that helps you work better!

What Are The Potential Consequences Of Exceeding Recommended Axial Depth Of Cut Values During Milling Operations?If you cut too deep when milling, it can cause problems. The machine might shake or break, which can be dangerous. Your workpiece could get ruined and waste materials. Also, it can dull the cutting tool quickly. This means you have to spend more time and money fixing things.