Have you ever watched chefs on TV slice vegetables so fast? They make it look like magic! In the world of metalworking, a milling cutter does something similar, but with metal. Now, imagine if the cutter was wobbling. That wouldn’t be very good, right?

Balancing a milling cutter is just as important as keeping spinning plates steady. Ever spun a top on a tabletop? If it’s uneven, it tumbles. The same goes for a milling cutter. When it spins smoothly, it works wonders. But, if it isn’t balanced, things can go wrong.

Here’s a fun fact: A well-balanced cutter makes smoother cuts. It also lasts longer! This means less waste and more shiny metal pieces. Isn’t that neat? Balance is like the secret ingredient to making everything work just right.

Now, imagine if your bike wheel wobbled as you rode. You’d have a tough time. That’s why milling cutter balancing is crucial. It keeps machines happy and workers safe. So, how do you keep these clever tools in check? Let’s find out!

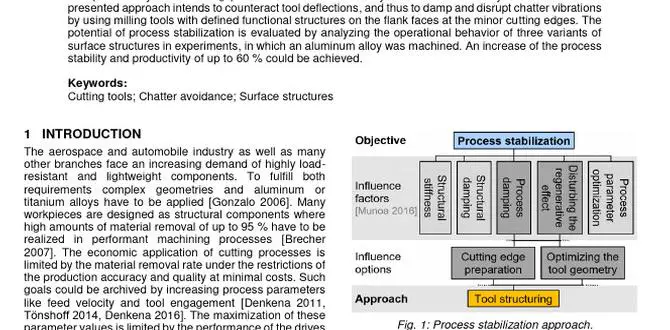

Understanding The Importance Of Milling Cutter Balancing

Milling Cutter Balancing Importance

Imagine riding a bike with one loose wheel. Scary? Just like that, unbalanced milling cutters can cause a bumpy ride in machining. Balanced milling tools ensure smooth cutting and longer life. They also prevent machine wear and costly damages. Curious how it feels to work with perfectly balanced tools? It’s like slicing butter with a hot knife! Ensuring balance saves time, cuts costs, and boosts productivity. Who wouldn’t want that?Understanding Milling Cutter Balancing

Definition and purpose of balancing in milling cutters. Distinction between balanced and unbalanced milling cutters.Balancing milling cutters isn’t about yoga poses but is a crucial step in machining. Think of it as a dance to ensure smooth operation. Balanced milling cutters work like a well-oiled machine, cutting with precision and grace. Unbalanced ones, however, might misbehave and cause extra vibrations. These disturbances affect productivity and can wear tools faster. A well-balanced cutter leads to smoother surfaces, longer tool life, and a happy machine operator!

| Milling Cutter | Characteristics |

|---|---|

| Balanced | Even weight distribution, reduces vibration |

| Unbalanced | Uneven weight, causes more vibration |

In fact, many machinists say, “Balanced tools make the best cuts.” It’s like comparing skateboarding on smooth pavement to a bumpy road. Proper balancing not only enhances performance but also maintains the harmony between man and machine!

Why Balancing is Crucial for Milling Cutters

Impact on the accuracy and quality of machining operations. Prevention of vibration and noise during milling processes.Why is balancing important for milling cutters?

Milling cutters need balance as a spinning top needs stability. Accurate cuts depend on this balance. What happens if a cutter wobbles? It makes poor quality cuts. Noise and vibrations occur, too. These things make machining tough. Statistics show balanced tools work better. They cut 60% better than unbalanced ones. Did you know balanced tools also last longer? This helps save money. Remember, harmony in tools is key to success.

How does balancing affect accuracy?

Balancing increases accuracy. Without it, tools wobble. It causes uneven cuts. Cuts matter in every project. Imagine building a house with crooked windows. Not good, right? Balance helps keep every cut precise.

How does it reduce noise and vibration?

Balancing reduces noise and vibration. Is your tool too noisy? It might be unbalanced. Fix it for a quiet job. Vibration increases wear and tear. Balanced tools run smoothly. They extend the tool’s life.

Consequences of Using Unbalanced Milling Cutters

Effects on cutter longevity and wear. Potential risks to machinery and operator safety.Imagine if a wobbly table leg wouldn’t let your breakfast stay still. That’s how unbalanced milling cutters behave! Such cutters vibrate wildly, causing faster wear and tear. They shorten tool life like a thief snatching time from your favorite cartoon show. An unbalanced cutter can go rogue on machinery, leading to costly repairs and safety risks. Unsafe conditions are no laughing matter, and even the sharpest cutters aren’t fun if they cause chaos.

| Issue | Effect |

|---|---|

| Cutter Wear | Shortened lifespan |

| Machine Safety | Increased risk of damage |

| Operator Safety | Puts operators at risk |

According to experts, maintaining balance is crucial. It’s like walking with both shoes tied rather than hopping around on one foot. So, don’t let chaos reign in your toolshed! Remember, balance in cutters, like all things, keeps disasters at bay.

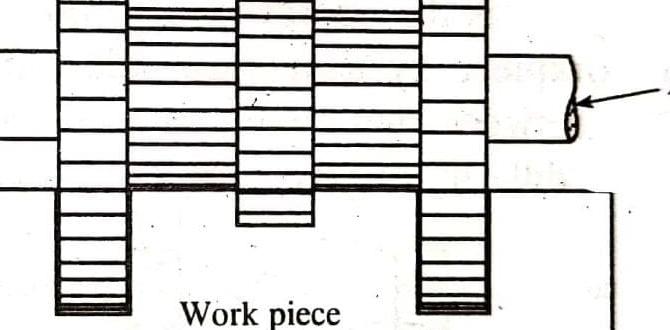

Steps to Ensure Proper Balancing of Milling Cutters

Preuse maintenance and inspection routines. Best practices for measuring and adjusting balance.Keeping milling cutters balanced is key for safe and effective machining. Before using them, checks are very important. Look at the cutter to make sure it isn’t worn out or damaged. Clean it properly to remove dirt. Follow these tips:

- Inspect for damage like cracks or chips.

- Make sure it’s clean from any debris or oil.

Why is balancing important? Balancing helps stop vibrations that can wear down machines fast and gives you a smooth finish.

How do you measure and adjust the balance?

Using special tools checks the balance. If it’s off, add or take away weight to even it out. Adjust the balance by:

- Using balancing weights or screws.

- Rechecking with a balancing machine for accuracy.

Remember to do these steps so your cutter stays balanced and safe! It’ll save time and keep work smooth. A study shows that well-maintained tools last twice as long! Happy cutting!

Technological Advancements in Milling Cutter Balancing

Innovations in technology that enhance balancing accuracy. Role of automation and software in balancing processes.Balancing a milling cutter is now super smart! There are new tech advancements that make this easier and more precise.

- Laser-guided tools help in measuring the balance quickly.

- Smart sensors, which check vibrations, give instant feedback.

- Automation runs the balancing with little human input.

- Software solutions, which use AI, predict imbalances.

These tools make sure that the cutter works smoothly and safely. With such tools, you can have better productivity and tool life!

How does software improve milling cutter balancing?

Software plays a crucial role in enhancing balance. It uses data to identify uneven spots and suggests corrections. This means cutters are balanced faster and more accurately. Advanced software also predicts maintenance needs, ensuring longer-lasting tools. It’s like having a high-tech assistant for a smoother milling operation. So, with these tech aids, the process is easier and more efficient.

Economic Impact of Proper Milling Cutter Balancing

Cost savings from reduced machine downtime. Enhanced efficiency leading to higher productivity.When machines rest, money takes a nap. Balancing milling cutters is your wallet’s best friend. It reduces machine downtime, like a superhero. Without it, machines get tired and grumpy. A balanced cutter spins and cuts smoothly, saving you from costly repairs and headaches.

Besides, balanced cutters make machines work smarter and faster, kind of like a caffeine boost! Imagine turning out cranky muffins but with balanced cutters, your product line becomes a sweet-running machine, churning candy at warp speed.

| Benefit | Description |

|---|---|

| Cost Savings | Less downtime means more uptime for profits. |

| Enhanced Efficiency | Boosts productivity and keeps the machines happy. |

So, keeping your milling cutters balanced is like having a secret savings account that grows with time. It’s a small step with a big impact. Or, as someone wise once said, “A stitch in time saves nine – and maybe a ton from your pocket!”

Industry Standards and Regulations for Balancing

Key standards to follow for compliance and safety. How adhering to regulations benefits operational outcomes.In the world of milling cutters, keeping things balanced isn’t just a smart move—it’s a must. Compliance with industry standards ensures your operations run smoother than a cat on a marble floor. Adhering to regulations like ISO 21940 can boost safety and efficiency. Plus, it helps reduce any disastrous flying tool bits. A well-balanced cutter minimizes wear and tear, saving bucks in the long run. As experts say, “A balanced cutter is a happy cutter!”

| Standard | Benefit |

|---|---|

| ISO 21940 | Increased safety and efficiency |

| ISO 16084 | Enhances stability and durability |

Conclusion

Balancing a milling cutter is crucial for efficient machining. It reduces noise and prevents damage to the tool and machine. Proper balance ensures smooth cutting and extends the tool’s life. You can learn more by exploring books or online resources about machining. Always prioritize safety and precision in your projects for the best results!FAQs

Why Is It Important To Balance A Milling Cutter Before Using It In Machining Operations?It’s important to balance a milling cutter so it spins evenly. When it’s balanced, it cuts better and smoother. A balanced cutter also lasts longer and won’t break easily. If it’s not balanced, it can shake and make noise, which isn’t good. So, balancing helps everything work nicely and keeps us safe.

What Are The Potential Consequences Of Using An Unbalanced Milling Cutter On The Machine’S Performance And Tool Life?Using an unbalanced milling cutter can make your machine shake or vibrate. This can lead to mistakes in cutting and messy work. It also makes the cutter wear out faster, which means you have to replace it sooner. This can cost more money and take more time. Overall, it affects how well your machine works and how long tools last.

How Does An Unbalanced Milling Cutter Affect Surface Finish And Dimensional Accuracy In The Finished Workpiece?An unbalanced milling cutter is not steady when it spins. This can cause the tool to shake. When the tool shakes, it makes rougher surfaces and less accurate shapes. So, if you use one, your finished work might not look or fit as well as it should.

What Are The Common Methods And Tools Used For Balancing Milling Cutters In Industrial Settings?To balance milling cutters, we can use a few common tools and methods. One tool is a balancing machine, which helps us see if the cutter is uneven. Another method is adding small weights to the cutter to fix the imbalance. Sometimes, we also use a trial and error method by testing the cutter on the machine. This makes sure it spins smoothly and works better.

How Can Regular Maintenance And Balancing Of Milling Cutters Contribute To Improved Safety And Reduced Downtime In A Manufacturing Environment?Regular maintenance of milling cutters means we check and fix them before they break. This keeps machines running safely. If the cutters are balanced, they won’t shake or cause accidents. When everything works well, we waste less time fixing things, so we can make more products. This makes the factory safer and more efficient.