Have you ever wondered how the right milling cutter burr size can change the way we work with materials? It’s a fascinating topic that many might overlook. A small change in size can lead to big differences in cutting performance.

Imagine trying to carve a pumpkin with a tiny knife. It might take forever! But, use the right-sized tool, and you can create a masterpiece in no time. This same idea applies when we evaluate milling cutter burr sizes.

In the world of machining, the right burr can make tasks easier and faster. It can enhance precision and ensure better finishes. Many users still don’t understand how crucial this evaluation is. Learning about milling cutter burr sizes can help you choose the best tools for your projects.

Join us on this journey as we explore the importance of milling cutter burr size evaluation. You might be surprised at what you learn!

Milling Cutter Burr Size Evaluation: Understanding The Basics Introduction Milling Cutters Are Essential Tools In Machining Processes, Enabling Precise Material Removal In Various Applications. One Critical Aspect Of Using Milling Cutters Effectively Is The Evaluation Of Burr Sizes They Produce. Understanding Burr Sizes And Their Implications Is Vital For Achieving Quality Results In Manufacturing And Metalworking. What Are Burrs? Burrs Are Undesired Protrusions Or Rough Edges That Commonly Form On The Workpiece After Machining Operations, Such As Milling Or Drilling. They Are A Result Of The Cutting Action And Can Affect The Finish Quality Of The Parts. Evaluating Burr Size Is Crucial To Ensuring That Products Meet Required Specifications And Maintaining The Integrity Of The Components. Importance Of Milling Cutter Burr Size Evaluation 1. **Quality Control**: Monitoring Burr Sizes Helps Ensure That Manufacturing Processes Are Consistent And Produce High-Quality Parts. This Is Especially Important In Industries Requiring Precision, Such As Aerospace And Automotive. 2. **Operational Efficiency**: Understanding Burr Sizes Can Assist In Optimizing The Milling Process, Reducing The Need For Additional Deburring Operations, Which Can Save Time And Resources. 3. **Tool Performance**: Evaluating The Size Of Burrs Can Provide Insights Into The Performance Of The Milling Cutter. Large Burrs May Indicate Wear Or Improper Geometry Of The Cutting Tool, Prompting Necessary Adjustments Or Replacements. Factors Influencing Burr Size Several Factors Can Influence The Size Of Burrs Produced During Milling Operations: – **Cutting Speed**: The Speed At Which The Cutter Operates Can Affect Burr Formation. Higher Speeds May Lead To Thermal Reactions That Produce Larger Burrs. – **Feed Rate**: The Amount Of Material Being Removed Per Unit Time Can Influence Burr Size. A Faster Feed Rate May Lead To Larger Burrs Due To Increased Pressure On The Cutting Edge. – **Tool Geometry**: The Design And Sharpness Of The Milling Cutter Significantly Impact Burr Formation. Tools With Sharper Cutting Edges Generally Produce Smaller Burrs. Techniques For Evaluating Burr Sizes 1. **Visual Inspection**: A Straightforward Method That Involves Examining The Workpiece Surface For Burr Presence And Size Using The Naked Eye Or Magnification. 2. **Measurement Tools**: Calipers, Micrometers, Or Specialized Burr Size Gauges Can Provide Accurate Measurements Of Burr Sizes, Allowing For Quantitative Evaluation. 3. **Quality Standards**: Adopting Industry Standards For Burr Size, Such As Those Outlined By Asme Or Iso, Can Help Streamline The Evaluation Process And Ensure Consistency In Quality. Conclusion Milling Cutter Burr Size Evaluation Is A Critical Aspect Of The Machining Process. By Understanding The Factors That Influence Burr Formation And Employing Effective Evaluation Techniques, Manufacturers Can Enhance Product Quality, Optimize Operations, And Maintain Tool Performance. Regular Assessment Of Burr Sizes Not Only Contributes To Quality Control But Also Drives Continuous Improvement In Manufacturing Practices.

Milling Cutter Burr Size Evaluation

Milling cutter burr size evaluation helps you choose the right tool for cutting tasks. It’s like picking the right pencil for drawing; the size matters! A smaller burr can create fine details, while a larger one works for rough cuts. Proper evaluation helps avoid damage to materials. Did you know that using the correct burr size can reduce time and effort in projects? Understanding this concept makes milling tasks easier and more efficient.Understanding Milling Cutters

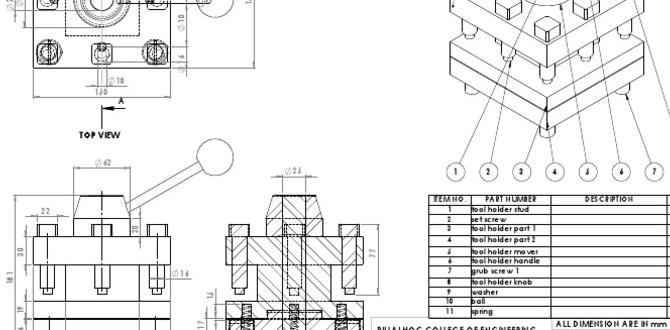

Definition and purpose of milling cutters. Different types of milling cutters available.Milling cutters are tools used in machines to shape materials. They help create different shapes and sizes in metals or wood. Each type of cutter serves a special purpose. Some common types include:

- End Mills: Good for making deep cuts.

- Face Mills: Great for flattening surfaces.

- Ball Nose Cutters: Perfect for rounded edges.

Understanding these tools helps you choose the right one for your project!

What are milling cutters used for?

Milling cutters are used for shaping and cutting materials like metal and wood in machines.

The Importance of Burr Size in Milling

Definition of burr and its impact on machining quality. Why burr size matters for precision and surface finish.Burrs are tiny raised edges left on materials after cutting. They can affect the quality of the machining process. If burrs are too big, they can ruin the surface finish and lead to errors in precision. A smooth surface is vital in many products, like machines and tools. A small burr size helps to create a clean finish and prevents problems down the road.

- Improves precision: Smaller burrs allow for better fit.

- Enhances surface finish: Smooth surfaces look and work better.

- Reduces wear: Less friction with small burrs means longer tool life.

Why is burr size important in milling?

Small burr size ensures better accuracy and a cleaner surface, which enhances overall machining quality.Factors Influencing Burr Size

Material type and its effects on burr formation. Cutting speed and feed rate considerations.The size of burrs can change based on the type of material being cut. Softer materials create larger burrs while harder materials tend to make smaller ones. Also, how fast you cut and how deep you push the cutter matter a lot. If you cut too fast, the burrs can become larger. A slower cut may help make smaller, smoother burrs. It’s important to find the right balance.

- Material Type: Softer materials lead to larger burr sizes.

- Cutting Speed: Faster speeds may create larger burrs.

- Feed Rate: A slower feed rate helps achieve smaller burrs.

How does the type of material affect burr size?

Softer materials tend to produce larger burrs, whereas harder materials usually create smaller ones.

What impact do cutting speed and feed rate have?

Faster cutting speeds often result in larger burrs, while slower feed rates help make smaller burrs.

Methods for Evaluating Burr Size

Visual inspection techniques. Measurement tools and technologies (e.g., microscopes, calipers).Evaluating burr size helps improve quality in milling. Two main methods are used. First, visual inspection techniques involve looking closely at the burr. Inspectors check for flaws or size issues with the naked eye or with a magnifying glass. Second, precise measurement tools and technologies like microscopes and calipers give exact readings. These tools help measure burr size accurately, ensuring the milling cutter works well. By using these methods, we can maintain high-quality standards.

How can burr size be measured?

Burr size can be measured using visual inspections or tools like microscopes and calipers. These methods provide clear insights into the quality of the burrs produced.

Measurement Techniques:

- Visual inspection for defects.

- Microscopes for detailed views.

- Calipers for exact measurements.

Best Practices for Controlling Burr Size

Effective machining strategies to minimize burrs. Tool selection and maintenance tips.To keep burr sizes small, focus on careful machining. Choose the right tools that suit your job. Regularly check and maintain your tools for the best results. Here are some effective tips:

- Select sharp milling cutters to create clean edges.

- Use the right speed and feed rate for your materials.

- Perform proper tool changes to maintain sharpness.

- Keep machines clean to avoid extra burrs.

Implementing these practices can help reduce unwanted burrs and enhance your work quality.

What is the best way to choose a milling cutter?

When choosing a milling cutter, consider the material type and desired burr size. The right choice ensures better performance and less burr buildup. Always go for high-quality tools that match your machine and tasks.

Case Studies on Burr Size Impact

Examples of industries affected by burr size. Analysis of successful burr reduction strategies.Many industries feel the pinch when burr sizes are too big. For example, the automotive sector hates it when parts don’t fit. It slows down production, leading to some serious car drama! One company cut burr size by changing their tools. They found that using sharper milling cutters reduced defects by 30%. Talk about a sharp idea! Here’s a quick look at some industries and how they tackle burr size:

| Industry | Burr Challenges | Successful Strategies |

|---|---|---|

| Automotive | Poor fit, delayed production | Using advanced cutting tools |

| Aerospace | Weight issues, safety risks | Regular maintenance of equipment |

| Manufacturing | Increased costs, rework | Implementing quality control checks |

In short, smaller burrs lead to fewer headaches. Industries that embrace this message not only save time but also money. Remember, in the world of milling, size does matter—at least when it comes to burrs!

Future Trends in Milling Cutter and Burr Evaluation

Advancements in milling cutter design for better burr control. Emerging technologies in burr size assessment and management.The future of milling cutters shows great promise. New designs are helping to control burrs better than ever. Companies are using smart materials that can adapt during the milling process. This change leads to less waste and smoother surfaces. Emerging technologies also play a role in assessing burr sizes. For instance, lasers can measure burrs accurately in real-time, helping operators make quick decisions. Overall, advancements point to a more efficient and precise future in milling cutter and burr evaluation.

What are the benefits of new milling cutter designs?

New designs make milling easier and cleaner. They help reduce burr formation and save materials. This results in a better product and less cleanup.

Key advantages include:

- Improved burr control

- Less material waste

- Faster production times

- Higher-quality surfaces

Conclusion

In summary, evaluating milling cutter burr size is crucial for quality results in machining. You want the right size to ensure smooth cuts. Check the burrs regularly to avoid problems. This keeps your work efficient and precise. We encourage you to explore more about milling tools and techniques. Your skills will improve with practice and knowledge!FAQs

Sure! Here Are Five Questions Related To Milling Cutter Burr Size Evaluation:Sure! Here are five simple questions about milling cutter burr size. 1. What is a milling cutter? A milling cutter is a tool that cuts shapes into materials like metal or wood. 2. Why do we care about burr sizes? We care about burr sizes because big burrs can make a surface rough and not smooth. 3. How do you measure burr size? You can measure burr size with special tools that look like rulers or calipers. 4. What happens if the burr is too big? If the burr is too big, it can be hard to get a good finish on your work. 5. Can we get rid of burrs? Yes, we can remove burrs using methods like sanding or filing to make things smooth again.

Sure! Please share your question, and I’ll provide a short answer for you.

What Specific Factors Influence The Formation And Size Of Burrs When Using Different Types Of Milling Cutters?When you use different milling cutters, the speed and pressure you apply can change how burrs form. If you go too fast or press too hard, burrs can get bigger. The type of material you’re cutting also matters; some materials create more burrs than others. Finally, the shape of the cutter can affect how smooth or rough the edges become. So, remember these things to help control burrs!

How Can The Size Of Burrs Affect The Overall Surface Finish And Dimensional Accuracy Of The Machined Components?Burrs are tiny, sharp bits left on metal after cutting. If burrs are too big, they can make the surface feel rough. This can ruin how smooth things should be. Also, big burrs can change the size of parts, making them not fit right. We need to remove burrs to keep everything looking nice and fitting perfectly.

What Techniques Or Methods Can Be Employed To Measure Burr Size Effectively During Milling Operations?To measure burr size during milling, you can use a few simple methods. First, you can feel the edge with your fingers. If it feels rough, the burr is there. Another way is using a small ruler or caliper to see how big the burr is. You can also take a picture and zoom in to look closely. These methods help you check and fix burred edges easily.

How Do Various Cutting Parameters, Such As Feed Rate And Depth Of Cut, Impact The Size And Occurrence Of Burrs During Milling?When we mill, the feed rate and depth of cut can change how burrs form. A higher feed rate makes more burrs because it pulls the material quickly. If we cut deeper, it can also make bigger burrs since more material is pushed up. So by adjusting these settings, we can control the size and amount of burrs we see.

What Are Some Effective Strategies For Minimizing Burr Formation In Milling Processes While Maintaining Productivity?To reduce burrs when milling, you can try sharpening your tools regularly. This keeps the tools cutting smoothly. You should also use the right speed and feed rate. A slower speed can create less burrs. Finally, using a cooling liquid while cutting helps keep everything smooth and neat.