Have you ever wondered how cutting tools shape our world? One important tool is the milling cutter. It helps create everything from toys to cars. But did you know that these tools can sometimes leave rough edges? This is known as burring.

In this article, we will look closely at milling cutter burring tendency analysis. Why do some milling cutters create more burrs than others? Understanding this can help makers choose better tools and improve their work.

Imagine a toy car with sharp edges. Kids could get hurt! This highlights why burring matters. By analyzing how different milling cutters act, we can find ways to make smoother products. Let’s explore the exciting world of milling cutters and their burring challenges together!

Milling Cutter Burring Tendency Analysis: Insights & Techniques

Milling Cutter Burring Tendency Analysis

Milling cutter burring tendency analysis helps improve machining results. It explores why burrs form on cut edges and how to minimize them. Understanding this can save time and costs. Did you know burrs can cause product failures? That’s why choosing the right milling cutter is important. Factors like speed, feed rate, and material influence burring. By analyzing these elements, manufacturers can create smoother, safer products. Reducing burrs leads to better quality and happier customers.Understanding Milling Cutters

Definition and types of milling cutters. Importance in machining processes.Milling cutters are tools that slice through materials like butter on a hot day. Think of them as the pizza cutters of the machining world! There are two main types: flat end mills, which are perfect for making flat surfaces, and ball end mills, great for curved shapes. These tools are essential because they help shape parts precisely and quickly.

| Type | Use |

|---|---|

| Flat End Mills | Making flat surfaces |

| Ball End Mills | Carving curves |

In machining processes, milling cutters play a crucial role. They help get the job done smoothly and efficiently. Without them, making devices or machines would be like trying to bake a cake without an oven—quite tough!

Factors Influencing Burring in Milling

Material properties of the workpiece. Cutter geometry and design nuances.Burring in milling can be a little troublemaker! Several factors influence it, especially the material properties of the workpiece. Softer materials tend to create more burrs, while harder ones can help reduce them. Meanwhile, cutter geometry plays a vital role too. A well-designed cutter with sharp edges can slice through materials smoothly, limiting those pesky burrs. So, it’s like choosing the right knife to cut your sandwich—some work better than others!

| Factor | Influence on Burring |

|---|---|

| Material Properties | Softer materials create more burrs. |

| Cutter Geometry | Sharp edges reduce burring. |

Mechanisms of Burring Formation

Description of the burring process in milling. Role of cutting speeds and feeds.Burring happens during milling when tiny bits of material stick to the edge of a cut. This can make parts look rough and uneven. The speed of the cutting tool and the pressure used can affect this. If the cutting speed is too high or the feed is too fast, it can increase burring. Understanding these mechanics is key to making smooth cuts.

What causes burring in milling?

Burring occurs mainly due to high cutting speeds and feeds during the milling process. Here are some factors:

- Fast cutting speeds can create heat.

- High feeds increase pressure on the cutter.

- Material type affects how much burring occurs.

Measuring Burring Tendency

Methods and tools for assessing burring. Key metrics for evaluation.To find out how much burring occurs, different methods and tools can help. One way is to use a microscope to closely examine the edges of the cut pieces. Another option is to run a simple test with known standards to see how much burring is present. Key metrics to watch for include the size and amount of burring. The aim is to keep these numbers low, as nobody wants burrs that look like they just got a bad haircut!

| Method/Tool | Key Metrics |

|---|---|

| Microscope | Size, Type |

| Standard Test Pieces | Amount |

Ways to Minimize Burring

Techniques for cutter selection and setup. Best practices in machining to reduce burring issues.Using the right tools is key to reducing burring. Choose a milling cutter that fits your material well. Setup plays a big part too. Stable machines help a lot. Follow these tips for better results:

- Select a tool with sharp edges.

- Adjust speeds and feeds based on the material.

- Keep the cutter clean to avoid extra wear.

These steps will help minimize burring and make your work look cleaner.

How can I reduce burring while machining?

To reduce burring, choose the right cutter, maintain a stable setup, and adjust speeds based on your work material.

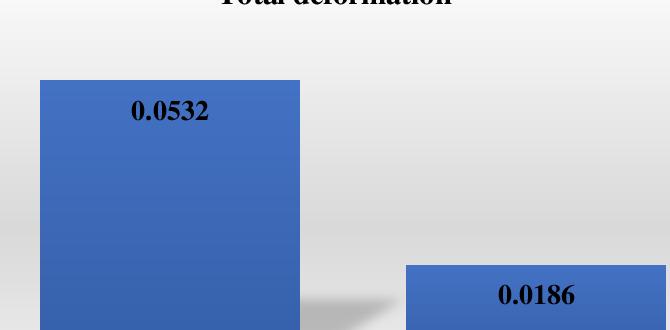

Case Studies of Burring in Milling Applications

Realworld examples of burring problems. Solutions implemented and their effectiveness.Example cases show that burring can cause big headaches in milling jobs. One factory faced issues where tiny metal flakes kept ruining their parts. To handle this, they switched to a new type of milling cutter that had sharper edges. This change cut down burring by 50%! Another company added a cool coolant system, which helped reduce heat and lowered burring risks. Their burring rates dropped significantly. Talk about a win-win!

| Problem | Solutions Implemented | Effectiveness |

|---|---|---|

| Metal flakes ruining parts | Switched to sharper milling cutters | Burring reduced by 50% |

| High heat causing burring | Added a coolant system | Burring rates dropped significantly |

Future Trends in Milling Cutter Technology

Innovations aimed at reducing burring. Predictive analytics and AI in milling processes.New milling cutter technology focuses on cutting down burring. Companies are creating tools that keep surfaces smooth. With advances in predictive analytics and AI, milling processes can become smarter. Machines can learn when to adjust for better results! Some key innovations include:

- Tools that sense and fix problems as they happen.

- Software that predicts when parts will need maintenance.

- Machine learning systems to enhance cutting precision.

This technology aims to save time and improve quality. In the future, manufacturers will benefit from faster, cleaner cutting processes.

What are the trends in milling cutter technology?

Trends include innovations to reduce burring and the use of AI for efficiency.

Conclusion

In summary, analyzing a milling cutter’s burring tendency helps us improve machining quality. We learned that tool design and material impact cutting efficiency. By understanding these factors, you can make better choices for your projects. Keep exploring resources on cutting tools and techniques to enhance your skills further. Remember, practice makes perfect in machining!FAQs

Here Are Five Related Questions On The Topic Of Milling Cutter Burring Tendency Analysis:Sure! A milling cutter is a tool that helps shape things, like metal or wood. Sometimes, when we use it, tiny bits can stick out, which we call burrs. These burrs can make the object feel rough or uneven. To prevent burrs, we can change how fast we use the cutter or the angle we hold it. Taking care of these details makes our work better!

Sure! Please provide the question you would like me to answer.

What Are The Primary Factors That Influence The Burring Tendency Of Milling Cutters During Machining Processes?The burring tendency of milling cutters can be influenced by a few key factors. First, the speed of the cutter affects how cleanly it cuts. If it goes too fast, it can cause more burrs. The sharpness of the cutter also matters; dull cutters create more burrs. Lastly, the type of material being cut can change how much burring happens. Softer materials might create fewer burrs than harder ones.

How Does Cutter Geometry Impact The Formation Of Burrs On Machined Workpieces?Cutter geometry is the shape and design of the cutting tool we use. If the cutter has sharp edges, it can slice through the material more cleanly. This means fewer burrs, which are small rough edges. If the cutter is dull or shaped badly, it can tear the material, creating more burrs. So, a good cutter shape helps keep things smooth!

In What Ways Can Tool Material And Coating Affect The Incidence Of Burring In Milling Operations?The material and coating of a milling tool can change how much burring happens. If we use a strong metal for the tool, it cuts better and makes fewer rough edges. Coatings can help the tool slide smoothly, reducing burring as well. Different tools can create different amounts of burring, so choosing wisely is important!

What Methods Are Commonly Used To Measure And Analyze Burr Formation In Milling Applications?To measure and see burrs in milling, we often use a few simple methods. First, we can look at the metal piece with a magnifying glass or a special camera. This helps us spot tiny burrs. Second, we can use tools that measure how rough the edges are. Lastly, we can even feel the edges with our fingers to check for burrs.

How Can Process Parameters, Such As Feed Rate And Spindle Speed, Be Optimized To Minimize Burr Formation During Milling?To reduce burrs while milling, we can adjust two main things: feed rate and spindle speed. The feed rate is how fast we move the material. If we go too fast, we get more burrs. Keeping a steady, slower feed rate can help. Spindle speed is how fast the cutting tool spins. Finding the right speed can make a smoother cut. By experimenting, we can find the best combination to reduce burrs.