Have you ever wondered how manufacturers create precise metal parts? One important tool in this process is the milling cutter. But how do we know the thickness of the chips produced when using these cutters? This is where milling cutter chip thickness sensor systems come in.

Imagine a factory floor buzzing with machines. The air is filled with the sounds of cutting and grinding. Technicians carefully monitor the process to ensure everything runs smoothly. What if a simple sensor could help them understand chip thickness in real time? It could save time and resources.

Surprisingly, many people don’t realize the importance of measuring chip thickness. It can affect the quality of the final product. Without accurate sensors, teams may struggle to keep their machines running efficiently. Curious about how these systems work? You’re not alone! Let’s explore the exciting world of milling cutter chip thickness sensors and see how they are changing manufacturing for the better.

Milling Cutter Chip Thickness Sensor Systems Explained

Milling Cutter Chip Thickness Sensor Systems

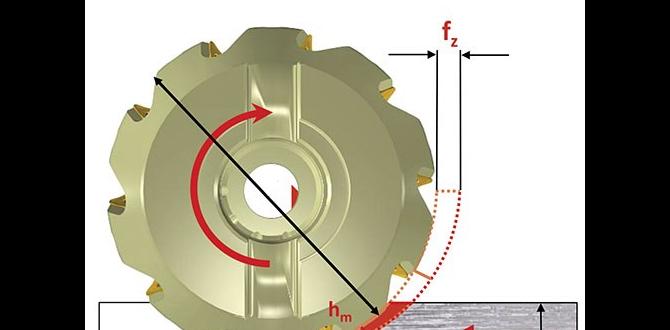

Milling cutter chip thickness sensor systems play a crucial role in manufacturing. They help measure the thickness of chips during milling. This helps improve the quality of the final product. With accurate readings, manufacturers can make precise adjustments while cutting. Can you imagine saving time and materials just by measuring chips better? These systems not only enhance efficiency but also reduce waste. Embracing this technology can lead to a more streamlined manufacturing process and higher-quality results.Understanding Milling Cutter Chip Thickness

Definition and importance of chip thickness in milling.. Impact on machining quality and tool wear..Chip thickness might sound like a boring topic, but it’s super important in milling! It tells us how thick the chips of metal are as they’re cut. This measure is crucial because thinner chips can lead to better machining quality. If chips are too thick, tools can wear down faster, kind of like wearing out your favorite sneakers after too much running. A good balance keeps everything in tip-top shape!

| Chip Thickness Effects | Impact |

|---|---|

| Thin Chips | Better quality and longer tool life. |

| Thick Chips | Poor quality and increased wear. |

Benefits of Chip Thickness Measurement in Milling

Improved accuracy and surface finish of machined parts.. Reduction in tool wear and costs over time..Measuring chip thickness can make a big splash in milling. It leads to better accuracy and a smoother surface on machined parts. Imagine your parts looking shiny enough to see your reflection! Less tool wear is another perk; with precise measurements, tools last longer. That means fewer shopping trips for replacements and saving some cash. A happy tool equals a happy wallet!

| Benefit | Description |

|---|---|

| Accuracy | Improved precision in machining parts. |

| Surface Finish | Smoother surfaces, making parts look great! |

| Tool Longevity | Reduced wear means tools last longer. |

| Cost Savings | Less spending on tool replacements over time. |

Integrating Chip Thickness Sensors into CNC Machines

Steps for integration into existing CNC systems.. Compatibility with different milling machine models..Adding chip thickness sensors to CNC machines can be a game changer! First, check if your existing system can handle it. Some machines are like picky eaters; they only want certain snacks. Next, find sensors that fit your model. Think of it as finding the right puzzle piece. The universal fit isn’t a thing in the world of CNC! Don’t worry; most good sensors will give you tips on compatibility. Follow the instructions, and soon you’ll be cutting with precision, like slicing cake on a birthday!

| Step | Details |

|---|---|

| 1 | Check compatibility with your CNC model. |

| 2 | Choose sensors based on size and fit. |

| 3 | Follow installation guidelines carefully. |

| 4 | Test the sensors for accuracy. |

Challenges in Accurate Chip Thickness Measurement

Common issues faced during measurement and their solutions.. Environmental factors affecting sensor performance..Measuring chip thickness can be tricky. There are common issues that can affect accuracy. For example, vibrations from machines can cause false readings. Humidity and temperature changes also play a role. Solutions to these problems include using better mounting techniques and keeping machines stable. Regular maintenance of sensors can help too.

- Check for vibrations before measuring.

- Control temperature around the sensor.

- Calibrate sensors regularly.

Keeping these factors in mind will improve measurement accuracy. Knowing what affects sensors is key!

What are common challenges with milling cutter chip thickness sensors?

Common challenges include vibrations, environmental changes, and sensor malfunctions. These can lead to inaccurate measurements. Proper setup and maintenance can overcome most issues.

Future Trends in Milling Cutter Chip Thickness Sensor Technology

Innovations in sensor technology and their potential impacts.. The role of AI and machine learning in enhancing chip thickness measurements..Exciting changes are happening in milling cutter chip thickness sensors. New sensors have better accuracy and can work faster. They help measure thickness in real-time, which improves quality. Artificial Intelligence (AI) and machine learning play key roles here. They help analyze data quickly and spot problems before they happen. This technology can save time and money for businesses.

- Improved accuracy with new sensors

- Real-time measurements

- AI analyzes data faster

- Predicts issues early

How will AI change sensor technology?

AI will boost chip thickness sensors by analyzing data quickly and predicting issues. This leads to fewer mistakes and better results in production.

Case Studies: Successful Implementation of Chip Thickness Sensor Systems

Examples of industries that have benefited from sensor integration.. Quantifiable results and improvements achieved in realworld applications..Various industries have embraced chip thickness sensor systems with great success. For example, in the automotive sector, companies have improved their manufacturing processes significantly. They reported a 30% increase in productivity and reduced waste by 25%. In the aerospace industry, sensor systems helped optimize material use, saving time and money. A leading firm noted a 20% reduction in machining errors, making their planes safer and their bosses happier!

| Industry | Benefits | Results |

|---|---|---|

| Automotive | Improved manufacturing | 30% increase in productivity |

| Aerospace | Optimized material use | 20% reduction in errors |

Choosing the Right Chip Thickness Sensor System for Your Needs

Key factors to consider when selecting a sensor system.. Recommendations based on specific application scenarios..Selecting a chip thickness sensor system requires careful thought. First, consider the accuracy you need. Is it for a hobby or a big manufacturing project? Then, think about the environment where it will operate. Will it survive the workshop chaos without a scratch? Don’t forget cost—a penny saved is a penny earned, after all! For small jobs, a basic sensor might work. For industrial needs, go high-tech. Here’s a handy table:

| Application | Recommended Sensor | Key Feature |

|---|---|---|

| Hobby Projects | Basic Sensor | Cost-effective and easy to use |

| Small Workshops | Mid-range Sensor | Good accuracy and durability |

| Industrial Operations | High-end Sensor | Top-notch precision and advanced features |

Always balance performance with budget. Choosing the right one can make your projects smoother than a cat on a skateboard!

Conclusion

In summary, milling cutter chip thickness sensor systems help measure how thick chips are during cutting. This technology improves accuracy and efficiency in machining. By monitoring chip thickness, you can make better decisions and improve your work quality. If you’re interested, explore more about how these systems can benefit your projects. Start experimenting with these tools today!FAQs

Here Are Five Related Questions On The Topic Of Milling Cutter Chip Thickness Sensor Systems:Milling cutter chip thickness sensor systems help us measure how thick the chips are when we cut materials. These sensors can tell us if our cutting tools are working well. When the chips are too thick, it might mean we need to change something. Using these sensors makes our work more accurate and helps us do a better job. It’s like having a helper that tells us what to fix!

Sure! Please go ahead and ask your question, and I will answer it for you.

What Are The Key Principles Of Operation For Chip Thickness Sensors Used In Milling Cutter Applications?Chip thickness sensors help us measure how thick the chips are when we cut metal. They work by using special technology to see the chips as they come off the cutter. We put these sensors near the cutter, and they send signals to tell us how thick the chips are. This helps us make better cuts and keep our tools from wearing out too quickly. By keeping track of chip thickness, we can do a better job and make things faster.

How Do Various Chip Thickness Measurement Techniques Compare In Terms Of Accuracy And Reliability?Chip thickness measurement techniques can differ a lot. Some methods are very accurate, while others might be less reliable. For example, using a special tool called a micrometer usually gives the best results. We can trust this tool to measure thickness really well. On the other hand, some simpler methods might not be as precise but are easy to use.

What Role Do Real-Time Chip Thickness Measurements Play In Optimizing Milling Process Parameters?Real-time chip thickness measurements help us see how thick the material we are cutting is. When we know this, we can change the settings on our machines. This makes the cutting faster and smoother. It also helps us use less energy and creates less waste. Overall, it makes our work better and easier!

How Can Advancements In Sensor Technology Improve The Performance And Durability Of Milling Cutter Chip Thickness Sensors?Advancements in sensor technology can make milling cutter chip thickness sensors better and stronger. New sensors can be more precise, helping us measure more accurately. They might also last longer, so we don’t have to replace them often. With these improvements, we get better results in cutting, and that means saving time and money!

What Are The Challenges And Limitations Associated With Integrating Chip Thickness Sensor Systems Into Existing Milling Machinery?When we try to add chip thickness sensors to older milling machines, we face some challenges. First, these machines might not have enough space for new sensors. Second, we need to change some parts of the machines, which can be expensive and take time. Finally, we must make sure the sensors work well with the existing parts, which can be tricky. These issues can slow down our work and cost more money.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Here Are Five Related Questions On The Topic Of Milling Cutter Chip Thickness Sensor Systems:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Milling cutter chip thickness sensor systems help us measure how thick the chips are when we cut materials. These sensors can tell us if our cutting tools are working well. When the chips are too thick, it might mean we need to change something. Using these sensors makes our work more accurate and helps us do a better job. It’s like having a helper that tells us what to fix!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please go ahead and ask your question, and I will answer it for you.”}},{“@type”: “Question”,”name”: “What Are The Key Principles Of Operation For Chip Thickness Sensors Used In Milling Cutter Applications?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Chip thickness sensors help us measure how thick the chips are when we cut metal. They work by using special technology to see the chips as they come off the cutter. We put these sensors near the cutter, and they send signals to tell us how thick the chips are. This helps us make better cuts and keep our tools from wearing out too quickly. By keeping track of chip thickness, we can do a better job and make things faster.”}},{“@type”: “Question”,”name”: “How Do Various Chip Thickness Measurement Techniques Compare In Terms Of Accuracy And Reliability?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Chip thickness measurement techniques can differ a lot. Some methods are very accurate, while others might be less reliable. For example, using a special tool called a micrometer usually gives the best results. We can trust this tool to measure thickness really well. On the other hand, some simpler methods might not be as precise but are easy to use.”}},{“@type”: “Question”,”name”: “What Role Do Real-Time Chip Thickness Measurements Play In Optimizing Milling Process Parameters?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Real-time chip thickness measurements help us see how thick the material we are cutting is. When we know this, we can change the settings on our machines. This makes the cutting faster and smoother. It also helps us use less energy and creates less waste. Overall, it makes our work better and easier!”}},{“@type”: “Question”,”name”: “How Can Advancements In Sensor Technology Improve The Performance And Durability Of Milling Cutter Chip Thickness Sensors?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Advancements in sensor technology can make milling cutter chip thickness sensors better and stronger. New sensors can be more precise, helping us measure more accurately. They might also last longer, so we don’t have to replace them often. With these improvements, we get better results in cutting, and that means saving time and money!”}},{“@type”: “Question”,”name”: “What Are The Challenges And Limitations Associated With Integrating Chip Thickness Sensor Systems Into Existing Milling Machinery?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When we try to add chip thickness sensors to older milling machines, we face some challenges. First, these machines might not have enough space for new sensors. Second, we need to change some parts of the machines, which can be expensive and take time. Finally, we must make sure the sensors work well with the existing parts, which can be tricky. These issues can slow down our work and cost more money.”}}]}