Have you ever wondered how machines cut materials so precisely? One important tool in this process is the milling cutter. But what keeps these cutters firmly in place while they work? It’s all about clamping force.

When a milling cutter spins, it needs a strong grip. If it’s too loose, the cutter can slip or break. That’s why verifying the clamping force is crucial. Without it, you might face unexpected problems. And nobody likes surprises in the workshop, right?

Did you know that proper clamping can improve the quality of your cuts? It can also make your machine last longer. That’s a win-win for any builder or hobbyist!

In this article, we’ll dive deep into milling cutter clamping force verification. We’ll explore why it matters and how to do it correctly. Join us as we uncover the secrets to perfect cuts and stronger tools!

Milling Cutter Clamping Force Verification: Importance And Methods

Milling Cutter Clamping Force Verification

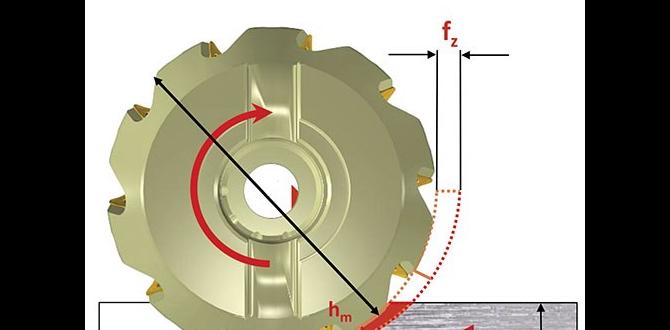

Milling cutter clamping force verification checks how well a cutter stays in place while working. It’s crucial for safe and accurate machining. If a cutter is loose, it can wobble and cause damage. Imagine a tightrope walker. If they lose balance, they may fall. Similarly, a milling cutter needs the right force to stay put. Regular checks help ensure efficiency and a smooth process in manufacturing. Knowing how to verify this can save time and money!Understanding Clamping Force in Milling

Definition of clamping force and its importance in milling operations.. Factors influencing clamping force during machining processes..Clamping force is like a strong hug for your workpiece during milling. It holds everything tightly in place, which is very important. If the force is too weak, your workpiece might dance around—and nobody wants that! Factors like the type of material, machine settings, and tool shape can affect this force. Think of it as balancing on a seesaw; too much weight on one side makes it flip!

| Factors | Description |

|---|---|

| Material Type | Harder materials usually require higher clamping force. |

| Machine Settings | Speed and feed rates impact how well the clamping works. |

| Tool Shape | Different shapes grip differently, like hands holding a ball. |

Methods for Measuring Clamping Force

Description of various measurement techniques (force sensors, strain gauges, etc.). Pros and cons of each method in terms of accuracy and practicality..There are several fun ways to measure clamping force. One method uses force sensors that give a precise reading. They’re great but can be a bit pricey. Another option is strain gauges, which are like tiny weights that bend when you apply force. They are cheaper, but you might need some extra math skills to understand the readings. Each technique has its quirks; one is fancy, while the other might make you feel like a science genius!

| Method | Pros | Cons |

|---|---|---|

| Force Sensors | Precise readings | Higher costs |

| Strain Gauges | Cost-effective | More calculations needed |

Importance of Clamping Force Verification

How accurate clamping force impacts machining quality and tool life.. Case studies highlighting failures due to improper clamping forces..Clamping force is like a tight hug for your tools. If it’s too loose, things go haywire! Accurate clamping keeps the milling cutter steady, improving machining quality and tool life. When the force isn’t right, tools wear faster, leading to costly mistakes. A case study showed that a simple mistake in clamping led to a broken tool, costing the company $10,000. That’s enough money to buy a robot! So, pay attention to your clamping force!

| Error Type | Cost Impact |

|---|---|

| Improper Clamping | $10,000 |

| Tool Wear | $5,000 |

Steps for Conducting Clamping Force Verification

Detailed procedural steps for verifying clamping force in the workshop.. Tools and equipment required for effective verification..To check the clamping force in the workshop, follow these easy steps. First, gather your tools. You’ll need a torque wrench and a force gauge. Next, securely place the milling cutter on the machine. Tighten it gently, then use the torque wrench to measure the force needed to hold it steady. Record the readings; this data is golden! Finally, compare your results against the manufacturer’s guidelines. If it’s off, you may need to adjust your clamping setup.

| Tools Needed | Purpose |

|---|---|

| Torque Wrench | Measures tightening force |

| Force Gauge | Checks holding strength |

Common Challenges and Solutions in Clamping Force Verification

Typical issues encountered during verification and their causes.. Potential solutions to enhance the accuracy of clamping force measurements..Clamping force verification can come with some tricky problems. Here are a few you might see:

- Wrong measurements due to worn tools.

- Inconsistent readings from the measuring device.

- Improper setup or alignment of the milling cutter.

To fix these issues, consider these tips:

- Regularly check tools for wear.

- Calibrate measuring devices often.

- Ensure correct setup each time.

Being careful can lead to better and more accurate measurements!

What are the common issues in clamping force verification?

Typical problems include worn tools, inconsistent readings, and improper setup. These can lead to incorrect measurements.

What solutions improve clamping force measurements?

Regular tool checks, device calibration, and proper setup enhance accuracy. Following these tips can help prevent problems.

Best Practices for Maintaining Clamping Force

Recommendations for setting optimal clamping force based on cutter type and material.. Maintenance protocols to ensure consistent clamping force over time..To keep your clamping force working well, use the right settings based on your cutter type and material. Different cutters need different force levels. For example, a harder material like steel needs a stronger grip. Always check your equipment and make sure everything is clean. Dust and grime can cause problems, like a sneeze in a quiet room! Follow these maintenance protocols to keep the force steady over time:

| Cutter Type | Recommended Force |

|---|---|

| HSS Cutter | Medium |

| Carbide Cutter | High |

With a little care, your clamping force can keep working like a champ. And remember, a firm grip is just as important in machining as it is in a good handshake!

Future Trends in Clamping Force Measurement Technology

Emerging technologies and innovations in clamping force verification.. The role of automation and smart sensors in improving machining practices..New tools are coming for checking clamping force. These tools include better sensors and smart devices. They help machines work faster and more accurately. Automation is changing the game. Machines can now measure their own clamping force. This makes work smoother. With smart sensors, we get real-time data. It’s easier to avoid mistakes. Innovation in this area leads to higher productivity and less waste. The future looks bright for machining!

What are emerging technologies in clamping force verification?

Emerging technologies include smart sensors and advanced automation systems. These innovations help machines check clamping force accurately.

Key Innovations:

- Smart sensors for real-time data.

- Automation systems that minimize human error.

- Machine learning for continuous improvement.

Conclusion

In conclusion, verifying milling cutter clamping force is crucial for precision and safety. Accurate clamping prevents cutting errors and tool damage. You can improve your work by regularly checking this force. This simple step can boost your projects’ quality. For more tips and techniques, consider exploring additional resources on milling and clamping force verification. Happy milling!FAQs

Certainly! Here Are Five Questions Related To Milling Cutter Clamping Force Verification:Sure! Here are five questions we can ask about checking how tightly a milling cutter is held: 1. Why do we need to check the clamping force? 2. How can we tell if the clamping force is too weak? 3. What tools can we use to measure the clamping force? 4. How often should we check the clamping force? 5. What happens if the clamping force is not enough? These simple questions help us understand how to keep our tools safe and working well.

Sure! Please let me know the question you want me to answer.

What Methods Are Commonly Used To Measure The Clamping Force Of A Milling Cutter During Operation?To measure how tightly a milling cutter is held, we can use a few methods. One way is to use special tools called load cells. These tools measure how much force is pressing down. We can also use a dial gauge to check if the cutter moves too much. Both methods help us make sure everything is safe while we work.

How Does Inadequate Clamping Force Affect Machining Precision And Tool Life In Milling Operations?If the clamping force is too weak, the part we are working on can move around during milling. This movement makes it hard to cut everything evenly, which means we get less precise shapes. Also, moving parts can wear out the tools faster. This means we have to replace tools more often, which can take time and cost money. So, strong clamping helps keep our work and tools in good shape.

What Are The Recommended Torque Values For Different Types Of Milling Cutter Holders To Ensure Optimal Clamping Force?For milling cutter holders, the recommended torque values can vary. For a standard holder, you might use about 20 to 30 foot-pounds. For a big holder, like a quick-change holder, it can be about 40 to 50 foot-pounds. Always check the instructions that come with your holder for the best numbers to use. Using the right torque helps keep the cutters tight and safe!

How Can Vibration Analysis Be Utilized To Assess The Effectiveness Of Clamping Force In Milling Operations?Vibration analysis helps us check if the clamping force on the workpiece is strong enough during milling. When we mill, the tool can shake or vibrate if it’s not held tightly. We can use sensors to measure these vibrations. If the vibrations are too high, it means the clamping force is not effective. By adjusting the clamping force, we can make the milling work better and safer.

What Role Does Lubrication Play In The Clamping Process Of Milling Cutters, And How Does It Affect The Clamping Force?Lubrication helps make the clamping process smoother for milling cutters. It reduces friction, which means the cutters can fit better and tighter. When there’s less friction, the clamping force is stronger. This helps to keep the cutter in place while it works on the material. So, lubrication is important for a good and safe cut!