Have you ever wondered how a tiny angle can make a huge difference in milling? The milling cutter clearance angle is a crucial factor in how well your tools perform. A proper clearance angle helps in reducing friction. This means your tools last longer and work better.

Imagine you’re trying to cut a piece of cake. If the knife is too dull or not angled right, it’s hard to make a clean cut. The same idea applies to milling cutters. They need the right angle to slice through materials smoothly.

What if I told you that small changes in your milling cutter clearance angle can improve your project? Understanding the tips surrounding these angles can save you time and effort. So, let’s dive into some important tips that can help you get the most from your milling cutter!

Milling Cutter Clearance Angle Tips For Better Performance

Milling Cutter Clearance Angle Tips

Finding the right clearance angle for milling cutters can be tricky. A good angle helps reduce friction and wear. Did you know that a small change in angle can affect your results? For best performance, maintain angles between 5 and 15 degrees. This range balances cutting efficiency and tool life. Remember to consider materials too. Softer materials need less clearance. Experimenting can help you discover what works best. Happy milling!Understanding Clearance Angles

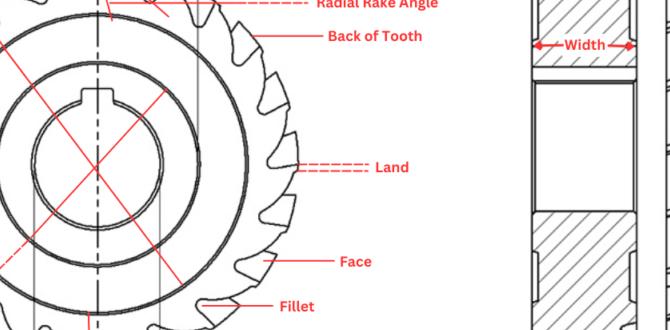

Definition of clearance angles in milling cutters. Importance of clearance angles for machining efficiency.Clearance angles in milling cutters help keep the blade from getting stuck in the material. Think of them as little superheroes for your cutting tools! They allow chips to escape, ensuring a smooth cut and less wear on your tool. This is super important for machining efficiency. Without these angles, you’d be facing a jam like a traffic jam—but worse! With the right angles, you save time, energy, and your sanity.

| Clearance Angle | Importance |

|---|---|

| Prevents binding | Boosts efficiency |

| Reduces wear | Longer tool life |

| Enhances cut quality | Smoother finishes |

Factors Influencing Clearance Angle Selection

Material type and its impact on clearance angle choice. Cutting speed and its relation to clearance angles.Several factors impact how we choose a clearance angle. First, the type of material matters. Softer materials need less clearance. Harder materials require more. This helps to make clean cuts. Second, cutting speed also plays a role. Higher speeds can mean needing a bigger clearance angle. This avoids rubbing and helps the cutter last longer. Finding the right balance is key!

What factors affect clearance angle selection?

Important factors include the type of material and the cutting speed. Different materials cut better with different angles. Higher speeds often need larger angles to prevent problems.

Key Factors:

- Material Type: Soft vs. Hard

- Cutting Speed: Fast vs. Slow

How to Calculate the Ideal Clearance Angle

Stepbystep guide to calculating clearance angles. Examples of calculations for various milling applications.Calculating the ideal clearance angle can enhance your milling projects. Here’s a simple guide:

- Identify the material you are milling.

- Choose the type of cutter you will use.

- Use this formula: Clearance Angle = Relief Angle – Cutting Edge Angle.

- Check the manufacturer’s recommendations for your specific cutter.

For example, if you have a relief angle of 12° and a cutting edge angle of 5°, your clearance angle would be 7°. Each application is different, so adjust accordingly.

What factors affect clearance angles?

Materials, cutting speeds, and cutter designs can all impact the clearance angles.

Impact of Incorrect Clearance Angles on Workpiece Quality

Consequences of improper clearance angles on surface finish. Analysis of wear patterns related to incorrect settings.Using the wrong clearance angle can lead to big problems for your workpiece. You might notice a rough surface finish that looks unappealing. This happens because the tool does not cut as it should. Worn-out tools can create uneven surfaces, making your work look bad.

Here are some effects of incorrect clearance angles:

- Poor surface quality

- Increased wear on tools

- Higher chances of breakage

Understanding these impacts helps you maintain better quality in your projects. Take time to adjust the angles correctly to save yourself future issues!

What happens if clearance angles are wrong?

Surface finish can worsen and tools may wear out faster. This means your work won’t look great and could cost more to fix.

Adjusting Clearance Angles on the Fly

Techniques for adjusting clearance angles during operation. Tools and equipment that assist in modification.Adjusting angles while working can make a big difference. It’s important to get it right. Some techniques help with this during operation. Use a digital protractor for precise readings. A step gauge is also handy for quick checks. You can even use a simple wedge for minor adjustments. Remember to always check your angles regularly for the best results.

What tools help adjust clearance angles?

Tools like digital protractors and step gauges are great for adjusting clearance angles! They ensure you get accurate measurements and can quickly fix any mistakes.

Tools for Adjusting Angles:

- Digital Protractor

- Step Gauge

- Wedges

Case Studies: Successful Milling Applications with Optimal Clearance Angles

Realworld examples demonstrating effective clearance angle strategies. Lessons learned from industries applying optimal clearance angles.Several companies have seen fantastic results by using the right clearance angles on their milling cutters. For example, in the automotive industry, one company adjusted their angle to enhance chip removal. They noticed a drop in tool wear and a rise in productivity. Lessons learned include the importance of testing different angles for various materials. Remember, the perfect clearance angle is like finding the right pair of socks—it makes everything smoother and more comfortable!

| Industry | Clearance Angle Change | Results |

|---|---|---|

| Automotive | Increased from 5° to 8° | 20% less tool wear |

| Aerospace | Modified from 6° to 10° | 15% faster production |

| Construction | Adjusted from 4° to 7° | 30% more efficient cutting |

These examples show how critical it is to have optimal clearance angles. Experimenting can lead to unexpected success! Who knew a little angle could make such a big difference? Keep testing, and may the angles be ever in your favor!

Future Trends in Milling Cutter Design and Clearance Angles

Innovations in milling cutter technology affecting clearance angles. Predictions for the evolution of clearance angle requirements in machining.New technology is changing how milling cutters are designed. Innovations lead to better clearance angles for more precise cuts. Future machines might need sharper angles. This could make the cutting process even smoother and faster. For example:

- Smart coatings will help reduce wear and tear.

- Modular designs allow for easy adjustments.

- Advanced materials can make tools last longer.

Experts believe these trends will shape how we produce things. Each improvement can make a big difference in factories everywhere.

How will clearance angles evolve in machining?

Clearance angle requirements will become more precise. This ensures better performance and longer tool life.Conclusion

In summary, understanding milling cutter clearance angles helps improve your machining results. A proper clearance angle reduces friction and enhances cutting efficiency. You can adjust angles based on your materials and goals. We encourage you to experiment with different settings. For more insights, check out guides on milling techniques and sharp cutting tools to boost your skills further!FAQs

Sure! Here Are Five Questions Related To Milling Cutter Clearance Angles:Sure! Here are five questions about milling cutter clearance angles: 1. What is a milling cutter? A milling cutter is a tool we use to cut shapes into metal or other materials. 2. Why do we need clearance angles? Clearance angles help the cutting tool move smoothly and avoid getting stuck while cutting. 3. How do clearance angles work? They create space between the cutter and the material, making it easier for the cutter to do its job. 4. Are all clearance angles the same? No, different tools have different clearance angles based on what they are cutting. 5. Can you change the clearance angle? Yes, you can adjust the angle when making or sharpening the cutter for better performance.

Sure! Please provide the question you’d like me to answer.

What Is The Significance Of Clearance Angles In Milling Cutter Design, And How Do They Affect Cutting Efficiency?Clearance angles on a milling cutter help it cut better. They let the cutter slide smoothly over the metal. This makes it easier to chop away material without getting stuck. When the angles are right, the cutter works faster and uses less power. So, good clearance angles help you finish your work quickly and easily!

How Do Different Materials Affect The Optimal Clearance Angle To Use For Milling Cutters?Different materials can change how we set the clearance angle on milling cutters. Soft materials, like wood, often need a smaller angle. Hard materials, like metal, usually work better with a larger angle. The right angle helps the cutter cut smoothly and last longer. So, we must choose the angle based on what we are cutting.

What Are The Common Types Of Milling Cutters, And What Clearance Angles Are Typically Recommended For Each Type?Common types of milling cutters include end mills, face mills, and slab mills. End mills usually need a clearance angle of around 5 to 10 degrees. Face mills work best with a clearance angle of about 10 to 15 degrees. Slab mills often require a clearance angle of 15 to 20 degrees. Each type helps cut different shapes and sizes in materials.

How Can Improper Clearance Angles Impact Tool Wear And The Overall Surface Finish Of Milled Parts?Improper clearance angles can hurt tools and make parts look bad. When the angle isn’t right, the tool wears out faster. This can create rough surfaces on the milled parts. We want smooth surfaces, so it’s important to check those angles. If we do, we can make better parts that last longer.

What Adjustments Can Be Made To Clearance Angles To Improve Chip Formation And Control During The Milling Process?To improve chip formation in milling, you can change the clearance angles of the cutting tool. Make the angles sharper so the tool cuts better. This helps create smoother chips that are easier to control. You can also try adjusting the angle slightly to find what works best for your material. Adjusting these angles helps us get cleaner cuts and less mess.