Have you ever wondered how tools shape our world? One tool that plays a big role in manufacturing is the milling cutter. It helps create precise shapes and parts. But did you know that these cutters can lose their sharp edges over time? This is called edge deformation.

Edge deformation can affect how well a milling cutter works. It’s a challenge for many in the industry. Imagine trying to cut with a dull knife. It simply doesn’t work well! That’s why controlling milling cutter edge deformation is so important.

In this article, we will explore how to keep milling cutters sharp and effective. We’ll look at methods to manage edge deformation. You might be surprised at the simple ways to enhance tool life. Let’s dive into the world of makers and see how they tackle this issue!

Milling Cutter Edge Deformation Control: Techniques & Tips

Milling Cutter Edge Deformation Control

Milling cutter edge deformation control is crucial for manufacturing. It helps maintain the shape of cutting tools during operations. This prevents damage and keeps production consistent. Did you know that even tiny changes in the cutter’s edge can affect the final product’s quality? By managing these changes, manufacturers can achieve smoother cuts and longer tool life. Understanding this concept can lead to better efficiency in factories, making work more productive and cost-effective.Understanding Edge Deformation in Milling Cutters

Definition and significance of edge deformation. Factors contributing to edge deformation during milling.Edge deformation refers to the changes in shape at the end of a milling cutter. It is important because it affects the cutter’s ability to work correctly. If the edge is damaged, it can ruin the material being shaped. Several factors can cause edge deformation during milling, including:

- High cutting speed

- Excessive pressure

- Poor tool material

- Improper cooling

Understanding these factors helps in choosing the right tools and settings. It leads to better performance and longer tool life.

What is edge deformation in milling cutters?

Edge deformation in milling cutters happens when the cutting edges change shape from use or pressure. This can lead to poor quality cuts and tool failure. It’s essential to control these deformations for success in milling operations.

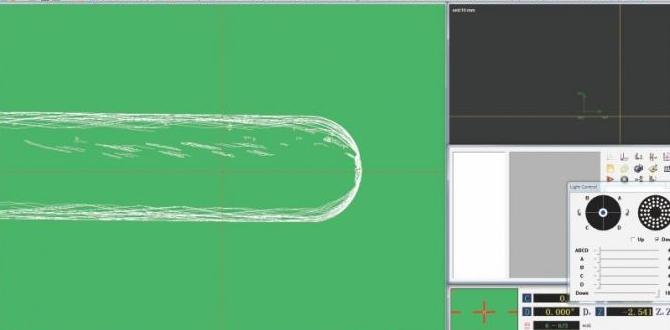

Measurement Techniques for Edge Deformation

Tools and methods for assessing edge deformation. Importance of accurate measurement in deformation control.Understanding how to measure edge deformation is key for successful milling. There are various tools and methods to assess this, including:

- Optical microscopes

- Scanning electron microscopes (SEM)

- Laser scanning

Accurate measurements help control edge deformation, making tools last longer and work better. A small change in edge shape can lead to big differences in performance.

Why is accurate measurement important?

Accurate measurement is crucial for maintaining quality and efficiency in milling operations.

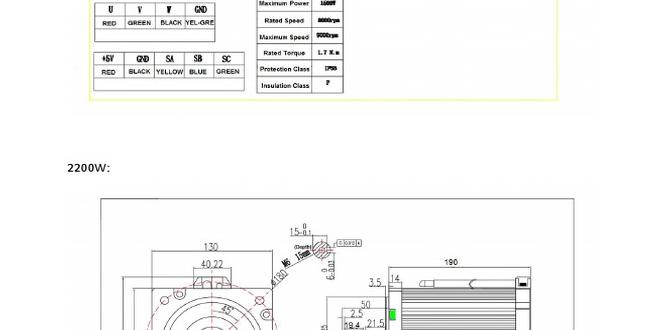

Material Selection for Milling Cutters

Best materials for enhancing edge performance. Impact of cutter material on edge deformation resistance.Choosing the right material for milling cutters is like picking the perfect pizza topping – it can make or break your experience! Good materials boost edge performance and fight against deformation. Tough choices like high-speed steel and carbide shine here. They resist wear and tear, so your cutter stays sharper longer. Remember, poor material choice is like trying to cut a steak with a butter knife – it’s just not going to work!

| Material | Performance | Deformation Resistance |

|---|---|---|

| High-Speed Steel | Good | Moderate |

| Carbide | Excellent | High |

| HSS-Co | Great | Very High |

So, remember, your cutter’s edge performance depends on the material you select. Choose wisely, and avoid the butter knife situation!

Cutting Parameters and Their Effects

Influence of cutting speed, feed rate, and depth of cut. Guidelines for optimal setting to minimize deformation.Adjusting cutting speed, feed rate, and depth of cut can greatly impact machining. Higher cutting speeds can lead to smoother surfaces but may also cause deformation. When you increase the feed rate, it can create more resistance, making the cutter work harder. For optimum results, a shallow depth of cut usually means less stress on the cutter edge. Remember, finding the sweet spot can save you from the “oops, there goes my cutter!” moment!

| Parameter | Effect on Deformation | Optimal Setting |

|---|---|---|

| Cutting Speed | Higher speeds can improve finish but risk melting edges. | Moderate speed is best. |

| Feed Rate | High feed rates increase stress and deformation. | Low to moderate is ideal. |

| Depth of Cut | Shallower cuts reduce edge damage. | Keep it light! |

Design Considerations to Mitigate Deformation

Design strategies in cutter geometry to reduce deformation. Role of tool design in maintaining edge integrity.Creating a good design for milling cutters helps control edge deformation. Some effective strategies include:

- Cutting Angle: Select a sharp angle to reduce stress on the edges.

- Thickness: Make the cutter thicker to add strength and avoid bending.

- Material Choice: Use strong and durable materials that withstand wear.

- Coating: Add coatings to protect against heat and friction.

Strong tool design helps maintain edge integrity. This means the cutter stays sharp and works better for longer, which is good for any project.

How does cutter design reduce deformation?

Cutter design reduces deformation by using better shapes, materials, and protective coatings. This keeps the edges strong and sharp for their tasks.

Preventive Maintenance of Milling Cutters

Regular inspection and maintenance practices. Strategies for extending the life of milling cutters.Keeping milling cutters in good shape is important for smooth work. Regular checks help spot problems before they get worse. Clean the tools and look for wear or damage. Here are some simple tips to extend their life:

- Inspect cutters often to catch issues early.

- Keep everything clean and free from debris.

- Store cutters in a dry, safe place.

- Use the right speed and feed settings while working.

Following these practices will help keep milling cutters sharp and effective. Remember, good care today means better work tomorrow!

How often should milling cutters be inspected?

Inspect milling cutters at least once a week. Regular checks find small problems before they turn into big ones.

Future Trends in Milling Cutter Technology

Innovations in milling cutter design and materials. Predictions for advancements in edge deformation control techniques.New ideas in milling cutter design and materials are changing the game. Companies are using tougher and lighter materials to make better cutters. For example:

- Smart materials that adapt to conditions.

- 3D printing for complex shapes.

Future predictions show improvements in edge deformation control. Cutting edges will last longer and work more efficiently. This will help industries save time and money while ensuring quality. Exciting innovations are just on the horizon!

What is the importance of edge deformation control?

Edge deformation control is vital for keeping tools sharp and lasting longer. It helps in achieving precise cuts, improving product quality, and reducing waste in manufacturing.

Conclusion

In conclusion, controlling milling cutter edge deformation is crucial for better machining. It helps you create precise parts and reduces tool wear. By understanding factors like cutting speed and material, you can improve your results. We encourage you to experiment with different settings and learn more about this topic. Together, we can enhance our skills in milling and achieve great outcomes!FAQs

Certainly! Here Are Five Related Questions On The Topic Of Milling Cutter Edge Deformation Control:Milling cutter edge deformation control helps keep the cutting tool sharp and strong. When we use a milling cutter, it can get bent or worn out. To prevent this, we use special techniques to keep the edges in good shape. This way, the tool cuts better and lasts longer. Taking care of the cutter helps us make better things!

Sure! Just ask your question, and I’ll give you a short and simple answer!

What Are The Primary Factors That Contribute To Edge Deformation In Milling Cutters During Machining Processes?Edge deformation in milling cutters happens for a few main reasons. First, the cutter gets very hot while it works. This heat can make the metal change shape. Second, the force from cutting the material can bend or twist the edges. Finally, if you use the cutter for too long, it can wear down and get damaged.

How Can The Selection Of Material And Coating For Milling Cutters Impact Their Resistance To Edge Deformation?Choosing the right material for milling cutters helps them stay strong and sharp. Some materials are harder and resist bending better. Coatings can also protect the cutters from heat and wear. This means they stay in good shape longer and cut better. So, good materials and coatings help milling cutters work well without getting damaged.

What Role Does Cutting Speed And Feed Rate Play In Minimizing Edge Deformation In Milling Operations?Cutting speed is how fast the tool spins, and feed rate is how quickly it moves across the material. If we choose the right cutting speed, our tool cuts smoothly. This helps prevent bending or changing the shape of the edges. A slower feed rate can also help, as it allows for cleaner cuts. By using the right settings, we keep the edges looking nice and tidy.

What Advanced Monitoring Techniques Can Be Implemented To Detect And Analyze Edge Deformation In Real-Time During Milling?We can use special cameras that take pictures very quickly to see changes in the edges. Sensors can feel tiny movements and send alerts when something seems off. We can also use computer programs that analyze data to spot problems immediately. Finally, we can use sound detection tools that listen for unusual noises during the milling. These techniques help us catch and fix issues right away!

How Do Different Milling Strategies, Such As Climb Milling Vs. Conventional Milling, Affect The Extent Of Edge Deformation Experienced By Cutting Tools?When we use climb milling, the tool goes with the motion of the material. This helps reduce edge deformation, which means less damage to the tool. In conventional milling, the tool goes against the motion, causing more edge deformation. So, climbing is gentler on the tool than conventional milling. Using the right method helps our tools last longer!