Have you ever wondered how some tools last longer than others? One secret might be the milling cutter edge radius. This small feature can make a big difference. It helps the cutter operate better with less wear over time.

Imagine trying to carve a pumpkin with a dull knife. It’s tough, right? Now think about a sharp knife that glides right through. The same idea applies to milling cutters. A well-designed edge radius gives them an advantage. It offers smooth cutting and less friction.

Did you know that the right edge radius can save money, too? When tools don’t wear out quickly, companies spend less on replacements. Isn’t that smart? In this article, we will explore how the milling cutter edge radius works and why it’s crucial for low wear. Get ready to learn about cutting tools in a whole new way!

Milling Cutter Edge Radius For Low Wear: Key Insights

Milling Cutter Edge Radius for Low Wear

Milling cutter edge radius plays a vital role in reducing wear. A smoother edge helps the tool glide through materials better. This means fewer changes are needed, saving time and money. Have you ever wondered why some tools last longer than others? The secret often lies in their design. A rounded edge reduces stress on the tool, leading to longer life. Choose the right milling cutter, and you might be surprised at how much more efficient your work becomes!Understanding Milling Cutters

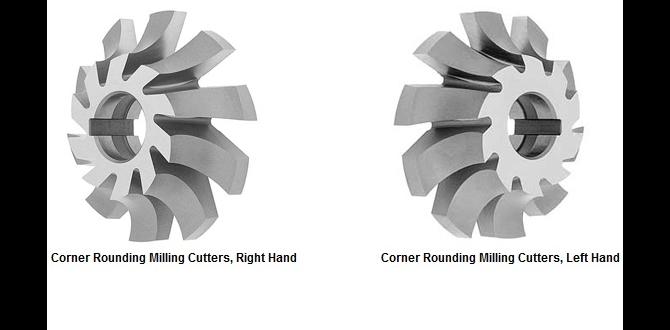

Definition and purpose of milling cutters in machining.. Types of milling cutters available in the market..Milling cutters are vital tools in machining. They help shape materials by slicing away bits like a pizza cutter, but without the cheese. The main goal of these cutters is to create smooth surfaces or specific shapes. There are various types available, each with a unique job. For example, some are designed for delicate work, while others tackle tougher jobs. Here’s a quick look:

| Type of Milling Cutter | Purpose |

|---|---|

| End Mill | Versatile for many tasks |

| Face Mill | Creates flat surfaces |

| Ball Nose Cutter | Great for rounded shapes |

Choosing the right milling cutter can prevent wear and keep your project running smoothly. It’s like picking the right tool from a toolbox—use the right one, and you save time and effort!

The Importance of Edge Radius

Definition of edge radius and its significance in cutting performance.. How edge radius affects tool wear and workpiece finish..Edge radius is the rounded corner of a cutting tool. It is important for how well the tool cuts. A small edge radius can help the tool slice through materials more easily. It also reduces wear on the tool. When the edge radius is just right, tools can last longer and keep workpieces smooth. A well-rounded edge helps prevent chipping and uneven surfaces.

- Cutting Performance: Improves efficiency and quality.

- Tool Wear: Less wear leads to longer tool life.

- Workpiece Finish: Creates smoother surfaces.

How does edge radius affect cutting tools?

The edge radius directly controls wear and finish on parts. A smaller edge often means faster cutting, while a larger edge can give better finish. The right balance helps tools work better for longer.

Factors Influencing Edge Radius Selection

Material considerations for choosing the right edge radius.. The impact of cutting parameters on edge radius efficiency..Choosing the right edge radius for milling cutters involves a few important factors. First, consider the material you are cutting. Harder materials need a stronger edge radius to prevent wear. Second, cutting parameters, like speed and feed rate, greatly affect edge performance. If the speed is too high or the feed is too low, wear can increase. A balanced approach ensures your cutter stays sharp longer.

What should I know about material considerations?

Material type influences edge radius. Hard materials call for a larger radius, while softer ones require a smaller radius for better cutting.

Why do cutting parameters matter?

- Higher speeds can lead to more wear if not managed.

- Proper feed rates help maintain edge sharpness.

Effects of Edge Radius on Tool Wear

How a larger edge radius can reduce wear in specific materials.. Comparative analysis of wear patterns with different edge radii..The shape of a milling cutter’s edge can change how it wears over time. A larger edge radius often helps reduce wear, especially on tough materials. Think of it like wearing rounded shoes instead of pointy toe boots on a rocky path. With softer materials, a smaller edge might work fine. But if you face tougher materials, a larger edge becomes your best buddy.

| Edge Radius | Material Type | Wear Rate |

|---|---|---|

| Small | Soft | Low |

| Large | Tough | Very Low |

Comparing wear patterns is like having a contest! When using a large edge radius, pieces “battle it out” longer without losing their fight. So, if you want to cut down on tool replacement costs, consider giving your cutter a little round makeover!

Recommended Edge Radius for Different Applications

Ideal edge radius for machining various materials (steel, aluminum, etc.).. Applicationbased recommendations for edge radius in milling operations..Choosing the right edge radius is key for successful milling. For steel, a radius of around 0.5mm works great. It keeps wear low and ensures smooth cuts. When tackling aluminum, a smaller radius of 0.2mm does the trick. It helps prevent chipping and boosts finish quality. Always consider your material and goal for the best results.

| Material | Recommended Edge Radius |

|---|---|

| Steel | 0.5mm |

| Aluminum | 0.2mm |

Remember, the right edge radius can be your best friend—unless it tries to borrow money from you!

Monitoring and Maintaining Edge Radius

Techniques for measuring edge radius during maintenance.. Best practices for maintaining optimal edge radius for low wear..Measuring the edge radius is important for keeping milling cutters in great shape. Techniques like using a microscope or a specialized measuring tool help check the radius during maintenance. Making sure the edge is just right can reduce wear. Follow these best practices to maintain the edge effectively:

- Regularly clean the cutter to remove debris.

- Use proper tools for accurate measurements.

- Inspect blades often for signs of wear and tear.

- Adjust cutting angles to keep wear low.

These simple steps can help keep your milling cutter performing well.

How often should you measure the edge radius?

It’s good to measure the edge radius every time you sharpen the cutter. Regular checks keep the cutter in top shape and reduce wear.

Future Trends in Milling Cutter Technology

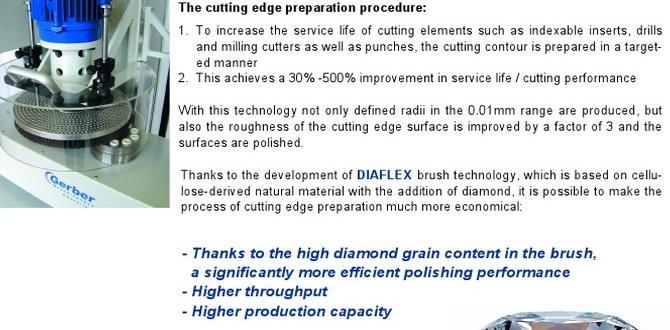

Advancements in materials and coatings influencing edge radius design.. Predictions for the future of edge radius optimization in milling..The world of milling cutter technology is changing fast. New materials and coatings are making milling cutter edges sharper and longer-lasting. These advancements influence the design of edge radii, helping reduce wear during use. As technology improves, we can expect better optimization of these edges for efficiency.

- Stronger materials like carbide enhance durability.

- Advanced coatings reduce friction and heat.

- Future designs will focus on user needs for precision and efficiency.

What advancements are being made in milling cutter materials?

New materials like ceramics and diamond coatings are being used for better performance and lower wear. These changes are making tools last longer and work faster.

As we move forward, the use of advanced technology will shape the future of edge radius design. It will lead to more effective and efficient milling processes, making work easier for everyone.

Case Studies and Success Stories

Realworld examples of businesses that benefited from optimal edge radius utilization.. Lessons learned from ineffective edge radius selection in milling processes..Many companies have found treasure in choosing the right milling cutter edge radius. For example, a car parts manufacturer saw a 30% drop in wear after optimizing their tools. They learned that a sharp edge is not always the best choice. Another company, crafting toys, struggled with high costs due to poor edge selection. Their mistakes cost them time and money, but they turned it around! With the right radius, they saved thousands!

| Company | Benefit |

|---|---|

| Car Parts Inc. | 30% reduction in tool wear |

| Toy Makers Co. | Saved thousands after improving edge. |

Conclusion

In conclusion, choosing the right milling cutter edge radius can reduce wear and extend tool life. A larger edge radius helps cut smoothly and lasts longer. We can make better choices by understanding these concepts. If you’re interested, explore more about milling cutters and their benefits. This knowledge can help you improve your projects and save money!FAQs

Sure! Here Are Five Questions Related To Milling Cutter Edge Radius For Low Wear:Sure! Here are five questions about milling cutter edge radius for low wear: 1. What is the edge radius on a milling cutter? The edge radius is the round part at the tip of the cutter. It helps the cutter cut better. 2. Why do we want low wear on a milling cutter? Low wear makes the cutter last longer. It means we can use it many times before it gets dull. 3. How does edge radius affect cutting? A bigger edge radius can cut in a smoother way. It helps make nicer edges on the materials we cut. 4. When should we choose a smaller edge radius? A smaller edge radius is good for cutting harder materials. It helps the cutter stay sharp longer. 5. Where can I learn more about milling cutters and their uses? You can read books or watch videos online. Many websites have helpful information about tools like milling cutters!

Sure! Please provide the question you would like me to answer.

How Does The Edge Radius Of A Milling Cutter Affect Tool Wear And Lifespan During Machining Operations?The edge radius of a milling cutter is how round the cutter’s edge is. When the edge is round, it spreads the pressure evenly. This helps the cutter last longer and wear down slower. If the edge is sharp and pointy, it can wear out quickly. So, a round edge means less wear and a longer lifespan for the tool.

What Materials Are Typically Best Suited For Milling Cutters With Optimized Edge Radii To Minimize Wear?The best materials for milling cutters are high-speed steel (HSS) and carbide. HSS is tough and can handle heat well. Carbide is very hard and lasts a long time. These materials help the cutters keep their shape and last longer while they work.

How Does The Choice Of Cutting Parameters, Such As Speed And Feed Rate, Interact With The Edge Radius To Influence Wear Rates?The speed and feed rate are important when cutting materials. Speed means how fast the tool moves, and feed rate is how much the tool bites into the material. If the speed is too high or the feed rate is too low, it can create more heat. This heat can make the edge of the tool wear out faster, especially if the edge is rounded. So, you need to choose the right speed and feed rate to help the tool last longer!

What Are The Advantages And Disadvantages Of Using A Larger Edge Radius Versus A Smaller Edge Radius On Milling Cutters In Different Applications?Using a larger edge radius on milling cutters can make cuts smoother and help prevent chipping. This is great for softer materials. However, it can be hard to make sharp details. A smaller edge radius creates sharper cuts, which is good for detailed work. But it may wear out faster and chip more easily. So, you need to choose based on what you are cutting!

How Can Manufacturers Accurately Measure And Control The Edge Radius Of Milling Cutters To Ensure Consistent Performance And Reduced Wear?Manufacturers can measure the edge radius of milling cutters using special tools like calipers or microscopes. They check the edges carefully to see if they are the right shape. To control the edge radius, we can change how we make the cutters. This helps keep them sharp and working well for a long time. Regular checks make sure everything stays consistent.