Have you ever wondered how manufacturers make precise cuts in metal? They use special tools called milling cutters. These tools are essential in factories and workshops. But with time, they wear out. When this happens, it’s important to measure how much they have worn down. This is where the milling cutter flank wear measurement tool comes in.

Imagine you’re building a model airplane. If your scissors are dull, your cuts become messy. The same applies to milling. A worn milling cutter can ruin a perfectly good project. It affects the size and quality of every cut. In the world of manufacturing, this can lead to mistakes and wasted materials.

Surprisingly, a small tool can make a big difference. Measuring the wear on a milling cutter helps keep everything running smoothly. This simple step ensures that the tools work effectively. So, how do experts use this tool to measure wear? Let’s explore the fascinating world of milling cutter flank wear measurement tools together!

Milling Cutter Flank Wear Measurement Tool: Importance & Usage

Milling Cutter Flank Wear Measurement Tool

Measuring flank wear on milling cutters is crucial for effective machining. This tool helps understand how well a cutter performs over time. Did you know that wear can affect the quality of your work? Regular measurement can save time and money. With accurate readings, you can schedule maintenance before a cutter fails. This proactive approach improves productivity and ensures better results in every project. Who wouldn’t want to work smarter?Understanding Milling Cutter Flank Wear

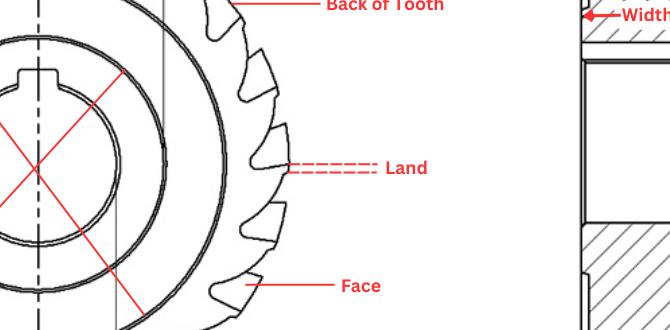

Definition of flank wear in milling cutters. Causes and implications of flank wear on machining performance.Milling cutters are like warriors in the machining battle. Their flank wear shows how worn out they become after facing tough materials. Flank wear occurs when the side of the cutter wears down, usually due to friction and heat. This can spoil your cutting performance, just like a knight with a dull sword! Key causes include insufficient cooling and high cutting speeds. The outcome? Slower speeds and poor finishes that can make anyone a little cranky.

| Cause | Effect |

|---|---|

| High cutting speeds | Increased flank wear |

| Poor cooling | Heat buildup |

| Incorrect tool materials | Faster wear rates |

Keeping an eye on flank wear helps ensure your cutting tools stay sharp! Just ask any seasoned machinist, and they’ll tell you: a happy cutter means happy parts.

Importance of Measuring Flank Wear

Impact of flank wear on tool life and product quality. Benefits of timely wear measurement in milling operations.Measuring flank wear is crucial in milling operations. Flank wear affects tool life and product quality. If wear is too high, tools break faster, leading to more downtime. This can cost time and money. Proper measurement helps prevent such issues. It also ensures smoother cuts and better finishes.

Benefits of timely wear measurement include:

- Longer tool life.

- Higher-quality products.

- Less machine downtime.

Remember, checking wear often can save you headaches later!

Why is measuring flank wear important?

Measuring flank wear is essential to ensure that tools last longer and parts are made with high quality. Regular checks can prevent tool failure and improve overall efficiency.

How to Use Flank Wear Measurement Tools

Stepbystep guide to measuring flank wear. Best practices for accurate measurements.Measuring flank wear can seem tricky, but it’s not rocket science! First, grab your flank wear measurement tool. Clean the cutting tool and set it evenly in your measuring device. Adjust until it’s snug. Now, turn on the tool and let it give you the readings. Don’t forget, accuracy is key! Poor measurements could make you think your cutter is past its prime, like an old banana!

| Step | Action |

|---|---|

| 1 | Gather your tools |

| 2 | Clean the cutter |

| 3 | Set it in the measurement tool |

| 4 | Turn it on |

Best practice? Measure three times for that sweet accuracy. If it feels like guessing, you’re probably doing it wrong. Keep those measurements consistent, and your milling cutter will thank you!

Interpreting Flank Wear Measurements

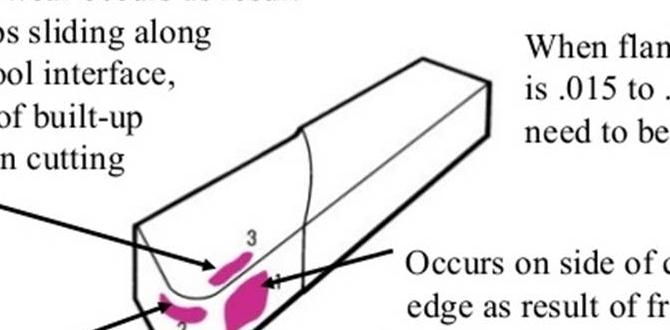

Understanding wear patterns and what they indicate. Correlating measurements with machining parameters.Understanding how wear forms on milling cutters can help us improve performance. Different wear patterns show what might be wrong during cutting. For example, flaking can mean a tool is too hot. Overall wear can connect with many factors like speed, material, and pressure.

- Cutting speed affects how quickly a tool wears.

- Material type can change wear rates.

- Pressure applied can cause more or less wear.

Making sense of these factors helps us adjust machine settings for better tool life.

Why is flank wear important?

Flank wear shows how well a milling cutter performs. It helps predict when the tool may need replacement.

Key insights on flank wear:

- Low wear means better cutting efficiency.

- High wear suggests adjustments are needed.

Common Challenges in Flank Wear Measurement

Typical issues encountered during measurement. Solutions and tips for overcoming these challenges.Measuring flank wear can be tricky. One common issue is getting a clear reading due to tool vibrations. A shaky measurement is like trying to read a book on a roller coaster—not fun! Using a sturdy setup can help. Another challenge is lighting conditions. Poor light can hide wear. A portable light can be a game changer. If you’re unsure, using a good measurement tool can make all the difference.

| Challenge | Solution |

|---|---|

| Tool vibrations | Use a stable setup |

| Poor lighting | Bring a portable light |

| Unclear readings | Invest in quality tools |

Case Studies and Real-World Applications

Examples of successful flank wear measurement in various industries. Lessons learned and best practices from these case studies.Many industries face challenges when measuring flank wear on milling cutters. Successful examples show how companies improved their performance. For instance, a car manufacturer used precise tools to track cutter wear. This practice reduced costs and increased production speed.

- Lessons learned include:

- Consistency in measurement is key.

- Regular checks prevent unexpected downtime.

- Training staff on using measurement tools pays off.

Using real-world examples proves that milling cutter flank wear measurement tools can lead to better outcomes. These tools help companies work smarter and get better results in their projects.

What are the benefits of flank wear measurement tools?

Flank wear measurement tools can improve efficiency and reduce costs in manufacturing processes. They help track tool life and ensure products meet quality standards.

Conclusion

In summary, a milling cutter flank wear measurement tool helps you check tool wear accurately. This ensures better machine performance and longer tool life. By using this tool, you can improve your work quality. We encourage you to explore more about it and consider adding it to your toolkit. Understanding wear can help you make smarter choices in your projects!FAQs

What Are The Common Methods Used To Measure Flank Wear On Milling Cutters?To measure flank wear on milling cutters, we often use a tool called a microscope. This helps us look closely at the edges. Sometimes, we also use a device called a caliper to measure the wear directly. Another way is to compare the cutter to a set of worn tools in a chart. Each method helps us understand how much the cutter has worn down.

How Does Flank Wear Affect The Performance And Efficiency Of Milling Operations?Flank wear happens when the edge of a cutting tool gets worn down. This makes it less sharp, which means it can’t cut as well. If you keep using a worn tool, your work might take longer and be messier. So, you want to check and change tools often for better and faster milling results.

What Are The Advantages And Disadvantages Of Using Optical Measurement Tools For Assessing Flank Wear?Using optical measurement tools to check for flank wear has good and bad points. The good part is that these tools can give very clear and precise images. This helps us see tiny changes easily. However, the downside is that they can be expensive and may not work well in all lighting conditions. Also, using them can take time and needs careful handling.

How Can The Data Obtained From Flank Wear Measurements Be Used To Optimize Milling Processes?We can use flank wear measurements to check how much the tool is getting worn down. By knowing this, we can change how we mill things to make the tool last longer. For example, we might change the speed or type of material we’re using. This way, we save money and get better results in our projects.

What Role Do Cutting Parameters Play In The Rate Of Flank Wear On Milling Cutters?Cutting parameters are things like speed, depth, and feed rate when using a milling cutter. They affect how fast the cutter wears down. If you cut too fast or too deep, the cutter wears out quicker. Finding the right settings helps the cutter last longer. So, you want to use careful settings to keep your tools sharp!