Have you ever wondered how factories cut super tough metals? It’s not that simple! One important tool in this process is the milling cutter. This special tool helps shape and remove metal from complex parts. But what makes a milling cutter great for hard-to-machine metals?

Imagine trying to craft a sculpture from rock. You need the right tools to get the job done. The same goes for machining metals that resist cutting. Using the right milling cutter can make all the difference. Did you know some milling cutters can last ten times longer than their regular counterparts? That’s impressive!

In the world of manufacturing, having the right tools means success. With the right milling cutter, even the hardest metals can be shaped into finely crafted parts. This article will explore how these tools work and why they are essential for tough jobs. Get ready to dive into the world of milling cutters and discover their magic!

Milling Cutter For Hard-To-Machine Metals: Choosing The Best Options

Milling Cutter for Hard-to-Machine Metals

Are you curious about how to work with tough metals? A milling cutter for hard-to-machine metals can make a big difference. These special tools help shape and cut strong materials like titanium and stainless steel. With the right milling cutter, you can achieve cleaner cuts and faster production times. Did you know that using the wrong cutter can damage your machine? Choosing the right one is key. Explore how these cutters transform challenging tasks into easier, manageable projects!Understanding Hard-to-Machine Metals

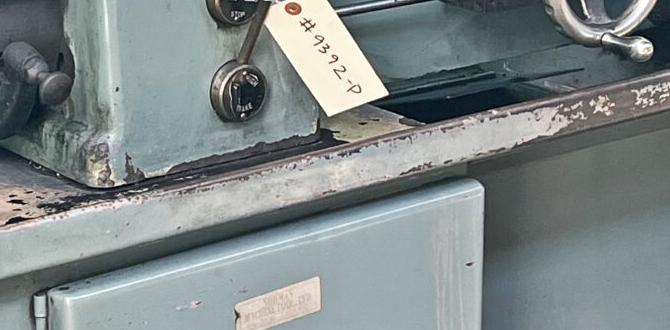

Definition and characteristics of hardtomachine metals. Common examples in various industries.Hard-to-machine metals are special metals that don’t like to be cut or shaped easily. They are tough and require extra help when being processed. Think of them like moody cats; they won’t budge without a good reason! Common examples include titanium, tool steel, and some stainless steels. These metals are often found in industries like aerospace, automotive, and medical because they are strong and last long.

| Metal Type | Industry Example |

|---|---|

| Titanium | Aerospace |

| Tool Steel | Manufacturing |

| Stainless Steel | Medical Devices |

Material Composition of Milling Cutters

Common materials used in milling cutter manufacturing. Advantages and disadvantages of each material.Milling cutters come in various materials. Each has its own strengths and weaknesses. Here are some common types:

- High-Speed Steel (HSS): Strong and tough. Great for general use. But less durable than carbide.

- Carbide: Very hard and heat-resistant. Ideal for hard metals. However, it’s more brittle and can break easily.

- Cobalt: Tough and heat-resistant. Works well in high-speed jobs. Yet, it is pricier than HSS.

- Ceramic: Holds up well under heat. Perfect for fast cutting. But it can chip if used incorrectly.

Knowing these materials helps choose the right milling cutter for your needs.

What are the common materials used in milling cutters?

Common materials include High-Speed Steel (HSS), Carbide, Cobalt, and Ceramic. Each material has unique qualities for different cutting jobs.

Choosing the Right Milling Cutter for Hard-to-Machine Metals

Factors to consider (geometry, diameter, tool life). Matching cutter type with specific metal properties.Selecting the right milling cutter is key for working with hard-to-machine metals. Several factors impact performance. Consider the geometry, diameter, and tool life. Each metal type also needs a specific cutter style. Match the cutter to the metal’s hardness and strength for better results.

- Check the cutter’s shape for the job.

- Choose the right diameter for better stability.

- Look for a long tool life to save time and money.

Using the right cutter can make your work easier, faster, and more accurate.

What factors affect the milling cutter choice?

Geometry, diameter, and tool life play important roles. Each must match the specific metal type for the best results.

Cutting Parameters for Optimal Performance

Recommended cutting speeds and feeds. Importance of coolant and lubrication during machining.Finding the right cutting speeds and feeds can feel like solving a tricky puzzle. For hard-to-machine metals, higher speeds often work best, but be careful! Too fast can lead to disaster. Coolant and lubrication are your best friends. They keep things cool and reduce wear on your tools. Imagine trying to fry an egg without oil! Here’s a quick reference table:

| Material | Cutting Speed (SFM) | Feed Rate (IPR) |

|---|---|---|

| Steel | 100-200 | 0.005-0.012 |

| Titanium | 50-150 | 0.003-0.006 |

| Copper | 200-500 | 0.010-0.020 |

Remember, choosing the right parameters not only makes your tools happy, but they also help you achieve smooth and precise cuts. So, keep those speeds moderate, and don’t skip the coolant! Your tools will thank you—and so will your projects!

Common Challenges and Solutions

Issues faced while milling hard metals. Effective solutions and best practices.Milling hard metals can feel like wrestling a bear while riding a unicycle. Challenges pop up, like tool wear and chip buildup. These can slow down your work and test your patience. To tackle these issues, choose the right milling cutter and keep your tools sharp. Cooling during the process is also key—like giving your tools a nice cold drink! Here are some effective solutions:

| Challenge | Solution |

|---|---|

| Tool Wear | Use high-quality materials and lubricants. |

| Chip Buildup | Increase the feed rate and adjust cutting speeds. |

| Heat Generation | Implement proper cooling techniques. |

By applying these tips, you’ll tackle tough metals like a pro! Remember, persistence pays off, even if your cutting tool throws a tantrum!

Future Trends in Milling Cutters

Innovations in milling technology. The impact of advanced manufacturing methods on cutter design.Exciting changes are happening in milling technology! New ideas are making milling cutters even better. Smart design changes help machines cut tough metals like butter. Manufacturers are using advanced methods, making tools sharper and more durable. One innovation is coatings that make cutters last longer while reducing wear. It’s like giving your tools a superhero cape!

| Innovation | Impact |

|---|---|

| Coated Cutters | Longer life, less wear |

| Smart Technology | Precise cutting, less waste |

| Unique Designs | Better performance on hard metals |

With these changes, the future of milling looks bright and shiny. Who knew cutting metal could be so cool? Let’s hope for more innovations, so our tools can keep impressing us!

Case Studies and Applications

Examples of successful milling operations on hard metals. Lessons learned from industry practices.Many companies have thrived using milling cutters for tough metals. One factory cut time to make parts by 30% after changing cutters. They used better materials and improved speeds. Another company got fewer mistakes in products by switching to a different design of milling cutter. They found this out by testing various shapes and sizes. These stories show how thinking outside the box can lead to great results.

What lessons can we learn from successful milling operations?

Key lessons include testing different tools, focusing on quality, and analyzing results. These steps help businesses create better products faster and cheaper.

Conclusion

In summary, using a milling cutter for hard-to-machine metals is essential for precision and efficiency. Choose the right cutter for your material. Consider coatings that enhance performance. Remember, understanding your tools helps you make better decisions. We encourage you to explore more about milling techniques and materials. Dive deeper to improve your skills and create amazing projects!FAQs

What Are The Key Characteristics Of Milling Cutters Designed Specifically For Hard-To-Machine Metals?Milling cutters for hard-to-machine metals are strong and sharp. They often have special coatings to prevent wear. These cutters are made from tough materials, like carbide, to last longer. They also have unique shapes to remove metal better. You can use them for precise cuts in tough metals easily.

How Does Cutting Tool Material Impact The Performance And Durability Of Milling Cutters When Machining Hardened Alloys?The material of the cutting tool affects how well it works and how long it lasts. Strong materials like carbide can cut through hard metals better than weaker ones. This means the tool won’t wear out quickly and can make clean cuts. If you choose the right material, your milling cutter will last longer and make your job easier.

What Milling Techniques Or Strategies Can Be Employed To Optimize The Machining Of Hard Metals With Specialized Cutters?To make cutting hard metals easier, you can use special techniques. First, choose the right cutter; these are tools that shape or cut metal. You can also use slower speeds when cutting. This helps the cutter last longer. Lastly, adding coolants, like water or oil, keeps things cool and helps cut better.

How Do Coatings On Milling Cutters Enhance Their Ability To Cut Through Hard-To-Machine Materials?Coatings on milling cutters make them stronger and last longer. They help the cutters slide through tough materials easily. The coatings can also protect against heat and wear. When we use coated cutters, we get better cuts and save time. This means our work becomes smoother and faster!

What Advancements In Milling Cutter Technology Have Been Developed To Improve Efficiency And Precision When Working With Difficult-To-Machine Metals?Milling cutters are getting better every day to help us cut tough metals more easily. New materials make the cutters last longer and work faster. Special coatings help the cutters stay sharp, which means better cuts. We can also use newer shapes for the cutters, making them more precise. These changes save time and help us do a great job!